Anyhow,

the overall work was very entertaining since besides building up the

model,

I had to solve a couple of puzzles that arose due to the mechanical

problems.

For example, I chose the working suspension option and was disappointed

to have the car with a fully flat dead suspension since the poor

plastic

torsion bars could not give the required torque. My solution was to

open

up the shock absorbers and put helical springs on their pistons to take

the load.

This

is the bottom-rear view showing the rear suspension details. The

transverse

reaction bar is also another weak item that buckles and tends to break

if you be a bit careless. However, the hoses and electrical harness are

from soft rubber and give very good detail if you can stick them

properly.

I used cyanoacrylate adhesive for fixing rubber for its definite fixing

properties.

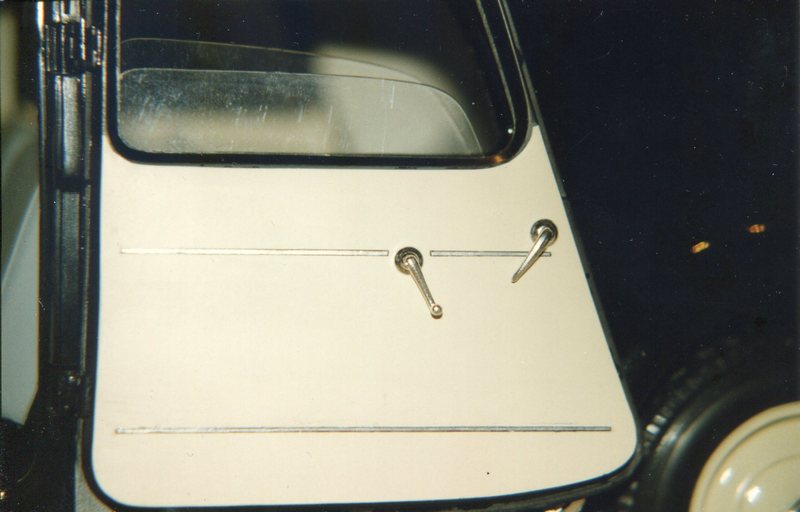

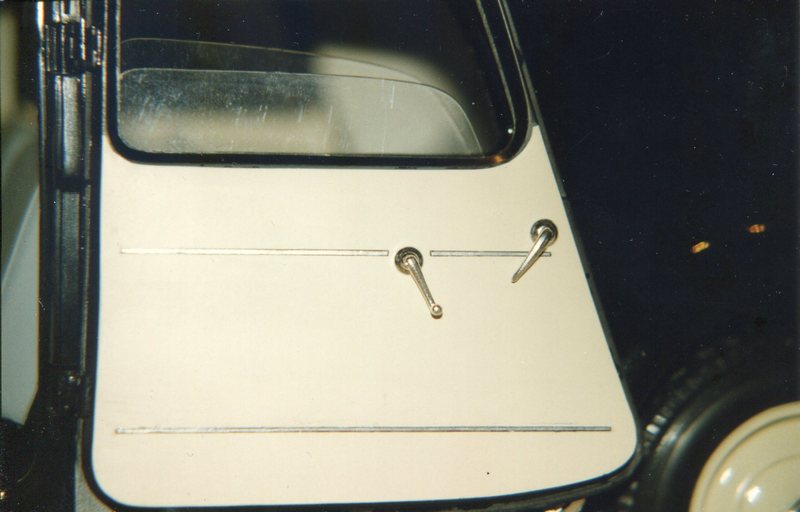

The

door handles both in and out, are connected to the door lid that keeps

the door in place. The door-glass raiser arm is dummy. The original

model

suggested 3 fixed level choices for the glass; I made it variable by

putting

a soft padding within the door so that it exerts some force on the

glass

and keeps it at where you left it.

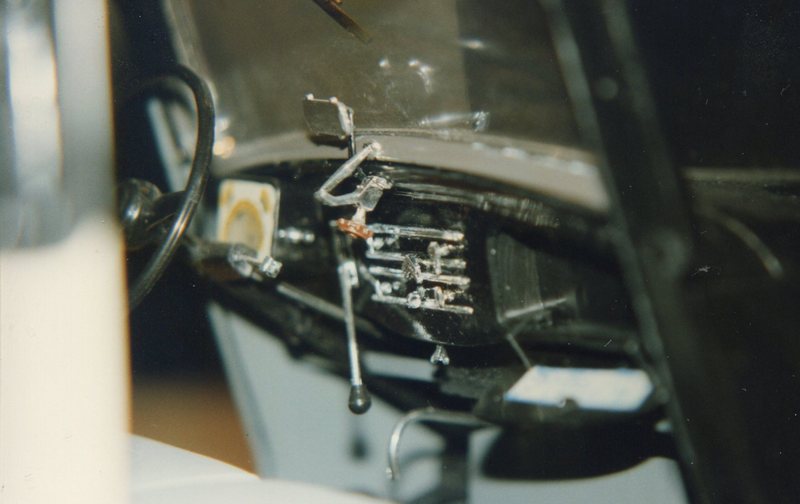

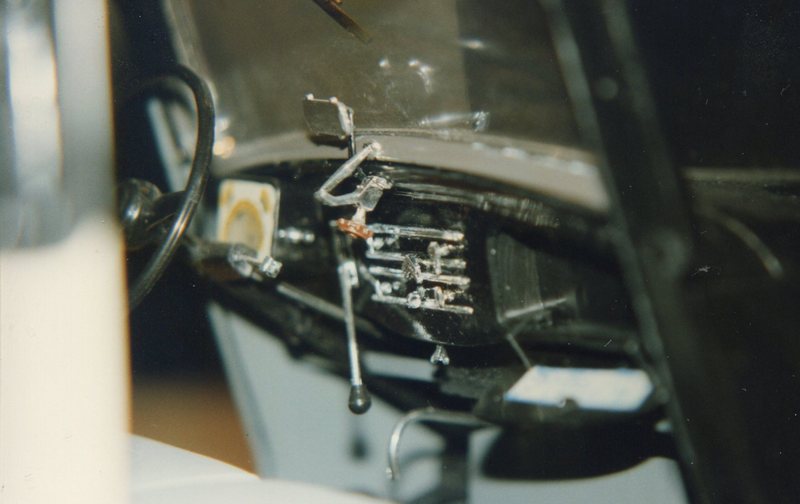

Very

fine dashboard panel details. The glovebox lid opens as well and has a

turning lock to keep it in place. It

was a pity that the model had to be painted black all over for the sake

of authenticity. The black color simply disguises all the fine details

put into the model.

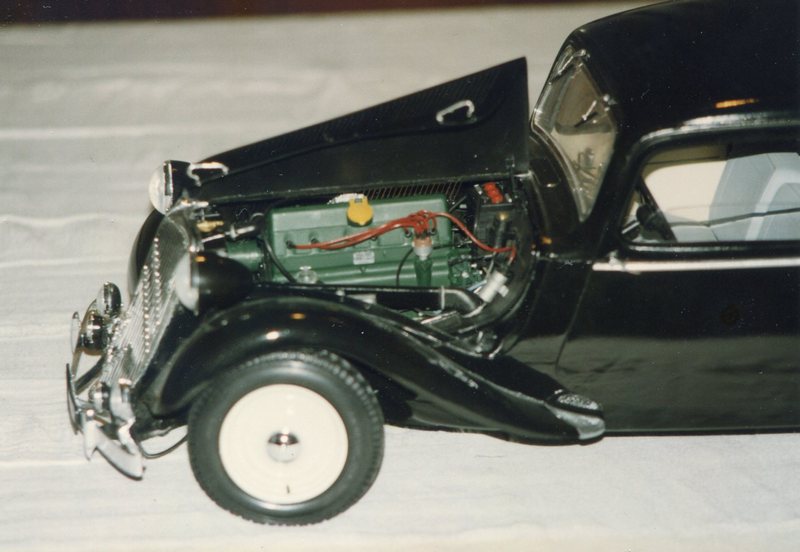

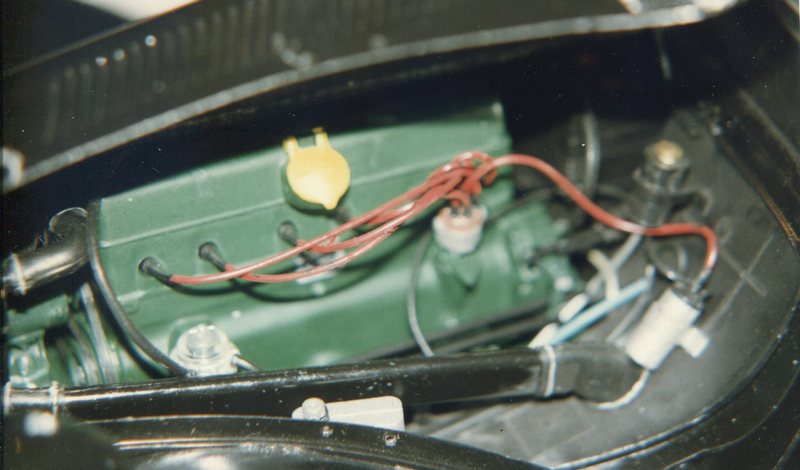

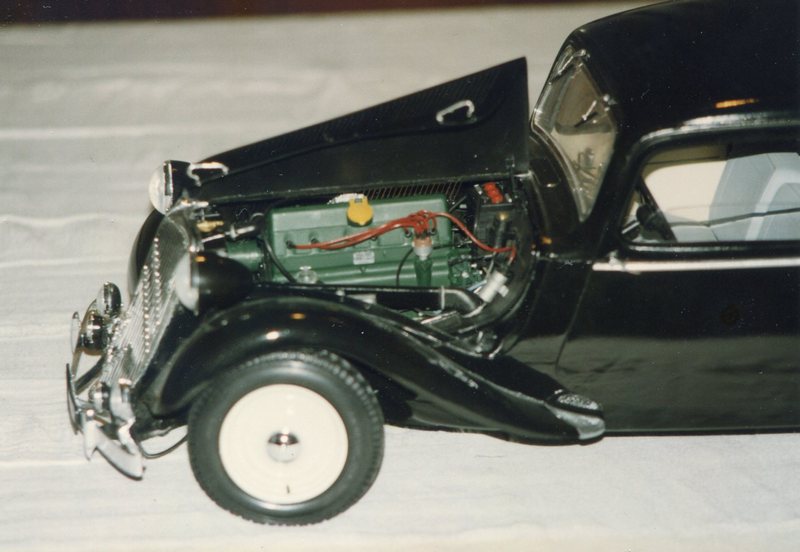

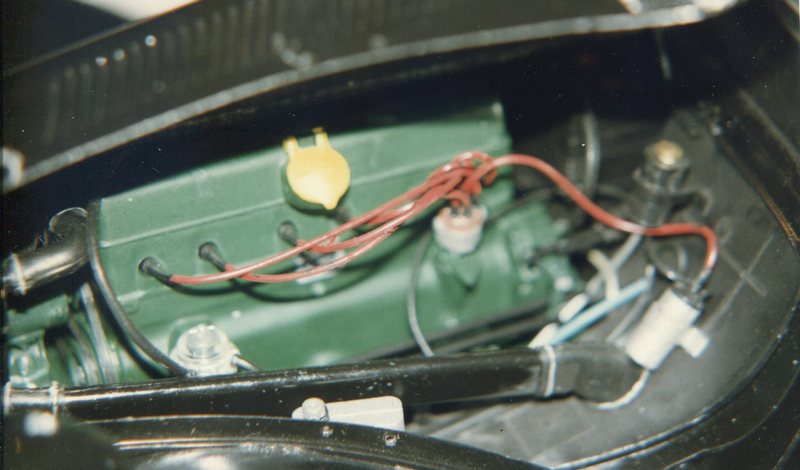

The

engine compartment is also full of details. Another physical weakness

here

was that the center hinge of the two-piece engine hood came out of its

glued position whenever one of the sides was opened. My solution was to

drill the ends of the hinge through the body panel, insert a steel pin

(cut to the appropriate length ) and fix it at the back with epoxy

adhesive.

The headlamps were also standing on a very weak connection, so I

inserted

a brass rod through its base to take up the load.

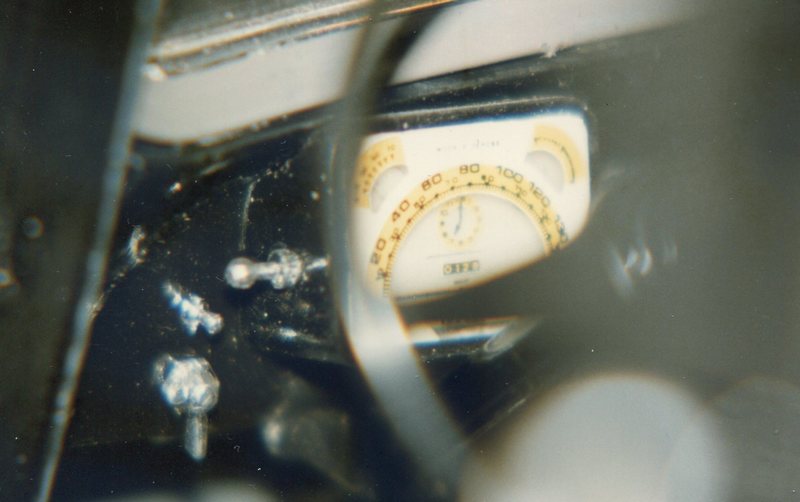

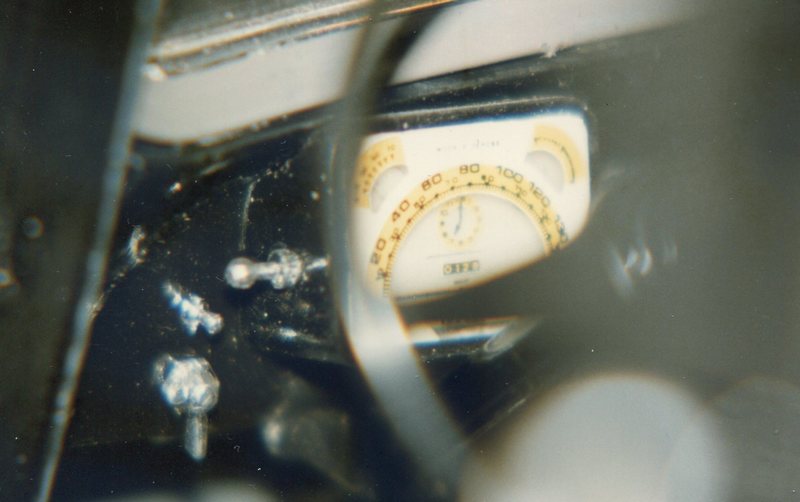

The

speedometer is a replica of the original in the sense that

you mount

it layer by layer as if you are mounting the real one. The

steering

box and the whole system would work if the long plastic steering shaft

could withstand the torque. I now regret that I did not substitute a

brass

rod for that item. So now you can only steer by using the front wheels

themselves.

Not

every fault came from the model itself! It was perfectly me

who cut

the roof lining somewhat short. To make up for that

mistake,

I tailored the lining from artificial leather, put brass rods for

tensioning

tranversely and fixed the whole lining to the pillar construction by

the

aid of that tension...

Well,

that was how it was originally made . At least, it may be considered

authentic

by the way of manufacturing!

Unfortunately,

looking closer to the ceiling lamp shows that excessive tension has

released

the texture from the backside of the lamp.

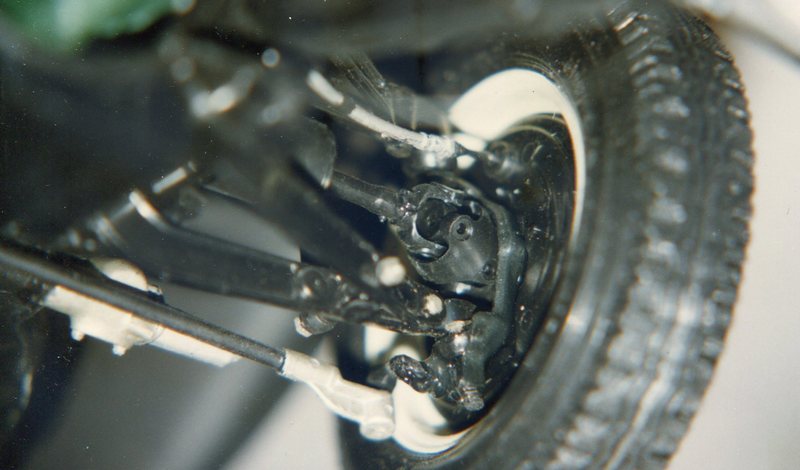

This

is the frontal view of the front suspension cradle. You notice that on

the left, the pivoting bar of the lower wishbone is greyish in color.

The

reason is that, while trying to apply greater torque to the torsion

bars,

it broke and I made an identical part from aluminium. It was then I

inserted

steel springs in the shock absorbers and made the suspension work.

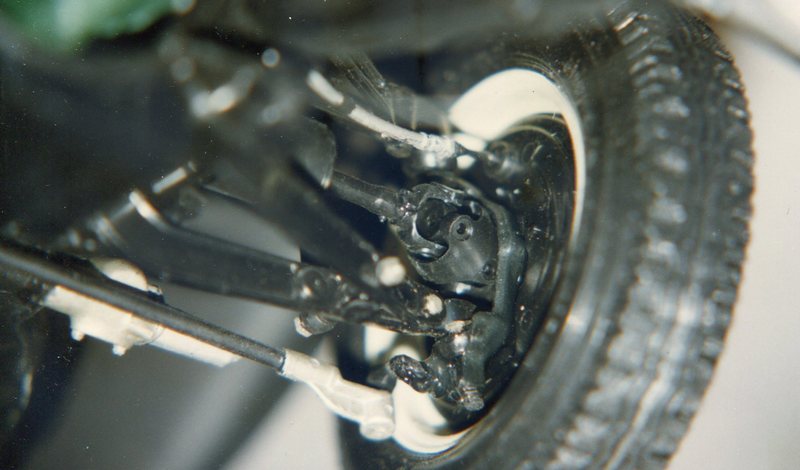

This

is the front wheel drive system detail. The double cardan universal

joint

not only works radially, but slides along its shaft keys with

suspension

motion.

And,

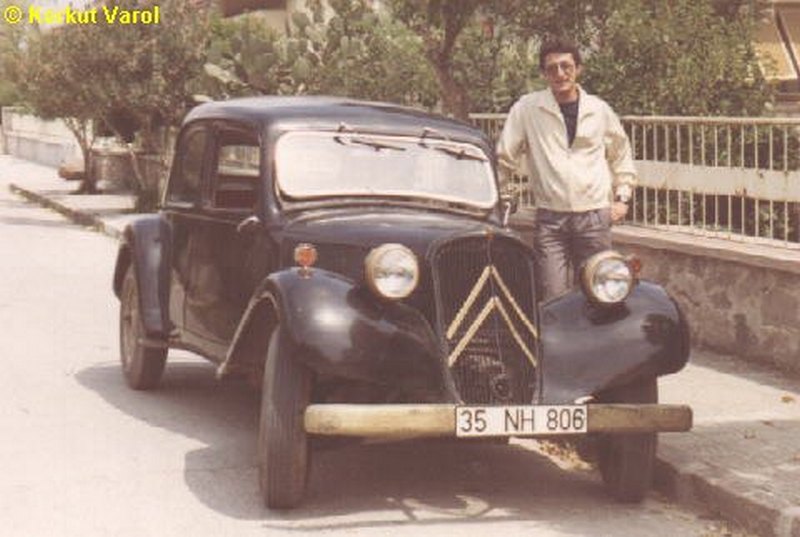

finally, this is me and my 1 / 1 scale Citroen(1949) in 1980.

Unfortunately,

I don't own this car now and I regret that I sold it. It has a distinct

place in my memory and what I now have are its pictures plus 1/8 - 1/24

- 1/43 scale models.