Die-cast

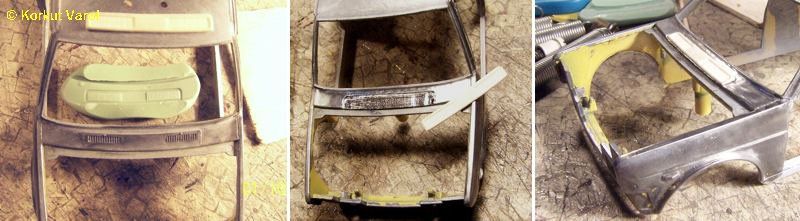

and Italeri's 131 Abarth bodies side by side. I will use the boot lid

from the Abarth body to replace the unauthentic boot lid of the

die-cast.

12 August 2011:

I drew the parting

lines of the boot lid, front fender and front door.

13

August 2011:

I

dismantled the body and removed the paint by automotive paint remover.

I

engraved the parting lines of the front fender and door with Dremel

engraver.

14 August 2011:

I

removed the metal from the boot opening with Dremel cutter. I also cut

the boot lid off from the Abarth body and scraped the rear spoiler.

28 June 2011:

I

trimmed the rear opening until only the window rubber was left.

I

sanded the parts until the boot lid fit in the opening properly.

04 September 2011:

The

scripts on the back and side rear panels were big in proportion, and

different from the Turkish production; so I shaved them off.

The door handles

were too highly cast, so I shaved them proportionally.

02 October 2011:

The

air intake grille region on the cowl was out of proportions, so I

copied from Italeri's Abarth which was far better than the diecast one.

The part I cast would stand too high on the present cowl, so I machined

the region and glued the part in with CA glue.

04 October 2011:

I filled the hole

in the boot lid, applied putty and sanded. Then I glued the boot lid in

place with CA glue.

08

June 2012:

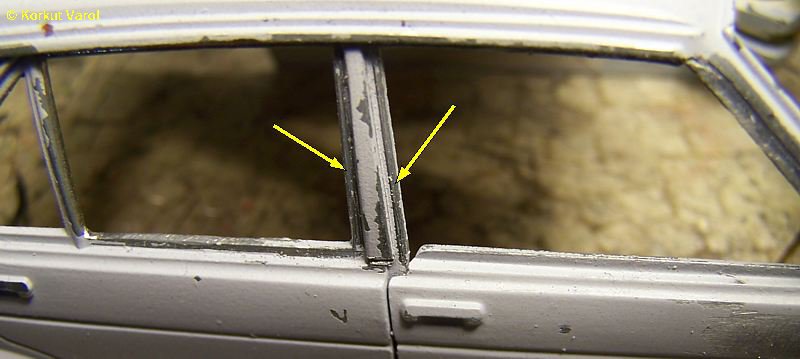

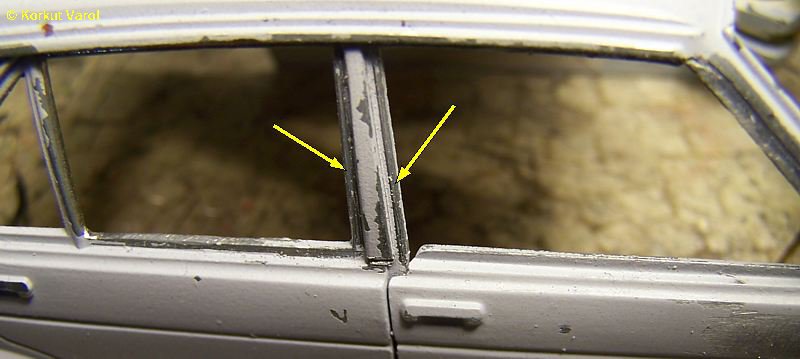

The side window

frames and the B-post should be the same level, however they were not;

so I had to make some corrections.

I manufactured the

frame-fillers with brass sq. section at the front and styrene strip at

the rear.

Reason:

Different required thicknesses at the front and rear.

I

also added the quarter-glass bar at the front, which was present in

early Turkish made productions.

After

finishing the window frames, I cut the front end so that the front

grille will fit and closed the unnecessary openings with putty.

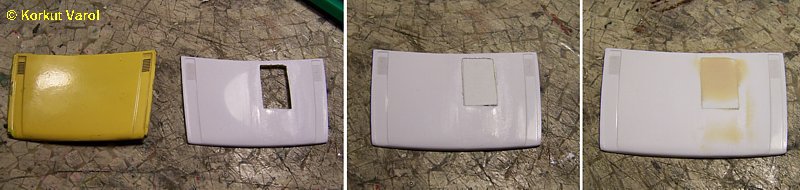

10 June 2012:

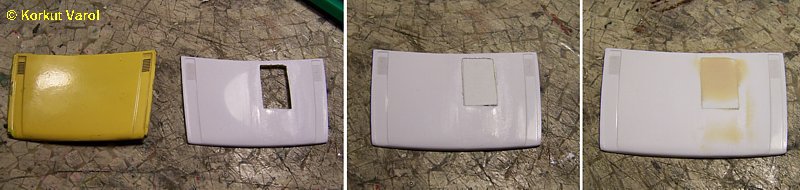

I

did not like the details of the die-cast hood and the grilles on it, so

I decided to use the hood of Italeri kit. I cut off the air intake,

glued a piece of styrene and applied putty and sanding.

29 December 2012:

Before

pouring the silicone mold, I fixed the hood and the glasses on the body

and sealed every joint with Testors clear part cement to prevent

silicone leakage. I fixed the master model in the silicone-pouring box

with UHU Patafix, then I poured the RTV silicone in the box.

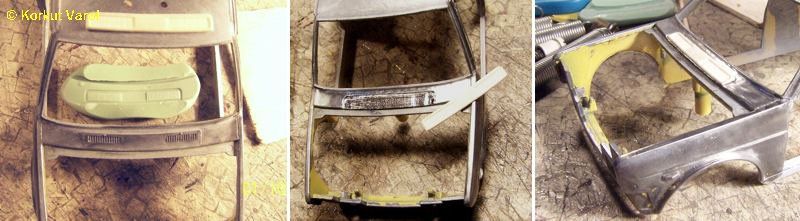

03 February 2013:

After

the female mold was ready, I prepared a male mold and cast the first

sample. However, this sample proved to be too thick in the shell, so I

thinned the body shell by removing material. Then, using this shell, I

made the male mold.

Pictures of the second cast body

shell.

I prepared the instrument panel

for casting, made the mold and cast a resin part.

..................

..................