|

|

(

Read as "Dolmoosh" )

Page 2 of 7

Dec. 20, 2003:

I glued a strip below the rear window opening to complete the upper part of the back door panel, and another thin one at the skirt for the proper panel profile.

Dec. 21, 2003:

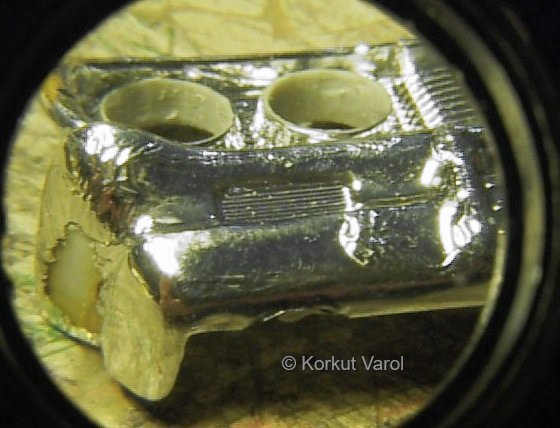

Jumping to another branch, I drilled the cast-in chrome headlamps. I will put in scratchbuilt reflectors and lenses.

Dec. 24, 2003:

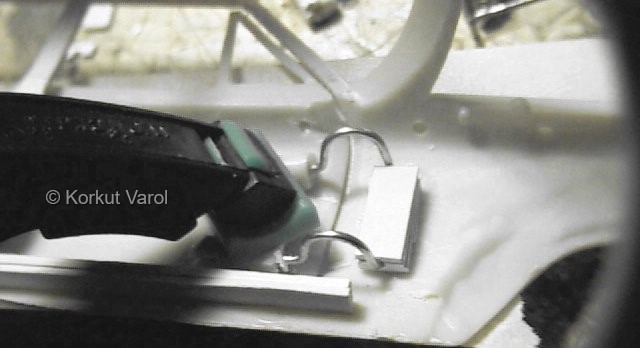

Now to the front door hinging. I prepared the hinge arms from paper clip wire and the bearing from styrene sheets as shown.

Here is the assembled view.

But I made a mistake and the hinge arms were too wide apart, when the mating blocks were installed, they proved to be longer than the door height! So I dismantled the members, manufactured shorter hinge arms and shortened the housings accordingly. With the mating blocks, the assembly looks like this.

Dec. 25, 2003:

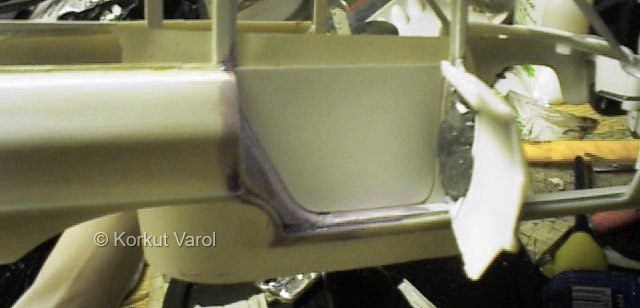

I glued the housing and arms to the inside of the fender, by testing the opening.

Then I put the door in place, fixed it on the outside with masking tape, and glued the mating blocks on the inside of the door.

The door now opens and closes properly. The good point in constructing like this is, I can easily take out the door anytime I want.

The right front door was done in the same manner, and shown in the right pic.

I cut out recesses in the sides of the chassis panel so that the the parts I added on the body would fit in.

Dec. 27, 2003:

Forming the inside panel of the rear door. I cut a styrene sheet to fit in the door void, and to rest on the tiny flanges of the B and C posts.

I put the door inner panel in place, fixed it with masking tape from behind, and also put the door outer door in place too. Then I kneaded the steel putty, put it inside the door panel and closed the outer door panel over the internal one. The putty spread in the cavities between the door and body panels.

You see where I put the putty and how it cured. The critical region was done by the putty, and the remaining gaps I will fill with normal putty to flash the surfaces. Then I removed the Maskol from the body.

Dec. 28, 2003:

Forming the inside panel of the front door. I tailored a styrene sheet to fit in the left front door void and formed the bottom panel too.

I put the door in place and glued the outer and inner panels right there, to ensure a good fit.

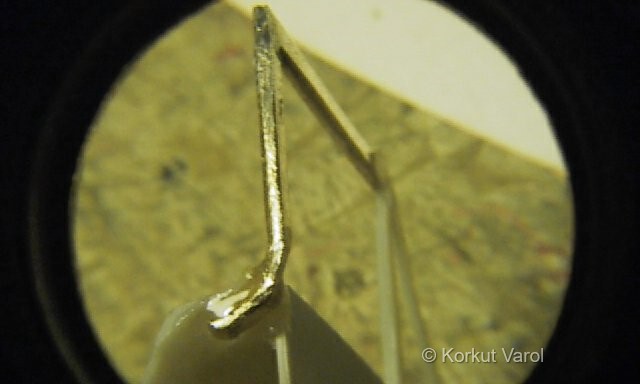

I cut the lock panel of the door, put a bent pin and fixed it with CA glue. You will see much more of the door lock on the next page.

I had to shave more plastic from the door panel to make a good fit of the brass and the plastic. I joined them with epoxy glue.

Here is the joined door.

......................

......................