01 February

2010:

I began

manufacturing the seats. I took

suitable pieces from my parts box. For the front seat, I used half

round

strips for the seat pattern. The photo shows the first one glued in

place.

I made the bottom part for the rear seat from styrene sheet.

02 February

2010:

I continued

the pattern for the front seat

and added a thickening part at its rear. I filled the bottom and back

sides

of the rear seat with polyester putty, and added a rounding part at the

very top. I began making the seat pattern the same way as the front

seats.

05 February

2010:

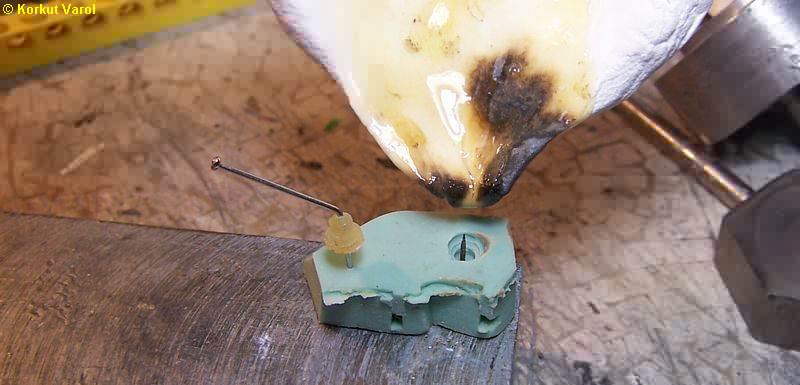

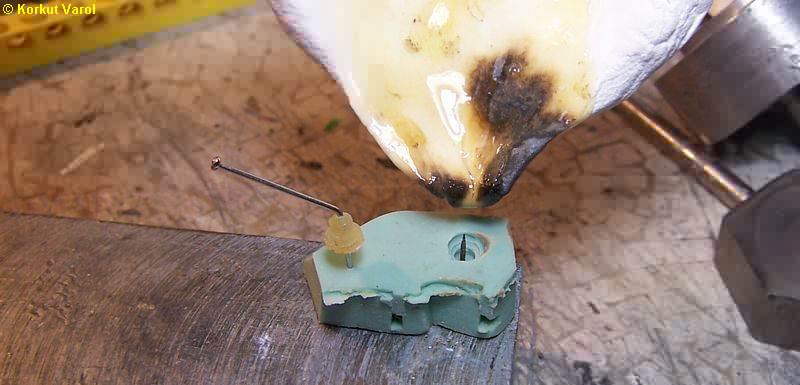

For the shift

lever boot, I made a mold.

I used a headed pin for the lever, and made the boot by melting E-Z

Water

(from Micro-Mark) in the mold. To provide easy entry for the pin, I

inserted

a pin from the backside of the mold so the boot would be cast with a

hole

inside. The lever and boot assembly is shown inserted to the left of

the

boot mold.

06 February

2010:

For the

steering wheel shaft and the signal

switch, I made a master from balsa and wires, then made a 2-piece mold.

For production, I located the wires in the mold, then applied marble

glue

at the center and closed the molds. The molded part is shown at the

very

right, nearby the master.

07 February

2010:

For the

steering wheel, I made a master

from wire and made a 2-piece silicone mold. In the middle photo, the

female

and male molds and the raw output is shown. At the rightmost is the

steering

wheel with rough cleaning of the flashings.

For

the front bumper, I shaped

an old cutter to the bumper profile and scraped a plastic strip over

and

over till I reached the normal profile.

Then

I shaped the bumper by heating,

sanded the ends, made the bumper horns from plastic and glued them on

the

bumper. I made the bumper brackets from wire and fixed them with CA

glue.

I will make a mold from this master.

25 February

2010:

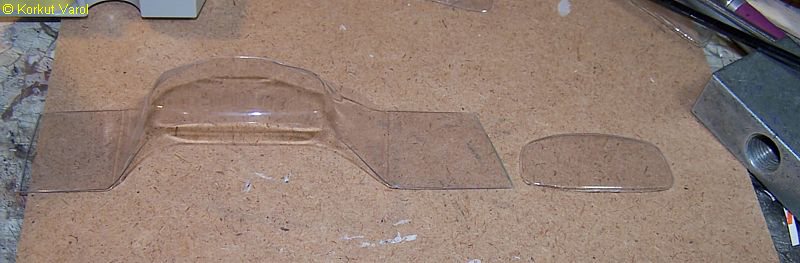

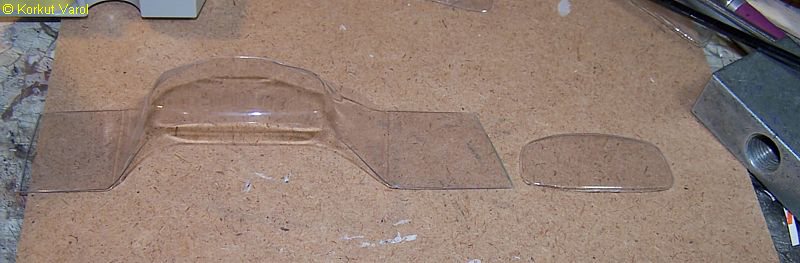

For the

windshield and rear glass parts

from acetate, I made a male mold from galvanized steel sheet and fixed

it on a Lego block. I held the acetate sheet between two frames and

heated

vith a heat gun. After softening, I pressed the assembly over the mold

and shaped the acetate sheet.

At

the left is the formed acetate

sheet, at the right is the trimmed part.

04 March

2010:

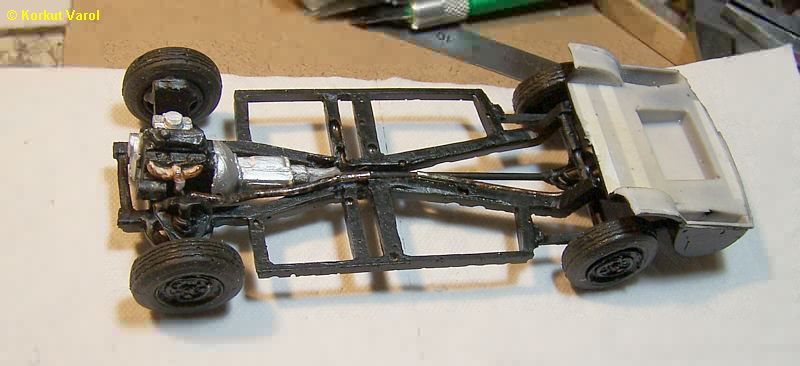

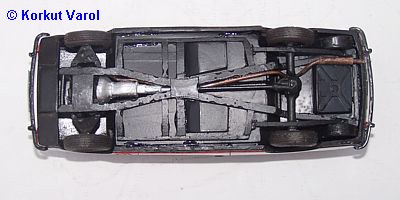

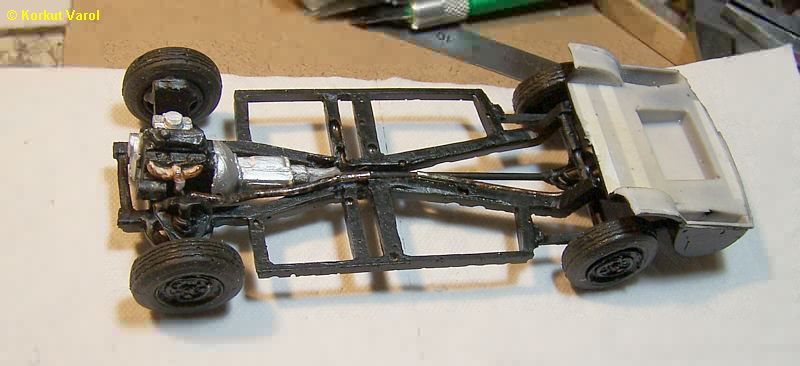

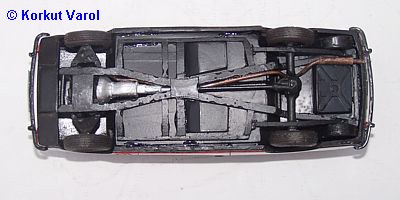

To check the

assembly steps, I began

to build the model of my Anadol that I once owned. The chassis is done

as below:

I

painted the body as by then.

I installed the inner side panels, the dashboard and the glasses.

A

look at the dashboard from outside

The

seats had covers made from

sheep hide. I used some dustcloth and covered the seats to depict the

original.

24 March

2010:

Photos of the

finished model. The red

band needs some retouch.

....................

....................

....................

....................