15 December

2005:

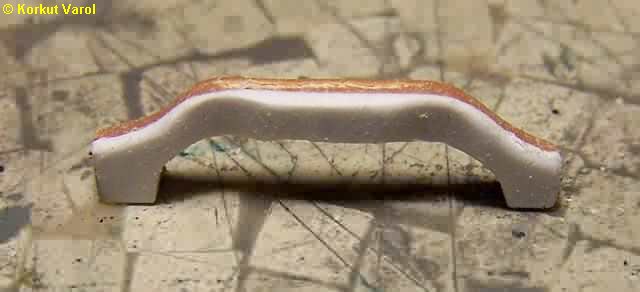

I cut the "top

covers of the U-profile chassis arms" from styrene sheet and glued in

place. |

|

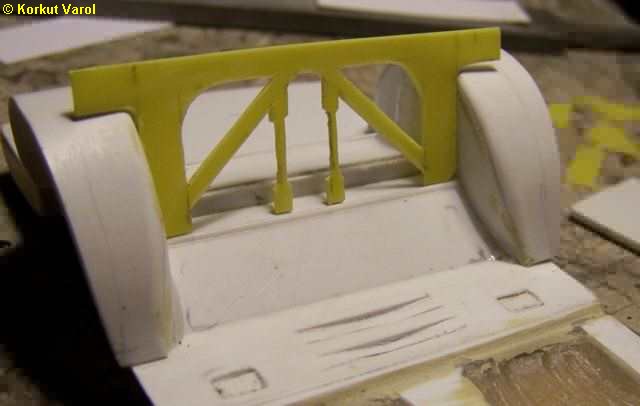

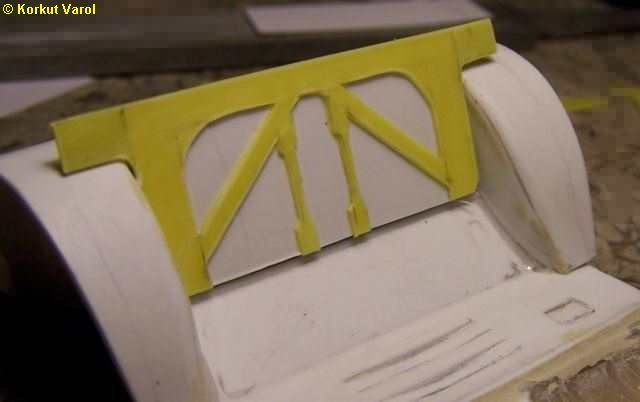

| I continued with

manufacturing the traverse behind the engine and above the gearbox. |

|

16 December

2005:

I manufactured

the front traverse and glued the front chassis assembly together. |

|

| I

cut the separating panel between

the passenger compartment and the boot. |

|

| Since

the boot should be separated

fully by a plate in real, I glued a plate to the back of the previous

panel.

However, the panel assembly are not glued in place yet. |

|

| I

cut and glued the inners of the rocker

panels. |

|

17 December

2005:

I manufactured

the lower front parts of the chassis arms from 3 mm square tubing

styrene,

and imitated the lower cover of the original U-profile steel by glueing

a styrene strip underneath. |

|

| A

mockup of the front chassis assembly. |

|

18 December

2005:

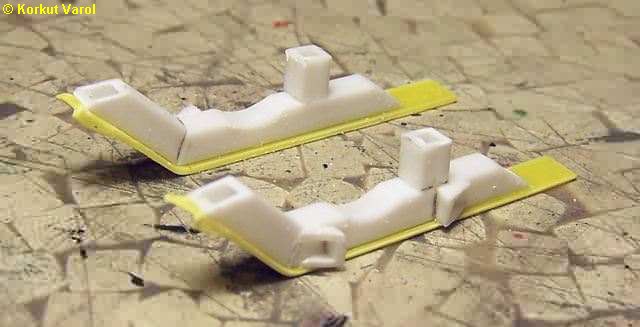

I constructed

the rear trailing arm and rear axle wishbone brackets. I also drilled

holes

in the floorpan and the front chassis arms, and inserted locator pins

in

the floorpan for correct positioning of the front chassis during

assembly. |

|

20 December

2005:

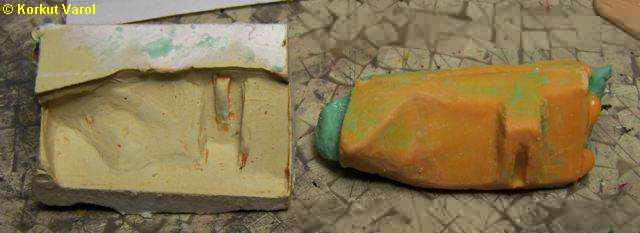

The engine bay

shape was a bit complex for sheet styrene working, so I decided to cast

the inner panels from resin. I began with the right side and first

carved

out a master block from a non-setting putty. |

|

| Next

I placed the block in a tailored

cardboard box to put the automotive polyester putty in. |

|

| After

curing of the automotive putty,

I took (or wiped) the master putty away to have the first hard female

mold. |

|

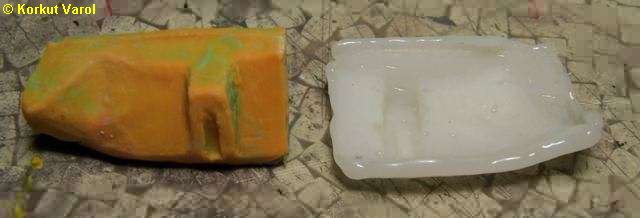

| Then

I made a silicon male mold from

the hard female. |

|

| But

to cast a resin part, both molds

should be flexible for releasing, so I made a second female by

injecting

plastic over the male from a glue gun. |

|

| And

here the first resin cast inner

panel is temporarily in place... I manufactured the left side in the

same

manner. |

|

25 December

2005:

I tailored the

full side panels from styrene sheet, engraving the door parting lines.

I gave a rough overall shape. |

|

27 December

2005:

I manufactured

the drip rails from 1.5 mm angle styrene profiles, tailoring the edges

to fit the body. |

|

| The

drip rail in place... |

|

|

|

|

|