|

(Selvi Boylum Al Yazmalim) |

|

|

Scale : 1/24

Started:

12 December 2007

Finished: 04 May 2016

Page 4 / 9

|

(Selvi Boylum Al Yazmalim) |

|

|

Scale : 1/24

Started:

12 December 2007

Finished: 04 May 2016

Page 4 / 9

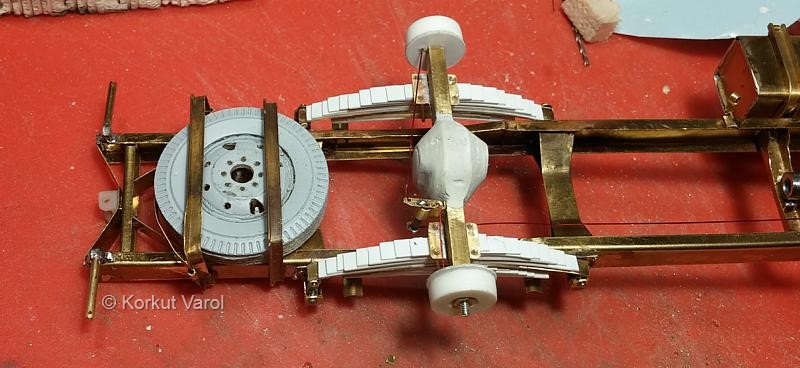

Manufacturing of the driveshaft. I cut the ends of brass tube with Dremel, then shaped with pliers to form the fork of the universal joint. I made the cross of the joint by solderinf two pieces of 0.8 mm wire. The leftmost part is to go into the differental housing. For the sliding toothed joint, I soldered a brass rod inside the tube.

The rear part of the shaft as assembled.

28 March 2016:

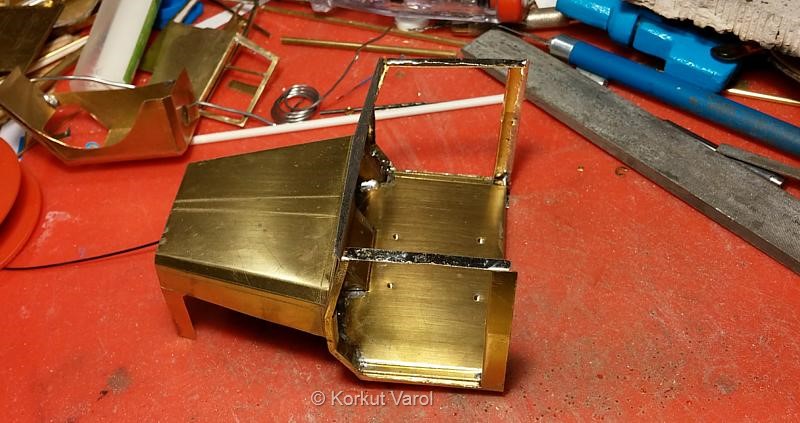

I

started to assemble the cab with the sides.

I fixed the hoses to the heater by CA glue, while held in place in the cab.

I made the bases for the seats from brass sheet and soldered in place.

I made the seating construction for the spare tire from brass.

....................

.................... ..................

..................