Build Period:

October 1996 - January 1997 | CAR BODY REPAIR SHOP |

|

.

Page 1 / 2

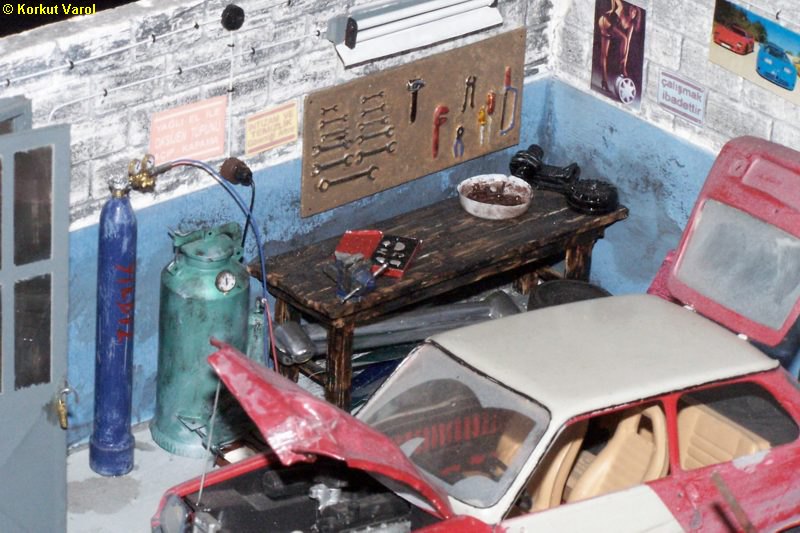

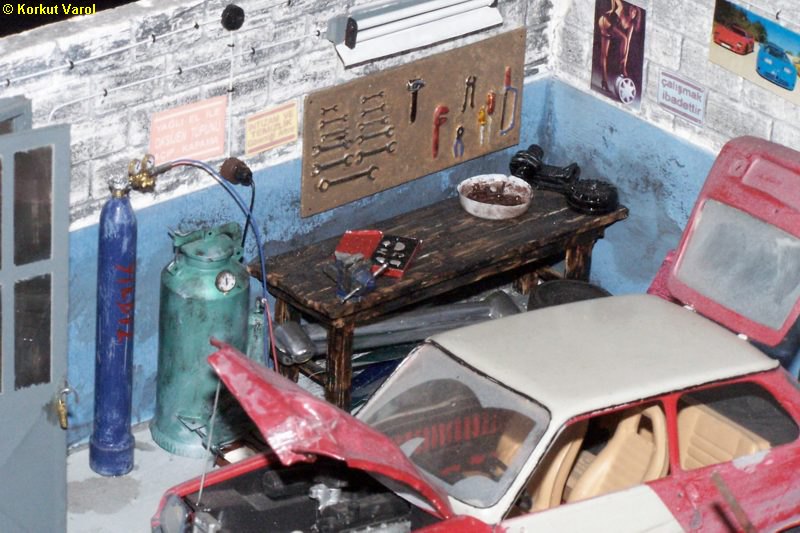

Now,

here is a typical car body

repair shop that you may see in Turkey. The shops are usually in a

mess;

you can rarely find a workshop that is neat , tidy and clean. In other

words, the workshops of authorized services are tidy and clean ; most

of

the rest look like this typical example that I built.

This

diorama uses only the

ESCI- 1/24 Renault 5 as a kit item ; in fact, the hood and the left

fender

are built of aluminium sheet and given a crushed form .

The

rest of the diorama is

scratchbuilt. While you go on viewing the pictures, you will see what

sort

of materials are used for construction .

.

The

oxygen tank is made of

aluminium tubing that was once serving as a TV antenna and the

acetylene

tank a casing for a cigar - (NO...I

Do Not Smoke!!!!). The pressure gauges are

carved from rubber

, so as the vise. ( My poor daughter couldn't find it in her

schoolbag

next day!)

The

walls are from 12 mm

thick gypsum boards and it was very easy to etch contours on it to give

it a briquette look. The hardest part was to scrape off the cardboard

lining

to reach the gypsum. The blue painted region on the walls are the

un-scraped

cardboards which gave an identical look with a plastered and painted

wall.

It is also a common practice to leave the higher parts of the walls

unplastered

and natural in those modest shops.

|

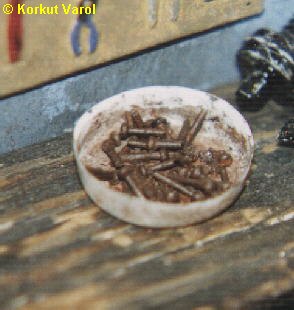

Here you see

the close-up views of the vise and the dirty plastic tray containing

rusty

bolts. The handle of the vise and the bolts are made of pins. The rusty

effect was given by first heating the pins on an open fire to a black

state

, then dry brushing . By the way, the tray is from the packing of a

medicine

pill. The workbench is from balsa, burned locally with the tip of a

soldering

iron to give the aged effect. |

|

.

Here

the master and his apprentice

are on their work to repair a damaged Renault 5 . The master is made of

a brass wire skeleton covered with a putty composed of flour,salt and

water.

The apprentice was once the Alaaddin of Disney Products holding the

magic

lamp in his hand. That figure was carved out to be what you see above.

What a fall

for him! I wonder if he remembers those good

old days when that torch was the magic lamp...

By

the way, I hereby strongly

protest all the

manufacturers for producing so many 1/35 figures and so few 1/24

figures.

Do we have to compose all of our dioramas on military basis?

Those

dirts caused by spilled

oils in real life are caused by the same thing over here - drops of oil

from my car's oil sump. No paint would look more real.

This

FIAT 131 has had a big

impact at the front , so brand new front panels are being assembled on

it. The crash had also an effect on the right B-post, so it is forced

back

in place by the aid of a screw jack with wooden blocks on both ends in

order not to over-stress the metal.The roof has also been removed due

to

the deformation caused by the B-post displacement (which you will see

it

is thrown outside the shop in the oncoming pics.)

This

item is made of 0.20

mm thick brass sheet metal. In general, solder is used to join the

parts;

however, when solder is precluded to leave unmachinable residue around

the joint, then cyanoacrylate joining is used.

| Here you see a closer view

of the B-post. This item is manufactured by casting lead and machining.

It is then soldered into place and joints are remachined for a good fit. |

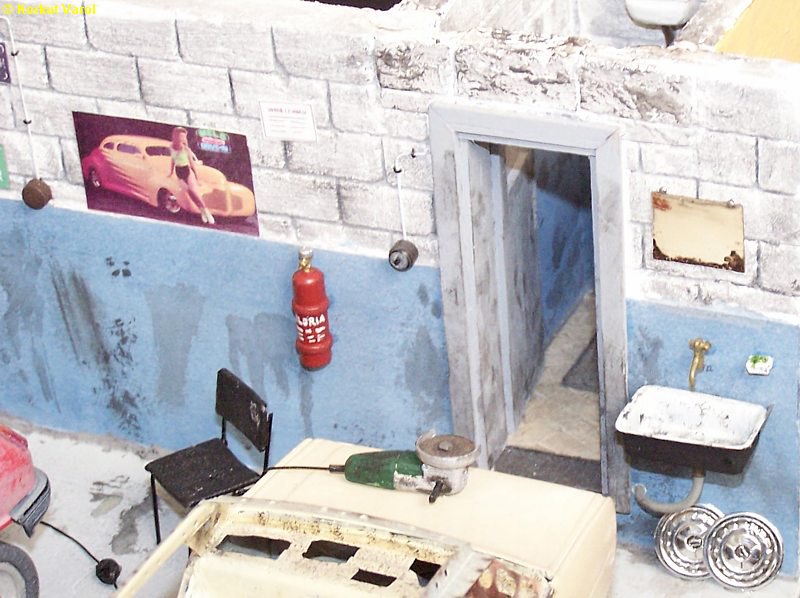

This

close-up shows details

on the back wall of the shop. The poster is reduced to 1/24 scale on a

color copier . The electric switch near the toilet door is carved out

of

a BC-108 transistor. The tap is out of brass wire joined with solder

and

machined. The washbasin is made of 0.2 mm sheet brass, having

considerable

filling with solder and as much machining.

The

grinder body is of balsa

block, the shield of 0.2mm sheet brass and the disc being a worn-out

remainder

of the Dremel! That means it still works after it has finished its

duty!..

Now

you see a better view

of the workbench, the oxy-acetylene welding set, the tool-hanger plate

on the wall. The tools are embossed on a 0.2mm aluminium sheet (that is

the hanger plate) and painted to give the realistic impression. The

doors

are cut from acetate sheet, formed, given a peripheral profile with

balsa

bars and painted. Though not clear in the pic, the "glasses" are broken

occasionally and given a tint to duplicate the never-cleaned glasses of

such a workshop.

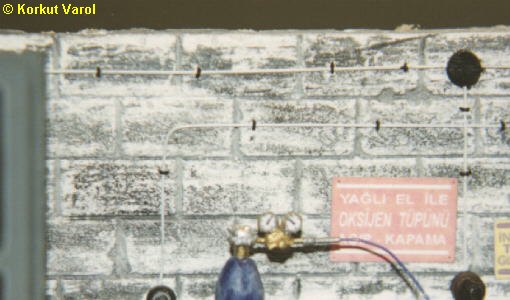

| This photo shows the wiring

detail on the walls. The cables are copper wires painted white, and

they

are held on the walls by the U-shaped pins painted black that are

inserted

in the walls.

That writing is a reminder

telling not to open or close the oxygen valve with oily hands. |

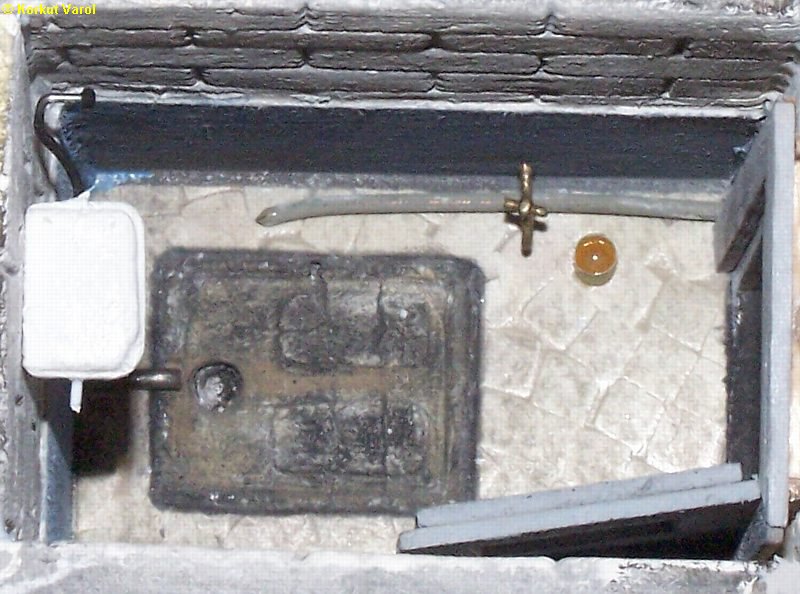

This

is the view of the WC

from above. In Turkey, the toilets are mostly the a

la Turca

type - that is, you do not sit on the closet but simply crouch. This

type

is claimed to be more hygienic for public places since your body has no

physical contact with the environment. That might be true - if only

people

cared about cleanness! This thing here is not manufactured from ceramic

clay, instead, it is cast from mosaic concrete. This yields a cheaper

product

that ends up with extensive use in such places. Its aged effect is

given

by dry brushing mustard tone over the blackened stone. The discharge of

the wash-basin goes through a plastic hose towards near the hole of the

toilet (Minimization of plumbing!). On the left wall protrudes the

water

tap with a tin can beside it; together which serve for cleaning

oneself.

Sorry - no tissue papers can be met!!

You don't use underwear made

of non-absorbing material, do you???

Why

build walls and leave

them empty? Three posters of a famous Turkish folk singer have been

pasted

on the wall - however, updating service does not seem to be dynamic

enough

since the posters have faded and torn... These posters were also scaled

down with a color copier and sanded very fine while resting on a smooth

and irregular surface.

The

ground around is real

ground , stuck in place with the common white furniture glue.Moist

effects

are made by airbrushing gloss lacquer. The roof of the FIAT 131 inside

is leaning against the wall with the hood of a Volvo 850. Both are made

of aluminium sheets. The thrown-away Castrol GTX oil cans are made of

paper.

|

|

|

|

|