|

|

|

|

.

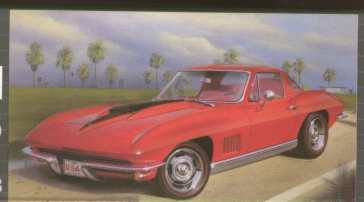

| The model in question is a 1/24 Revell 1967 Corvette Coupé . I decided to convert it to a convertible. I began to make it because I thought that there did not exist any such model until I got the news from my friend Al Superczynski (R.I.P.) that there actually did. Anyhow, some work had already been started so it had to be finished. |

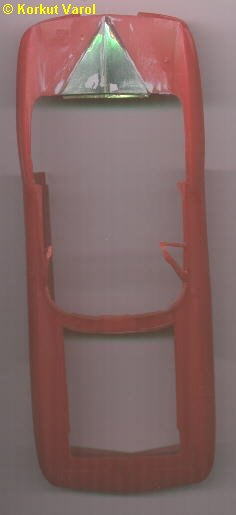

| I

cut the roof and opened the boot lid area. I manufactured a tin piece

to

cover the triangular hole left after the boot lid, and fixed into place

with epoxy adhesive. The irregularities at the matching edges were

sanded.

I also made the boot lid from tin.

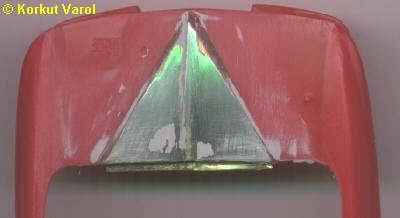

The following are two photos about how the backside looks like. |

|

|

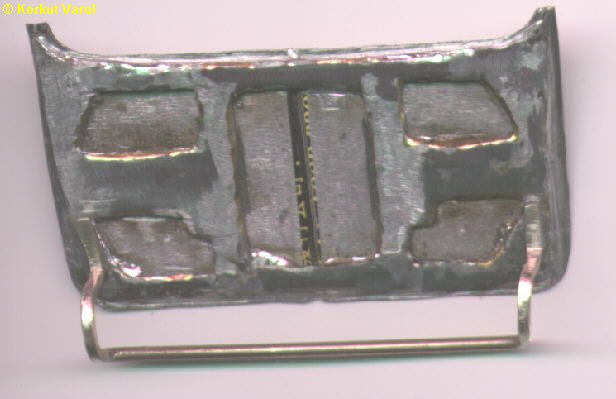

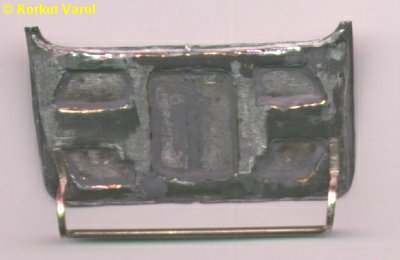

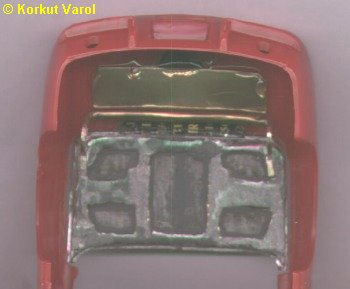

| Below are the pics of the bootlid. The inside of the bootlid has the reinforcement also made of tin and soldered into place, then grinded to smooth shape to match reality. The edges where the reinforcement meets the lid are then lined with putty to close the gaps. |

|

|

|

|

|

|

|

|

|

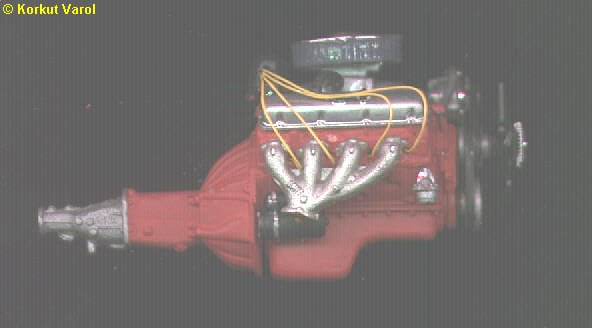

Now is the turn of the engine.

The stock engine was used, but with the addition of PCV hoses and spark

plug cables.

|

|

|

|

|

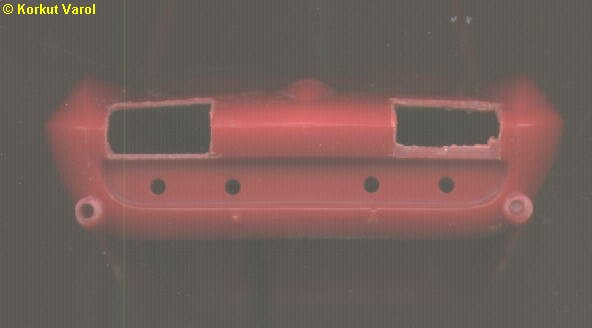

The thickness of the plastic body is too much as seen on the left headlamp recess, so it was filed down to 0.5mm so that it could be as close to scale and yet firm enough not to break. The filed down recess is on the right side as you see in the picture.

|

|

| My,my,my--- A primer coat

at last!

It was really nice to see so few points to take care of. It ended up better than I expected, so I served myself some whisky upon drying of the primer coat. |

|

| The sides of the headlight recesses are no good like this. The gaps should be closed by some means and seem full when viewed at an angle with the headlamps. |

|

| The side profiles were cut from plastic sheet and glued, and then smoothed with putty and sanded for a flush fit with the recess edges. Fine sanding took care of the unwanted residues due to moulding as well. |

|

|

. |

|

| The dashboard is painted red ( 1:1 mixture of Humbrol 60 and Humbrol 19 to give a satin effect ) and satin black (Hýmbrol 85) , the glovebox lid Aluminium (Humbrol 56) and the switches, radio, gauge bezels and emblem on the glovebox lid Silver ( Humbrol 11). The gauges are done with application of the stickers |

|

|

|

|

| And now the headlamps. First, the bezels and headlamp housings are cut from thin sheet brass. Then the housings are bent to suit body profile(1st picture). The reflectors are prepared from aluminium sheet (2nd picture). The rounded tip of a wooden rod is used to press the aluminium inside the female part, still made from wood. Next, the bezels are thickened with solder(3rd picture) , filed to required thickness with hand, and countersinked with a proper tip of Dremel moto-tool (4th picture). Then the whole are assembled with 5-minute epoxy and painted (last picture). The lenses came from my parts box. |

|

|

|

|

|

|

|

|