| The

pics have to start not from the

very beginning. I had already taken some way along when I remembered

that

I had a camera...I decided to use the inner roof for the roof. I cut a

mating piece of styrene for the gap in the middle of the panel. The

front

part of the roof was cut off, and a styrene piece was tailored for the

front of the roof. For the roof reinforcements, strips of styrene were

cut and glued at their ends. That catches up with the pic!!! |

|

| The

strips were glued on the roof and

held in place by rubber bands. |

|

| Only

the driver's seat was used from

the kit. The rest of the seats were built by glueing layers of sheet

styrene,

and sanding them smooth. |

|

| The

legs for the rightmost seat of

the middle row was made from paper clip wire. |

|

| The

roof was traeted with polyester

putty |

|

| ....and

sanded smooth as how it should

be. |

|

| The

cloth pattern was created on the

computer and printed on a sheet of paper. But how I came to this point?

My first trials for duplicating the pattern was painting the seats flat

white and drawing the pattern with a felt tip pen. I definitely did not

like (which means did not succeed) the job. Then I tried to cover the

seats

with paper, and seeing that it would be OK, I drew the pattern on the

computer.

It took some trial and error time to match the real tones. |

|

| Here's

the driver's seat covered with

printed paper. |

|

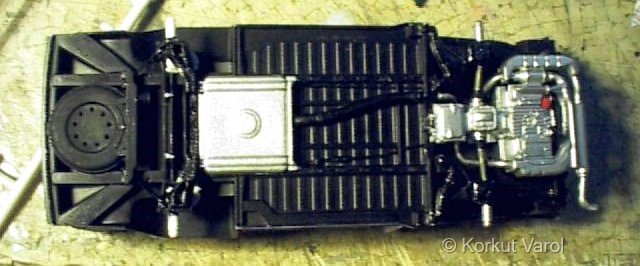

| The

bottom was just done and painted

as per box-stock instructions. |

|

| The

seats looked like a garden bench,

so I thought of a way to make them look like real seats. I folded

tissue

paper for cushion effect and made a try to cover it with the printed

pattern

paper.... |

|

| .....and

VOILA!!!!!! Liked the

looks and went on. |

|

| This

is the first seat completed that

looks like a seat. |

|

| Unfortunate

for duplicating was the

rims. The real vehicle had no chromed covers; but the kit's rims had

them

molded as one piece, so I had no chances of manufacturing the rims

without

the caps (at least for the time ahead) so I covered the caps with Bare

Metal Foil and painted the rims aluminum as in the real case. |

|

| The

rolling chassis. |

|

| I

installed the seats in place. They

look good now... |

|

| Another

view of the mid and rear seats. |

|

| I

painted the body white first, then

masked and painted the yellow tone. |

|

| The

internal roof lining was tailored

from styrene sheet. I overlooked the fact that it was looking flat

white;

but I would regret it after installation, when I saw that the sheet was

reflecting images! |

|

| I

drilled a hole for the radio antenna

and fixed an aluminum piece of wire with CA glue. |

|

| Now

a bit detailing...The front grille

emblem was treated with Bare Metal Foil, and the mirrors were given a

BMF

treatment, then painted flat black. |

.. ..

|

| On

the roof lining, I drilled holes

for hanging cables for dome lights. I imitated the cables as per the

real

case and glued them in place with CA glue. |

|

| I

put BMF under the rear lamp lenses

and then fixed them in place. The BMF really makes a difference in the

looks of the lenses. |

|

| Now

for the "wide-angle mirror inserts"

on the rear view mirrors. I covered the end of a styrene rod with BMF

and

painted the circumference flat black, as in the first pic. Then I cut

the

rod at an angle and glued the final part on the mirror with Testors

window

maker. |

|

|

|