It all began while

surfing in the site of CARS-Chattanooga

Auto

Replicas

in Scale. There

was an on-line contest about Tamiya's VW New Beetle. It immediately

came

to my mind to make a stock car racer out of it. It would definitely be

a demanding task. However, the deadline was 31st of December and the

date

I knew about the contest was the third week of November. I immediately

ordered two kits- Tamiya's New Beetle and Monogram's #99 Ford Taurus.

The

chassis and mechanics of the Taurus were to be adapted and put under

the

bug's shell. But by then, I knew almost nothing about Stock car racing.

So I also ordered "Building and Detailing Stock Cars" from Kalmbach,

and

also detailing items from Detail Master and Slixx Decals. It was the

end

of the first week of December when the kits arrived, so I had three

weeks

left. Fortunately, the book had arrived earlier and I had time to read

all about stock car races and regulations, and keep on surfing about

NASCAR.

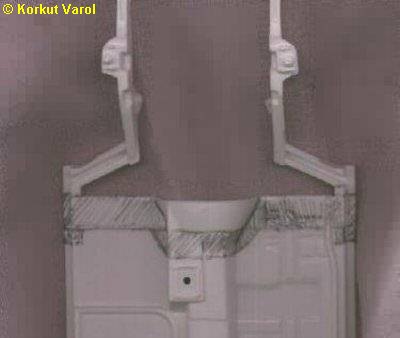

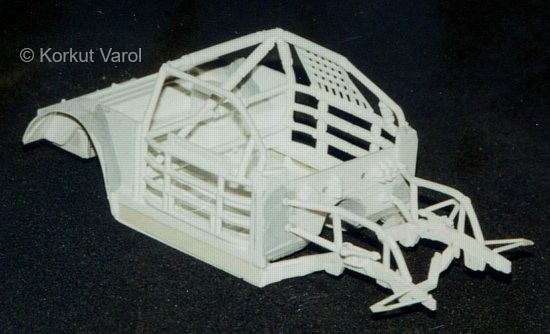

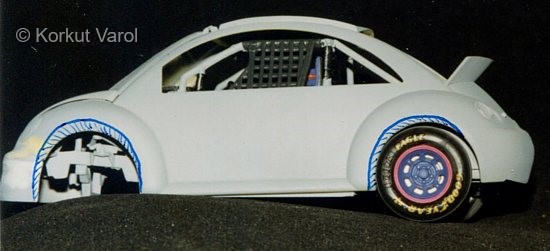

The

first measurements

showed that the widths of the cars were suitable, but the Taurus

wheelbase

was 10 mm longer and it had to be cut as shown at right. Extensive

cutting

and shaping would follow. |

.

|

|

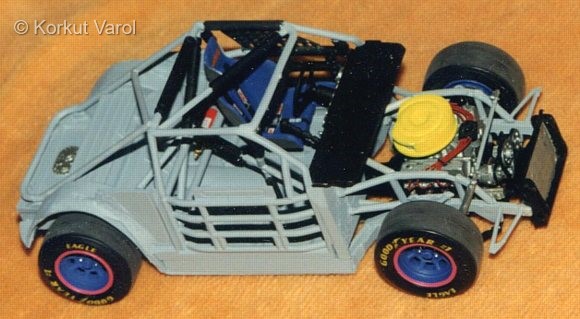

As usual, the engine

was constructed first. For better details, the spark plug wires that

came

moulded with the distributor were cut and replaced by copper wires and

painted red. The pulleys were drilled at their holes for better

appearance.

|

|

|

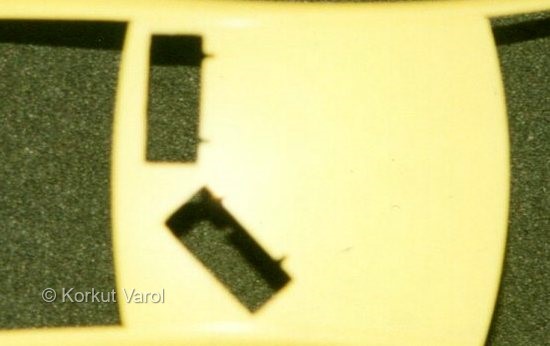

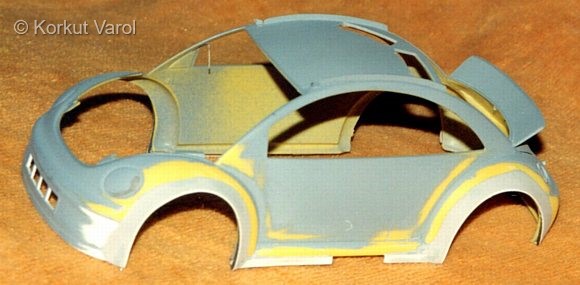

On the body

shell, roof flaps were drawn and cut out. New flaps were made from

brass

sheet and hand-filed to fine fit their places.

(Right

and below)

|

|

|

|

|

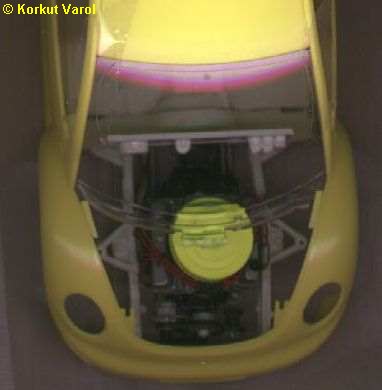

Test assembly showed

that the engine would be too much backwards that it would almost

completely

be under the dashboard, so it was re-located to the front as much as

possible.

The picture at right shows the new position but still, maintenance

would

be a big problem since the air filter was partially beneath the

windshield.

So a radical solution to make the car with a "hatch-front" was made.

The

engine hood would open together with the windshield to provide easy

access

to the engine compartment.

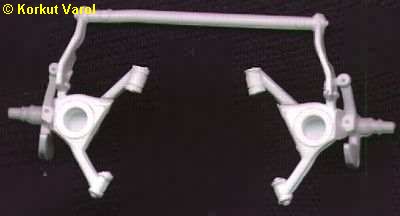

Shifting

the engine

to the front also required the lower wishbones have their front mounts

shifted, so they were cut and front parts elongated with scratchbuilt

parts.

|

.

|

|

The recess under

the bumper was cut for completing to a front spoiler at first; but

seeing

that the Taurus front spoiler fitted almost perfectly, the front bumper

was cut off at the marked line and Taurus spoiler glued to the beetle.

Then came of course filling with putty.

(Below

and right)

|

|

|

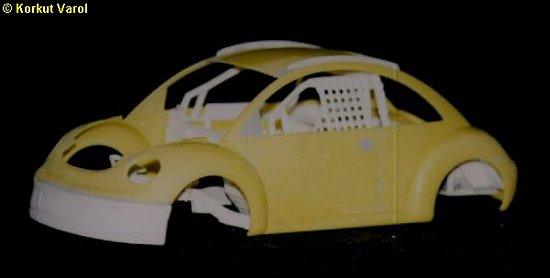

| Test-fitting the

shell and the chassis showed that the roll-cage was too low, so was the

driver's level. The side bars and so the driver's seat was lifted by

6mm.

and levels became all right. ( Right and below ) |

|

|

|

|

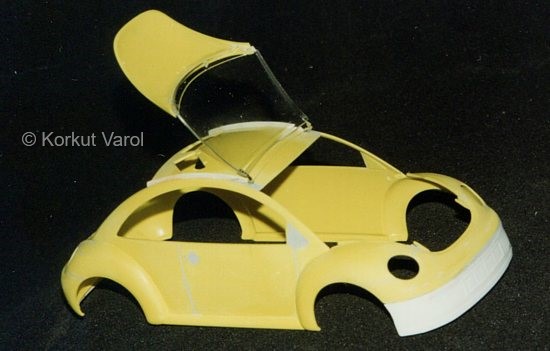

| Now was the turn

of the hatch-front assembly. First, roof rails were cut from sheet

styrene

and glued into the recesses made along the roof. Then, the hinges from

Detail Master were glued with CA glue to the roof and to the

windshield.

The hinges were put together temporarily and the hood glued to the

windshield

with Bison 5-minute epoxy glue after trimming the bottom of the

windshield

to fit to the hood. ( It had been displaced to the front by 2 mm being

mounted externally.) |

|

|

| At the back, recesses

for the VW-emblem, license plate and the bottom of the rear bumper were

filled with styrene sheets, putty applied and sanded smooth. A hole for

the fuel filler cap was drilled on the left fender, using the recess

for

rear lamps. |

|

|

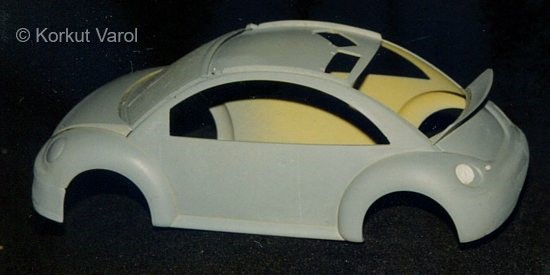

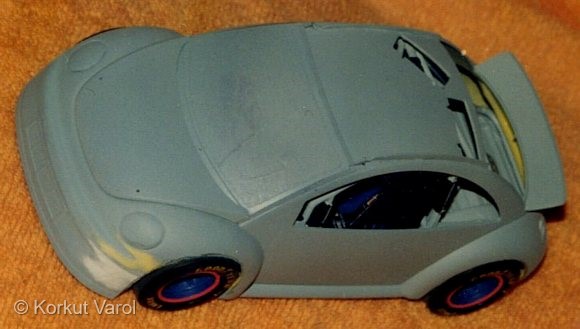

| A rear spoiler

wing was cut from sheet styrene and glued at the bottom of the rear

window

gap. The first primer paint was applied and the fuel cap and overflow

pipe

cut from the Taurus glued into place. |

|

|

| Test-fitting the

body, chassis and wheels defined the contour where the wheelarches had

to be cut. |

|

|

| Meanwhile,

the chassis was prepared. Since the rear overhang of the Taurus was

larger

than the Beetle, the profile between the wheel housings was cut off and

the fuel cell located as displaced towards the front so as not to

interfere

with the rear axle. The fuel cell was made from scratch styrene sheet

and

the Taurus fuel cell top was used as its top. |

|

|

| The kicker bar assembly

was also altered due to shortening at the rear and things began to come

out more physically. |

|

|

| This is the bottom

side as finished. The exhaust pipes had to be cut and bending angles

changed

due to the shortening of the wheelbase. The driveshaft was also

shortened. |

|

|

| The wheels stood

a bit outside the fenders, so small styrene slabs were cut and glued to

the fenders and as a skirt to get closer to the ground. Then the joined

edges were filled with automotive polyester putty and sanded to smooth.

( Right and below ) |

|

|

|

|

| Then the rear and

front axles were glued into place and wheels added on. Before that, the

tires were sanded to give the look like they had taken a few tours

around

the track. |

|

|

| |

|

|

|

|

|

|