29 October

2005:

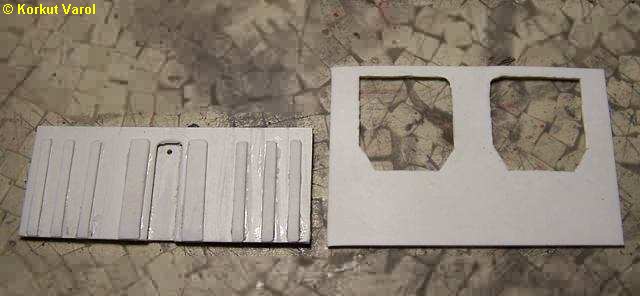

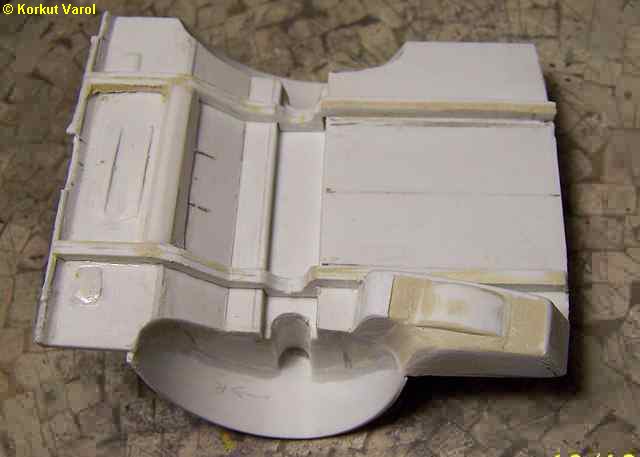

After making

enough sketches and drawings, I began with the front and central parts

of the floorpan. |

|

05 November

2005:

I continued with

the rough construction of the floorpan. |

|

06 - 22 November

2005:

I experimented

on various materials for the bodywork construction. From copper as a

whole

and separate panels, from tin sheet, etc. I decided that plastic may

work

out better with this scale. |

|

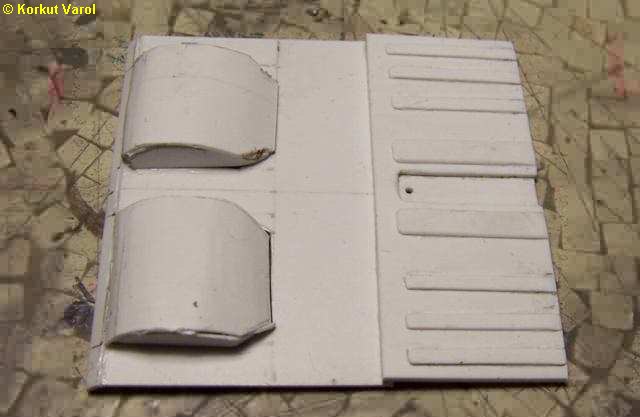

26 November

2005:

Continued with

the rear parts of the floorpan, the boot platform and the gas tank

shield. |

|

28 November

2005:

I detailed the

gas tank shield and manufactured the rear chassis arms. |

|

| Now

the bottom of the floorpan is beginning

to take some shape. |

|

29 November

2005:

I manufactured

the inner sides of the rear wheelwell and shock absoerber housings. |

|

| After

curing, I cut open the sides

to reveal the shock absorber housings. |

|

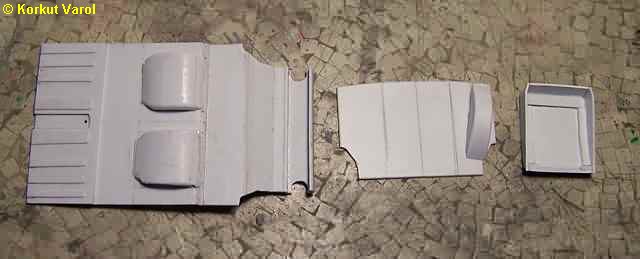

03 December

2005:

I was dealing

with the deatiling of the bottom of the floorpan and leaving the top

(inside)

blank, but then I remembered that what I was building was a rally car

and

that the floorpan was bare metal! So the stampings had to be seen at

the

inside too!

Next move was

to disassemble the glued floorpan....

Then I imitated

the internal stampings by pressing the tip of a heated file on the

plastic.

|

|

| Filing

and sanding clean, the stampings

exist at the inside too. |

|

06 December

2005:

But the rear

"pans" in the floorpan coulsd not be made by any heated tips or so, due

to the curved surfaces. So first of all, I made a female mold from the

plastic I had manufactured. |

|

| I

cast a full resin male in the silicon

mold. |

|

| Then

I pressed a 0.2 mm thick aluminium

foil over the male, to make a "pressed steel panel duplicate"... |

|

| I

prepared a second female and another

male around this metal part, so that the male and female molds had a

sheet

clearance between them. Then finally, I cast a thin resin part to go in

the recess in the floorpan. |

|

10 December

2005:

I corrected the

spare wheel storage space, made the stampings in the rear seat area and

applied some putty here and there. |

|

13 December

2005:

I had glued the

resin pans in before, now I applied putty around them for smooth

transition. |

|

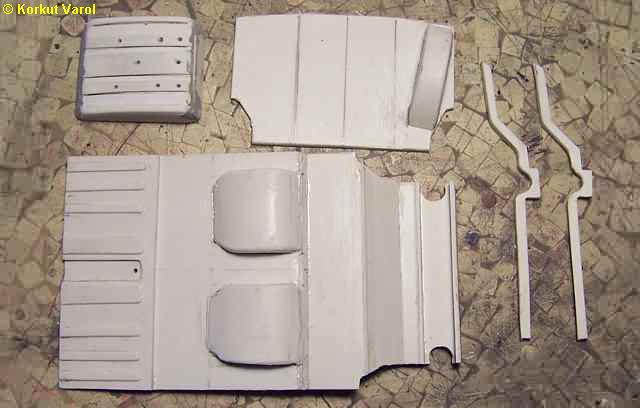

13 December

2005:

I started manufacturing

the front chassis arms. To scale the true width, two strips of 1.5 mm

thick

styrene per side was cut. |

|

| Then

I joined them in pairs as in the

photo. |

|

|

|

|

|