| Now to the steering links. The items

shown

here are the bellcrank to transfer the fore-and-aft motion of

the

rod from the steering box to right and left, pushing the track rods.

The

item on the right is the pivoting bracket of the bellcrank mechanism.

All

are made from 0.2 mm brass sheet. Note the four pop-ups made by

hammering

a point that resemble bolt heads when painted. |

|

| A pin is soldered to the bellcrank.

Its

length is cut so that the pivoting bracket will just fit in. |

|

| The two are assembled on the chassis

with

glueing the bracket on the chassis, taking care that no glue touches

the

pin, so that it will rotate freely. |

|

| Back to the body. Srips from styrene

sheet

are cut and given oval profile at the ends and glued with CA glue under

the floor panels. These represent the reinforcing stampings on the

panel. |

|

| The rear axle is united with the

brake

discs taken from the New Beetle. The wheel retainers are put in the

hubs

before assembling with 5-minute epoxy. |

|

| The body and chassis are painted at

last.

Clear amber glass paint was airbrushed for 5 coats. |

|

| The rear axle assembly is put on the

chassis,

with pins cut to proper length in the spring eyes and fastened with CA

glue to prevent slipping off. |

|

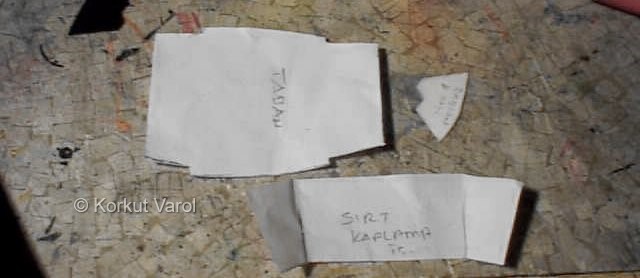

| Templates for trim elements are

traced

on to paper from the body itself. |

|

| The floor and side kick panels are

covered

with self-adhesive black velvet sheet, cut in accordance with the

templates. |

|

|

|