14 July 2012:

To

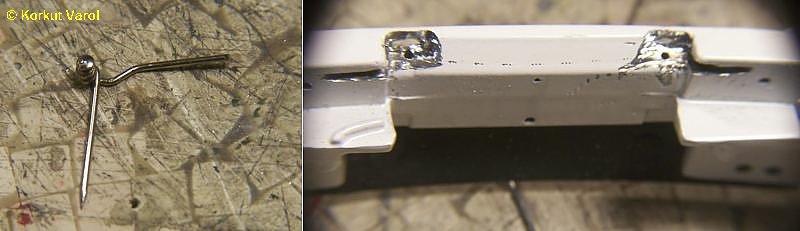

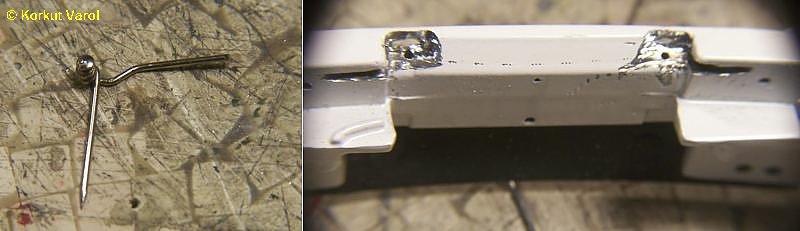

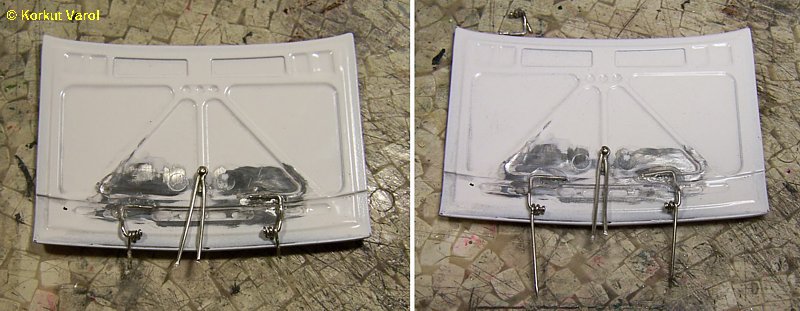

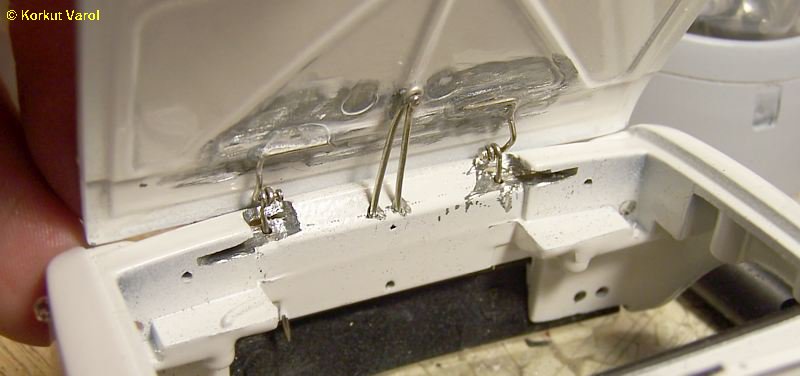

open the hood correctly, I needed to place the hinges as close to real

as possible. I carved the points with Dremel, made hinges from headed

pins. I drilled 0.8 mm holes to place the hinge support pins.

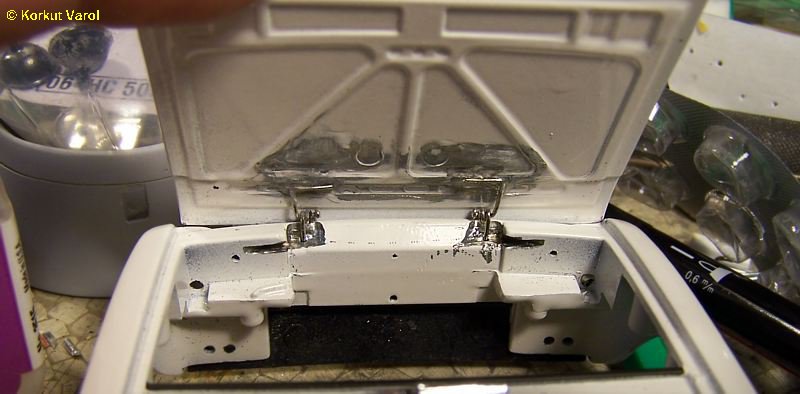

I fixed one end of

the hinges to the hood with CA, inserted the other end in the body for

operational check. Due to material thickness, the hood touches the body

just before fully open position and keeping on, lifts the hinges about

1-2 mm. The remedy was to cut all the area there and make new

scratchbuilt construction; but I decided it was not worth the efforts.

I made the knob to hold the hood support from headed pin. I carved the hood with Dremel to hide the pin body.

15 July 2012:

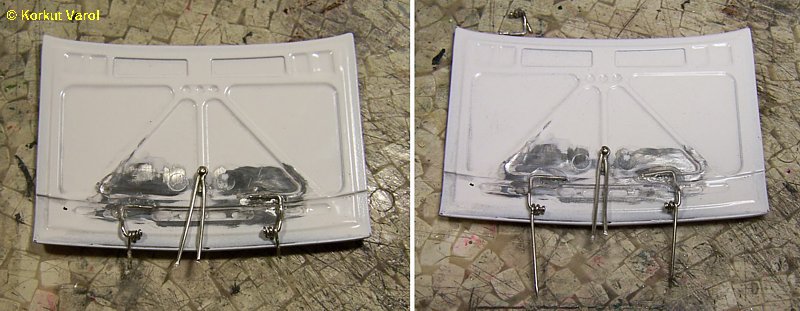

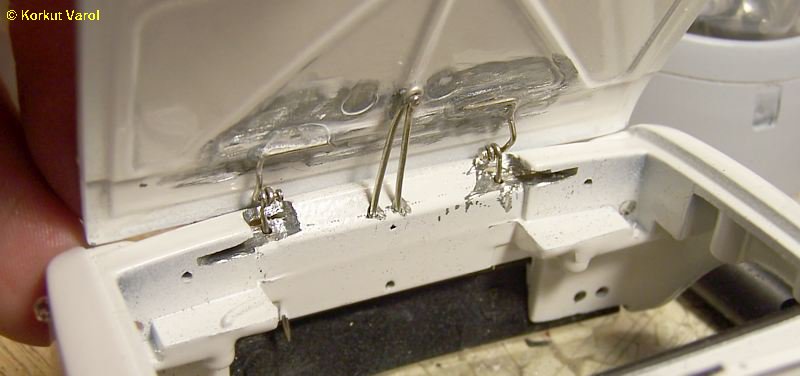

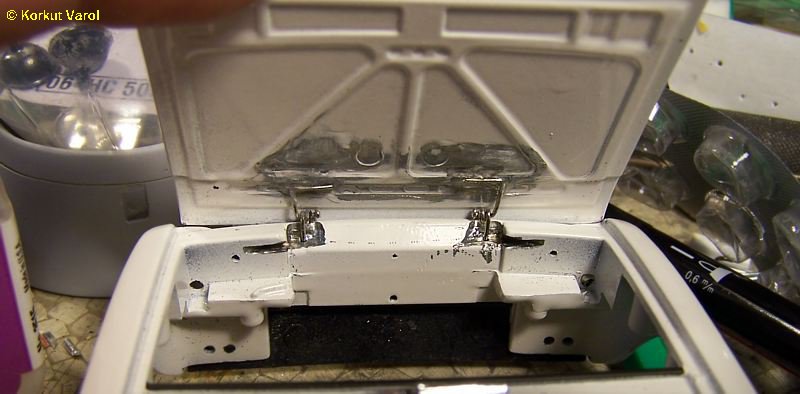

I

made the hood support and made another operational test which showed

that the hinge arms located inside the body were too short. I made new

longer ones and installed in place.

I drilled holes for the hood support and made the final operational check.

I painted the white places visible between the front and rear window strips and the body to flat black.

The inside before the change. The real car was black inside.

I started with the rear doors, painted satin black and applied Bare Metal Foil to the door insides and safety belt.

I applied Bare Metal Foil to the strips which were aluminum on the model. The visual difference is obvious.

18 July 2012:

Time

to cover the seats. In previous models, I had printed the seat pattern

on paper and glued over the seats. This time, I wanted to try a new

approach. I used a paper napkin for imitating fabric texture.

I cut a piece of napkin and fixed on an A4 paper with masking tapes. I

prepared a texture pattern on the computer and printed with laser

printer. I took the napkin off the paper and separated the napkin

layers. This gave a translucent textured cover (seen under the seats in

the below photo).

I applied grey primer to seats. I cut sections to cover various seat

regions and glued with spray adhesive after waiting for 20 minutes. The

union of paper and adhesive results in a partly flexible surface that

does not readily get torn when stretched. This enabled to stick

smoothly to curved surfaces.

The seat grooves become apparent when pressed by finger, smoothly pressing with a toothpick gave a full groove duplication.

Front seat covered.

A visual check with the seats covered.

A close-up of the surface texture.

I

prepared the floor mats on the computer. In those years, a popular mat

make was Durulax, I drew the design as much as I remembered. I applied

aluminum duct tape on the back side to prevent oozing of the glue. Then

I applied flat clear on the floor mats.

After applying black flocking on the floor, I glued the floor mats in place.

21 July 2012:

I made the small center console from plastic sheets and fixed in place.

22 July 2012:

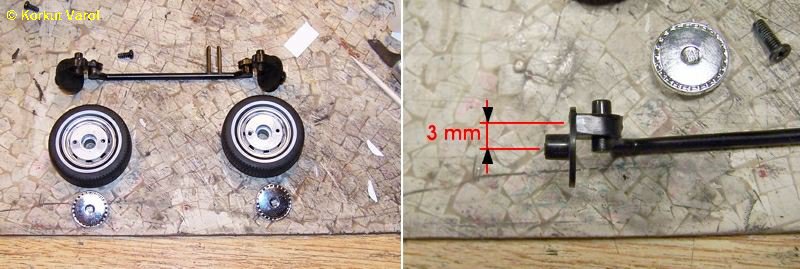

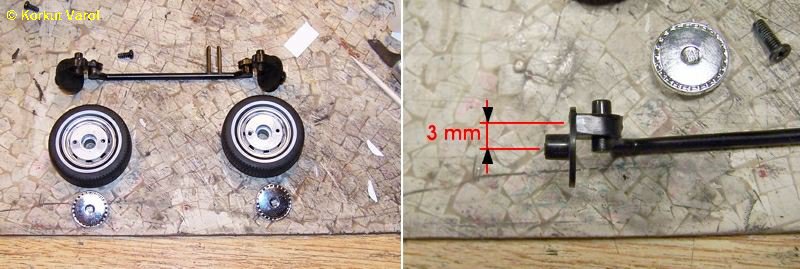

Time for lowering the front... I

disassembled the front members. The front end had to be lowered by 3

mm. The only place allowing play was the tie rod connection point.

I

cut the arm and disc connecion with Dremel. This arm needed to be glued

to the disc axis but only glueing would not be sufficient. So I drilled

a hole at the center of the arm base. The screw holding the wheel will

go through this hole as well, to make an additional mechanical joint.

The original screw of the model was short for this, so I used a longer

screw.

Mission completed.

Now

the height problem was over, I went on to the front track width

problem. It was 4 mm wider at each side, which was done by cutting 2 mm

at the wheel and 2 mm at the disc centers.

Then I reassembled the model. Finished photos are on the following page...

.........

......... ........

........

....................................

....................................

....................................

....................................

.........

......... ........

........