The

model of the Ford Transit public transport minibus that appeared in the

Turkish film "Çiçek Abbas" (1982).

The

kit I used is the facelift of Transit Mk.2; moreover, it is a van and

not a minibus, so a great deal of modifications will have to be made.

The kit is a reissue of the old ESCI kit, and I had to wait till it was

available.

|

|

22 October

2016:

While

waiting for the kit, I began exercising with the manufacturing of

various accessories that will consume time in the future. I made a

balloon from wood and took mold of silicone.

|

I

cast parts from various materials like hot melt glue, EZ-water, 100

layers varnish. The best outcome was from hot melt glue. I

dipped

the balloon in clear glass paint and after drying, I drew stripes and

covered the whole with stretched parafilm.

|

23 October

2016:

Exercise

for the flowers around the roof luggage carrier. I drilled a cavity

within a silicone piece, naturally an irregular one depending on the

tearing of the silicone. Then I injected hot melt glue in the cavity

and before cooling, I pressed a piece of thread to fix the flower on.

|

I tried with string and wire, and

painted to see better what it is like. It looks like flowers I think...

|

29 October

2016:

For

the pompom lining inside the windshield, I found something like this. I

took off the horizontal fibres, then cut off one at each second

vertical to reduce the fibre numbers.

|

30 October

2016:

I

used a piece of masking tape as a spacer and inserted the fibres

through beads, fixed them with CA glue and trimmed the excess fibres.

Then I applied pink flocking all over and got the pompom line.

|

14 November

2016:

At

last the model arrived. To convert the van to a minibus, first I marked

the windows and cut them open. I shaved the left rear door handle.

|

The back door would be 2-piece,

so I shaved off the hinges and the bottom side lock.

|

16 November

2016:

I glued the central

uprights and scribed a parting line on the back door. I cut off the

right rear door.

|

|

17 November

2016:

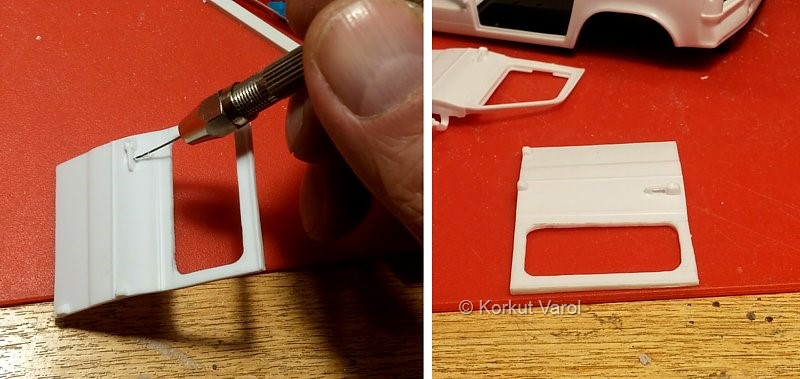

I

drilled the door handle and later sanded the grabbing void on the

handle.

|

|

19 November

2016:

I

prepared the internal frames to hold the glass parts. I rounded the

edges with a radiused blade I shaped for the purpose.

|

I made radiused parts for the

back door central uprights.

|

|

20 November

2016:

I shaved off a layer to house

the inserted acetate sheet as the glass.

|

Manufacturing

of the hinging for the rear door.

I

made a cut in the hinge bodies on the door. I prepared the hinge ends

from brass sheet, bent and inserted in the cuts then fixed with epoxy

glue. To maintain concentricity, I used a headed pin as the axis.

|

|

I

prepared the mating parts of the hinge on the B-post from

styrene and glued them on the B-post while holding the door in

place.

|

|

I applied

pressure on the hinges while curing.

|

|

Checking the

operation of the door.

|

|

21 November

2016:

There

was a gap over the back doors. To cover it, I glued a piece of styrene

strip.

|

|

22 November

2016:

Then

I applied polyester putty and sanded.

|

23 November 2016:

I

glued the inner window panels. The acetate sheet is inserted from the

bottom side and pushed upwards. By this method, no residues of glass

cement will be visible.

|

|

...... ......

|