24 November 2016:

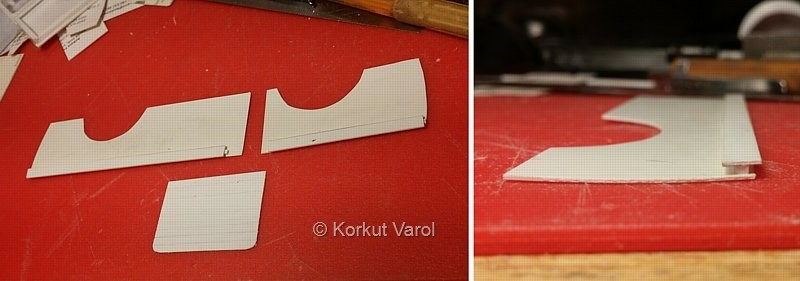

I prepared the inner frame of the

rear door.

|

|

25 November 2016:

I made the inner of the B-post,

then installed the door and checked the opening and closing.

|

I prepared the

C-post inner and glued in place.

|

28 November 2016:

Since

the vehicle was a minibus, I did not want to use the bare sheet metal

profile of the floor. So I trimmed the rear wheelwells and glued them

on the main floor.

|

I glued two magnets inside the

body to hold the door in place.

|

29 November 2016:

I prepared the

sections where the inner panels will rest on.

|

I

made the inner panels. I made the top of the panels as notches that

will mate with the bottom part of the window inner panels.

|

30 November

2016:

I started

manufacturing the roof top luggage from wire.

|

02 December

2016:

I finished the

upper part of the roof luggage rack .

|

03 December

2016:

Manufacturing

the supports of the roof luggage rack. I drilled the feet

points

of the rack through a balsa block, inserted a spacer for the roof gap

and bent the wire supports. Then I glued the upper part with

CA

glue and activator. I cut the supports where they enter the balsa block

and took out the rack.

|

I drilled

blind holes for the rack supports and placed the rack, testing for

matching.

|

I

made the stairs from wire, and shaped it to the ridiculous shape as in

the original vehicle. The stairs will be the last item to be installed

on the model.

|

04 December

2016:

The

turn signal outline in the fender was straight, and not angled like in

the facelift model. So I made a plastic substitute for the turn signal

and applied polyester putty in the remaining void.

|

05 December

2016:

I

noticed that the task was not over with just the turn signals. The

front grille height was narrower in the previous version. So I glued a

styrene strip at the lower side of the grille void and adjusted the

turn signal heights accordingly.

|

10 December

2016:

I made a shaping

die for manufacturing of round headlight bezels.

|

I squeezed a piece of acetate

between two lower layers of the die

I heated the acetate wit a heating gun and softened the acetate.

I deformed the acetate with the rod.

|

The acetate as raw outcome from

the die

Piece trimmed and headlight hole punched.

|

I cut off the lower part of the front grille to match the grille void.

|

I made the same operation above with styrene sheet and made the bezels,

glued inside the grille, applied putty and base coat.

|

|

11 December 2016:

I manufactured the bumpers from

brass U-sections. I made the rubber end for the left rear bumper from

styrene block.

|

I

made and shaped the rubber end for the right side of the front bumper,

from copper sheet and fixed it to the bumper by soldering.

|

|

........ ........ ...... ......

|