| New

Mini GT |

|

Original

Kit: Revell 7383

Date Started:

13 June 2005

Date Finished:

31 July 2005

Page 4

of 8

.

29 June 2005:

Having succeeded,

I bent a better wire to glue to the door so that it would hold better

with

a moment arm.

30 June 2005:

Now a tricky

part. Aligning the outer and inner door panels.

First I attached

the inner door panel with a masking tape in place. I prepared a dough

of

epoxy putty (the type that you knead two parts to a uniform state),

placed

it between the door panels and pressed the outer door panel to squeeze

and spread the putty between the panels.

After curing,

I took the masking tape off to reveal the door assembly.

01 July 2005:

Then I began

manufacturing the inner panels of the body door opening. I scaled the

contours

from photos.

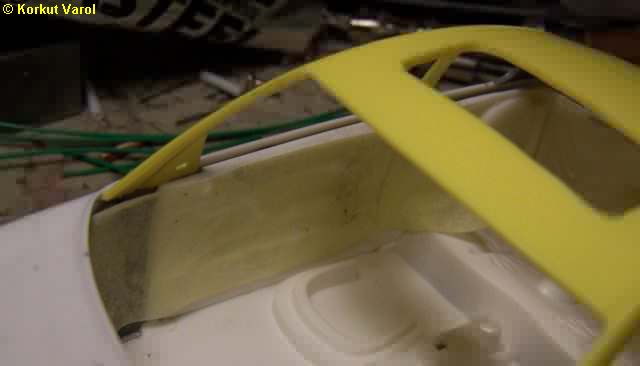

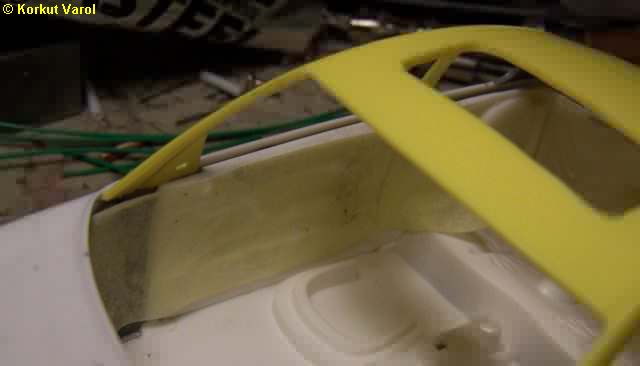

I tailored the

upper rocker panel and made a test-fit with the body.

Another test

fit with the door in place, before anything wrong may be carried on.

02 July 2005:

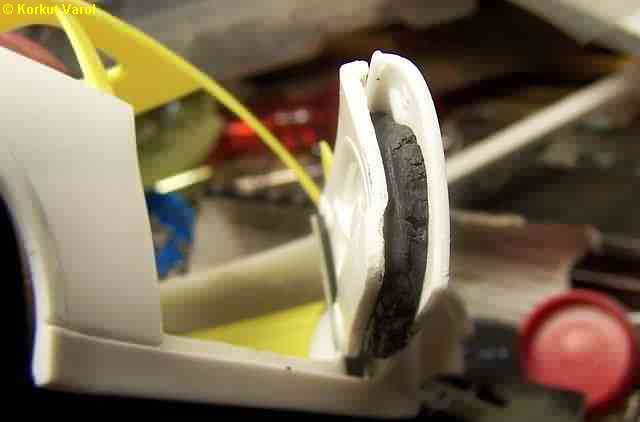

The lock striker

panel glued in place. Rough now but will look better!

I prepared

another dough of epoxy putty for the backing of the lock striker panel.

The excess were trimmed.

Now it looked

better with application of putty and sanding. Followed by another test

fit...

I placed the

striker pins into the panel. They have to be in when the door panel is

being cast in place.

03 July 2005:

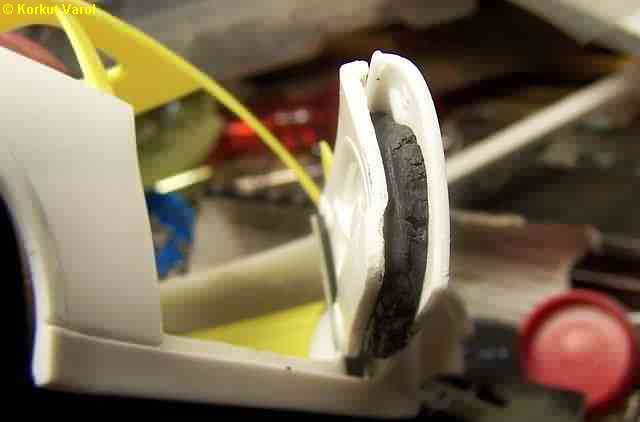

Now the turn

for "casting" the door inner rear panel to mate with the body. I

applied

Humbrol Maskol to the body, so that the putty would stick only to the

door.

I applied

automotive epoxy putty to the door and close the door, so that the

putty

was spread inside the gap. Then I leveled the putty with the door inner

panel and made the recess around the pin, before the putty settled. To

prevent the greater resistance of the pin head while opening the door

back,

I pushed the pin fully inside the body panel.

This is after

curing.

Then I applied

putty to the rest of the doors and sanded to smooth and proper shape as

in the photo.

............................

............................ ............................

............................

............................

............................