Started:

10 May 2000

Finished:

23 October 2000

Page 1 of 7

Another step

in playing with the New Beetle. Now I thought of creating a "New

Microbus" from it.

10 May 2000:

The first visual try. I used the rear

lid at the front for a steeper front profile. I mounted the windscreen

also at a steep angle and decided that I could go on.

Going on

meant cutting the roof away,

and so I did.

Since the

dashboard would be up in the

front as much as possible, I cut recesses to take wheelarches in, at

the

bottom. Notice that the clutch pedal is removed. This means that this

vehicle

will inevitably be with automatic transmission.

Now I cut the

windshield frame from the

roof and held everything together with tapes.

Taking the

windshield to the front results

in going outwards from the normal contour of the body side panel. So I

cut a pattern from cardboard, and carried the profile on the fender and

then made the contour of the hood with felt pen.

I cut styrene

pieces and glued them to

the sides of the hood.

21 May 2000:

I

separated the fender and body with a

scriber.

Now the side

panel is shifted on the drawn

contour line.

Styrene parts

were cut and glued in the

gaps between the side panel and the hood extensions.

I poured

resin in the cavities that were

formed by the styrene hood extensions at the sides and carried the

resin

over up to the side window for added strength. To have good grip, the

plastic

was roughened with the scriber before pouring.

After the

resin cured, I removed the styrene

extensions. the hood is now extended to the sides. I filed the

combination

roughly at this stage.

Now I changed

my design basis. I decided

to make it a camper vehicle, rather than a monospace minivan. I decided

to raise the roof so a man could stand up in the vehicle. This also

required

stretching the wheelbase. So I cut two styrene strips and glued them in

place in the A-posts. This will require a scratchbuilt windscreen and

other

glazing. I can do that..

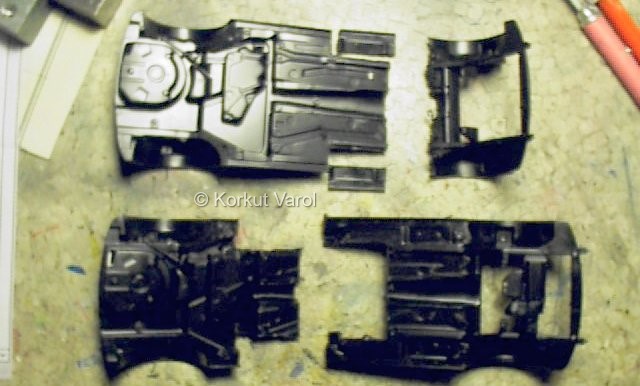

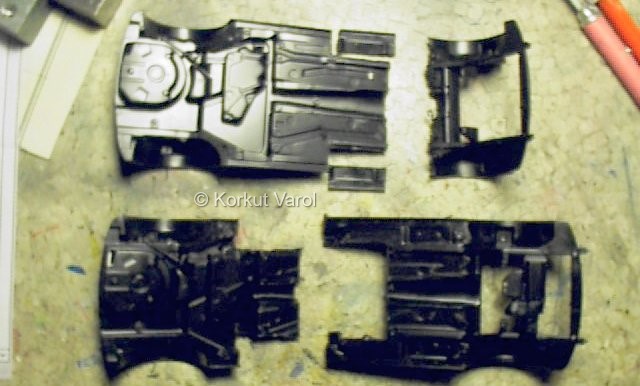

I had a

second chassis left from the Nascar

Beetle. I cut the two as shown at the right. This combination will

result

in an extension of 30 mm. (That means 720 mm in reality)

The two parts

are shown. The joint is

done in the zig-zag form to ensure a strong bond.

The two parts

are joined together, by

securing on metal blocks to ensure a level bonding.

22 May 2000:

I

reinforced the A-posts with a brass

wire bent to proper shape and bonding the whole with superglue.

............................

............................

............................

............................