1 December 2010:

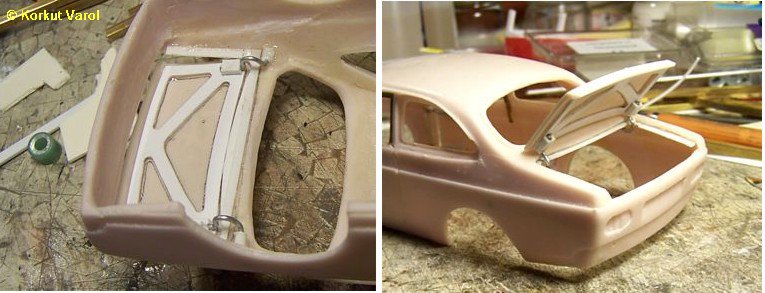

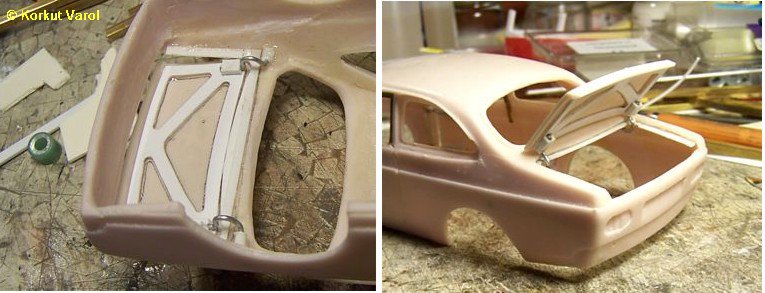

I cut out the

opening sections in the body. Since the cut parts were not re-usable, I

cast new parts.

Since

the window frames were too weak as resin, I cut them off and made new

ones from brass square rod.

5 December 2010:

I

glued the window frames to the door panel with epoxy glue. I shaved

some parts of the brass where they clashed with the inner panel.

I also cut the inner panel suitably with the door opening.

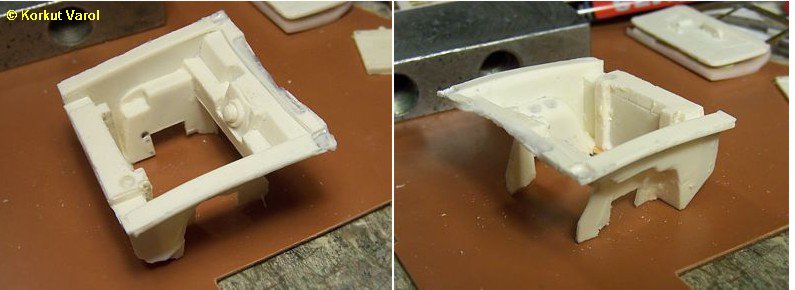

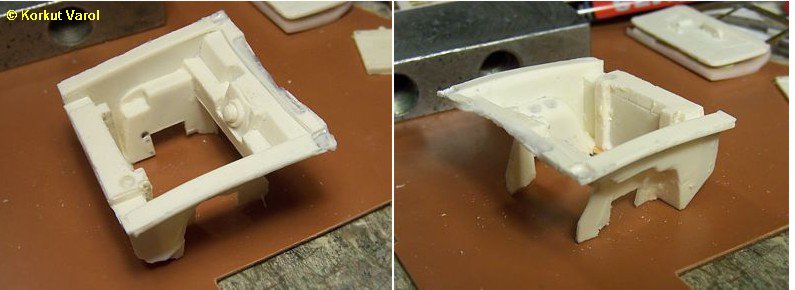

I

made the hinge and made channels in the resin for locating the hinge.

A test fit of the hinge.

7

December 2010:

I

prepared and glued the door side hinge mounts and checked the

door operation.

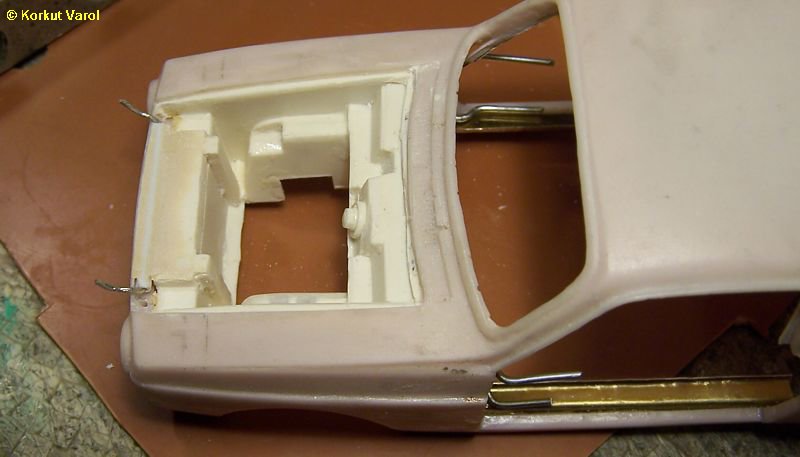

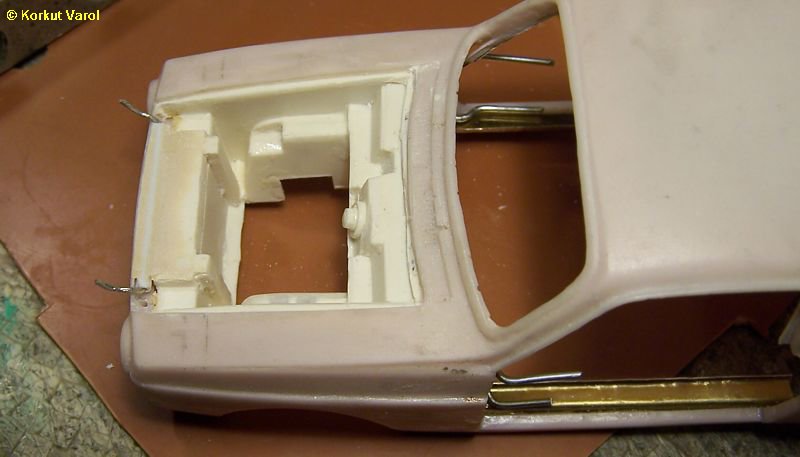

I

prepared and glued the door inners of the rocker panel. Also made the

reinforcements of the boot lid, and began making the lid resting

flanges.

8

December 2010:

I

prepared and glued the boot hinges and checked the operation.

The

first goof! The plastic strips at the inside of the rocker

panel

proved to be too thick, since mounting the floor panel resulted in

protruding of the rear footrest wells below the rocker panel.

I

took away the plastic strips

and made bent sections from brass sheet, then glued them with epoxy to

raise the final height of the floor panel.

9

December 2010:

I began making

the engine compartment panels from styrene sheets.

10 December 2010:

I carefully

shaved the frontal part where the hinge would go.

12 December 2010:

I

made and installed the hood hinge. The hood view as opened, differs a

little from the actual but this was the closest I could get to the

actual hinge rotation axis.

,

13 December 2010:

I cut out the

door mating flanges by contouring from the model and made adjustments

for a good fit.

18 December 2010:

After

completing the engine compartment panel, I made a mold from silicone

and cast a sample part. This was a hard piece, turned out to be much

better than I expected!

I

glued the engine compartment part to the body with epoxy, and applied putty to the mating

lines.

20 December 2010:

Since

the boot lid would be opening, the boot floor should fit fine to the

body inside, and be fixed. However, the floor panel, which is normally

put into place by rotational insertion would be impossible to fit. So,

I cut the back seat panel so that direct insertion of the floor panel

into place would be possible.

I

prepared and adjusted the inside panels and fixed them with epoxy glue.

................

................

................

................