|

EFES

PiLSEN

Beer

Can Truck

|

|

|

.

.

Started:

01 April 2006

Finished:

22 April 2006

Page

2 of 3

08 April 2006:

I glued the leaf

spring assemblies below the chassis.

Next, I had to

decide on what I should use for the whels and tires. Since this was a

truck

utilizing as much Efes Pilsen materials as possible, I gave up the idea

of using wheels and tires from my parts box, and went on to

manufacturing

them from bottle caps. I made a press die set for the wheel center

effects.

For the fronts, I made a convex stamping and for the rears, a concave

one.

Now

the fuel tank is glued to the chassis.

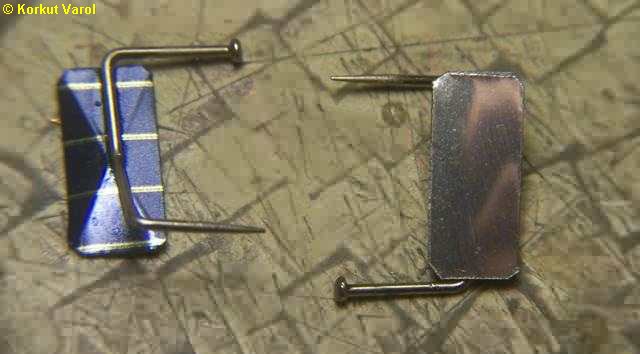

For

the differential casing, I made

two stampings from the can aluminum like the photo, and trimmed.

Parts

to form the rear axle and differential.

The

rear axle assembly.

Then

I drilled one pair of "rear wheels"

for the axle, and fixed the rear double wheels on the axle by kneaded

steel

putty between the wheels.

I

also prepared the front axle with

kneaded steel putty and steel wire, and with the wheels posed slightly

to the left.

Then

I glued the front and rear axle

assemblies to the leaf springs and got the "rolling" chassis...

For

the air tanks, I prepared the domes

by forming the beer can metal and some plastic tubing for the body.

10 April 2006:

I manufactured

the air tanks assembly by making two mounting brackets and glued them

on

the chassis too. I also made the spare wheel and the hanging bracket as

in the photo.

I

tailored, bent and installed the

ladder steps between the bumper and the mudguard.

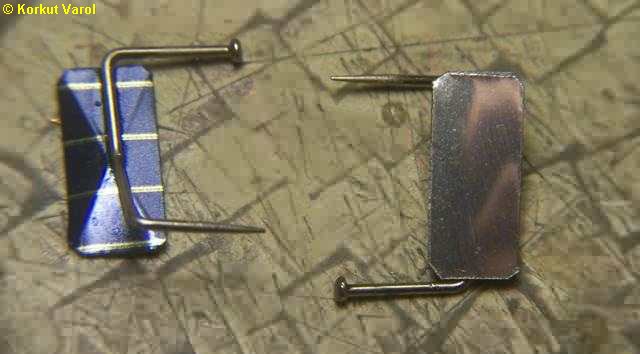

I

made the mirrors from the can aluminum

as in the photo. The mirror itself is a separate piece from a bright

polished

beer can. You can see the reflection of my fingers holding the camera...

Then

I glued the mirrors on the cab.

I

made the drive shafts from steel

rods with formed and glued joint ends from the beer can.

11 April 2006:

I manufactured

the rear mudguards.

Then

I glued in the driveshafts.

I

fixed the rear mudguards to the chassis

by brackets made from steel nails, with epoxy glue.

....................

.................... ....................

....................

....................

....................