05

February 2013:

I

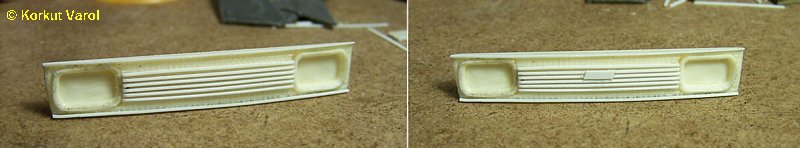

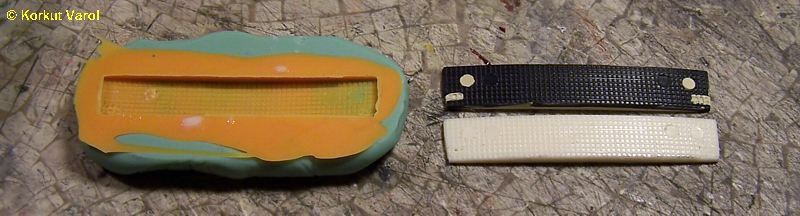

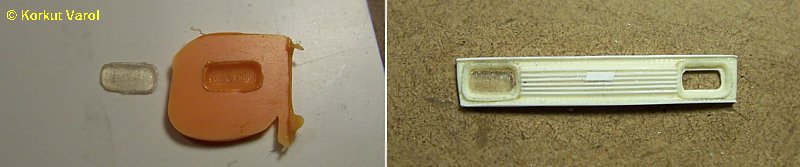

made use of the original part (rubber corners) for manufacturing the

front bumper. I cut apart the front part, made the center bumper from a

plastic "C" section.

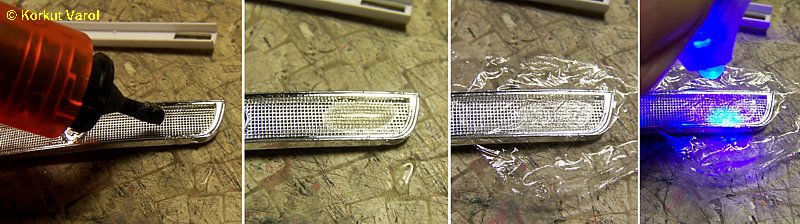

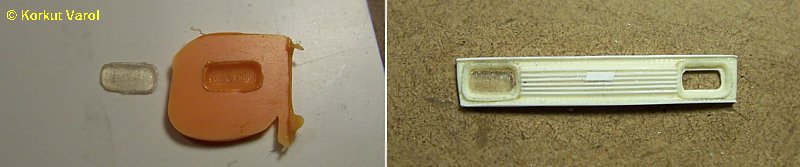

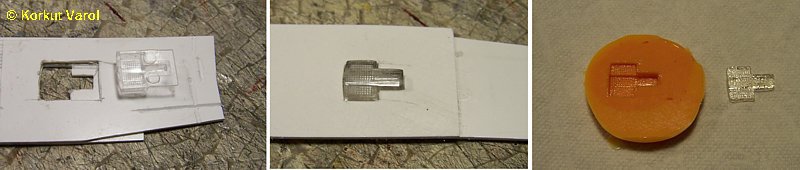

To

make the turn signal lens pattern, I found a suitable grille from my

parts box. I used Bondic (UV-curing synthetic material) for copying the

pattern. I lubricated the grille with 3M lubricant before Bondic

application, to prevent sticking. I applied a piece of stretch film

over it to make a flat part, then applied UV for curing.

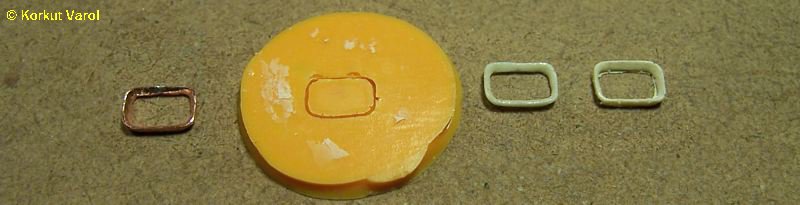

I

cut the cast patterns, then glued them behind the openings in the

bumper, then fixed the whole to the original part to serve as the

master.

10

February 2013:

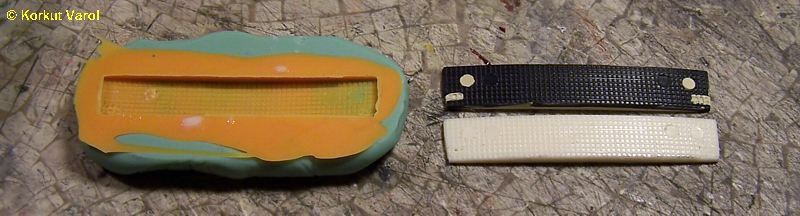

I built the rear bumper in the

same manner and made a silicone mold with both at the same time. Then I

cast resin samples.

A

closer view of the bumpers.

A

fit-check of the bumpers on the body.

22 February 2013:

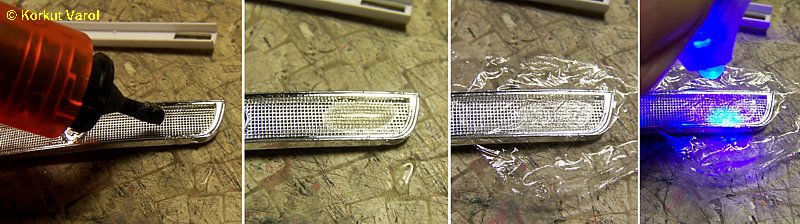

For

the front grille, I used the one cut from the original model, filled

the gaps with putty and took a mold. Then I cast a working piece from

resin.

23 February 2013:

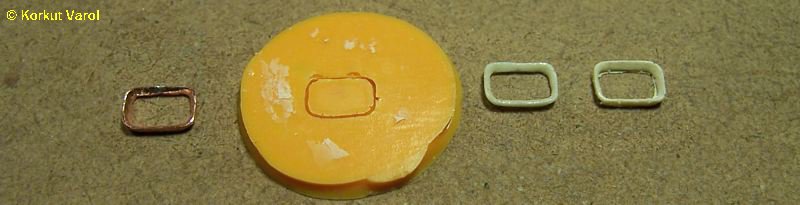

For the headlight

bezels, I used a copper wire, hammered it, bent and soldered to shape.

Then I used the copper bezel as

the master and made a mold, then cast 2 parts from resin.

24 February 2013:

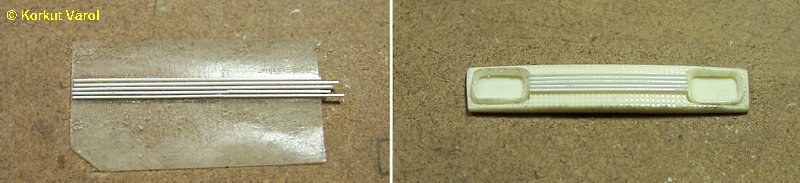

I machined the

areas where the bezels would sit, with Dremel, placed the bezels and

glued.

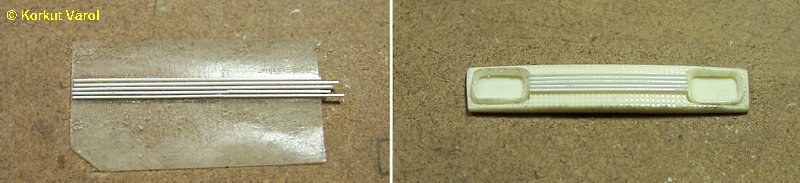

I made the center bars from

styrene, fixed them on double-sided tape and placed them on the front

grille.

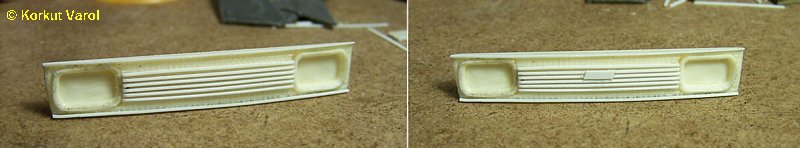

I glued the upper and lower bars,

then made and glued the emblem base in the center.

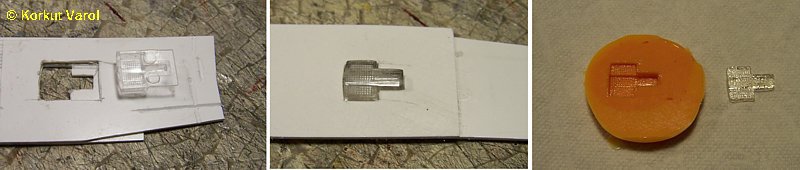

I found a suitable headlamp lens

from

my parts box, took a mold from it and cast a lens using Bondic.

Then I drilled the center, leaving only enough space for the

lens

to rest on.

A general visual check on the

body...

26 February 2013:

I made a mold from

the front grille and cast a resin part.

For the rear lenses, I made use of

the

ones from the Italeri 131 kit. However, since they were made to be

installed from the inside of the body, they proved to be too high to

stick from the outside.

The master for the mold had to be

thinner than the original. So, I placed the rear lens inside a housing,

with the proper part sticking out. Then I took a mold and cast a clear

resin part.

Visual check for fit.

...................

................... ..................

..................

...................

................... ..................

..................