|

Original photo of the carriage.

|

A few months passed with research and design. At last I completed the 3D modeling.

|

I

used 3D printing for the manufacturing of the parts.This was the first

time I tried a FDM printer. I had to make some trials to have

satisfactory outputs. Below are the chassis side elements.

|

|

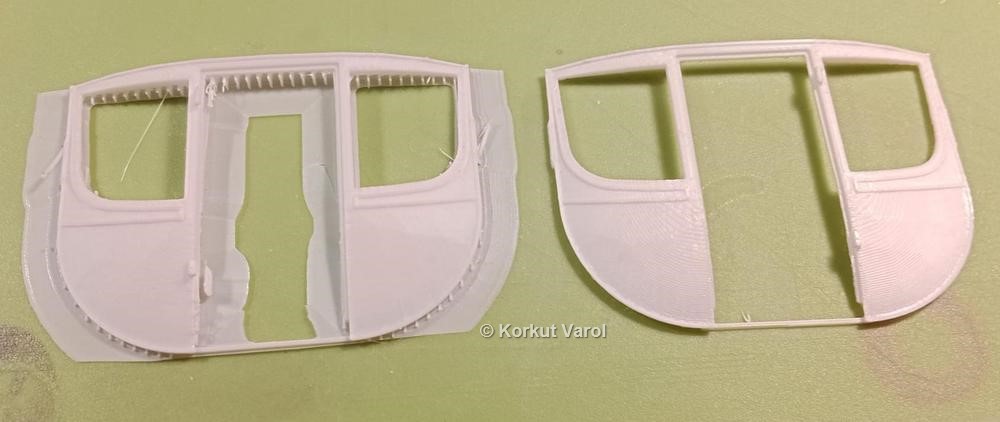

An example is the cabin sides. To print in shorter time, I positioned them horizontally. This is the outer sides.

|

The internal sides. After

detaching the supports, there were residues which lead to problems with

fitting of other elements. So I decided to position the parts

vertically despite the longer time required.

|

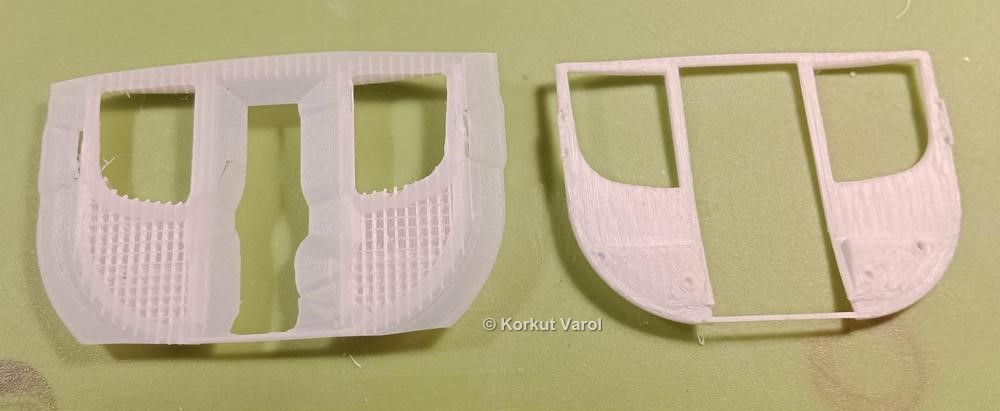

But

while printing vertically, due to insufficient supporting the window

upright parts broke. As a solution, I filled the windows with

perforated edges and after printing, separated and sanded them.

|

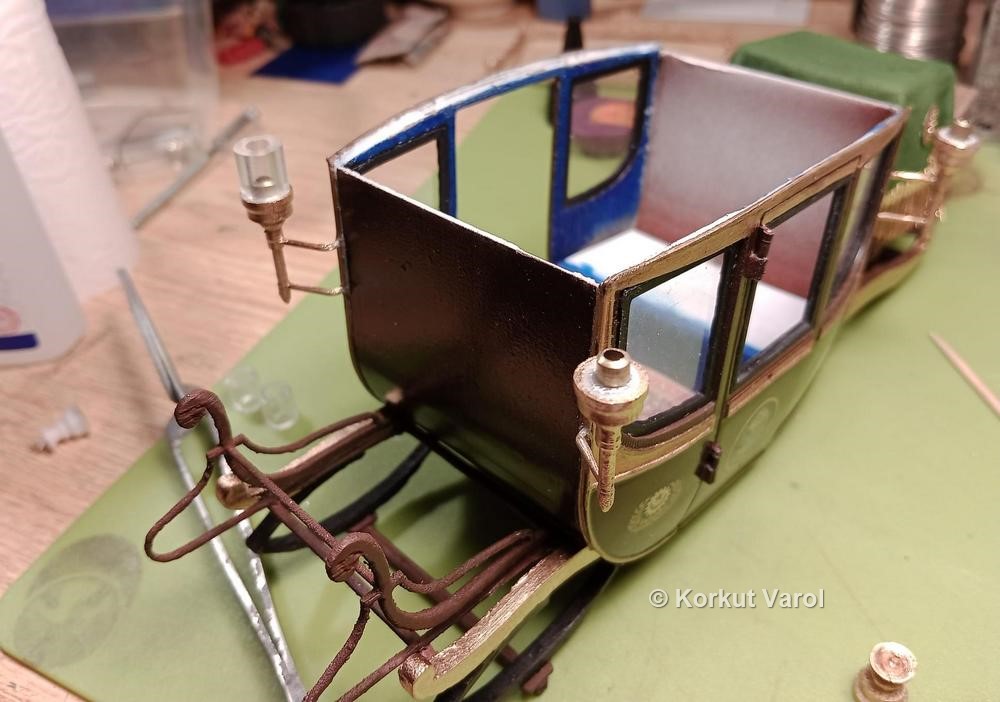

After

printing the parts, I applied putty and sanding where necessary, then

painted. I covered the seats, roof and door insides with flocking. I

made the carpet by printing on paper and glued in place.

|

|

I started assembling. I used transparent hose for the lantern glass. I used 0.4 mm steel wire for door hinge pins.

|

|

For

the cover of the horseman's seat, I soaked a piece of cloth with

diluted white glue. I placed it over the seat and formed then left it

to dry. For the brush fringe, I trimmed a piece from a ready-made one

and glued in place.

|

|

Finished photos... I prepared the decals on the computer and printed them.

|

|

|

|

The stairs are foldable and can be displayed both outside and inside.

|

|

|

|

|

|

|

|

|

|

|

The left side stairs are shown folded inside the cabin.

|

|

|

|