|

CONSTRUCTION

STORY OF

SCRATCHBUILT

STREET ROD

|

|

Building Period: 30 March 1999 - 30 June 1999

PART 11

MISCALLANEOUS AND DASHBOARD

If you remember, the front shock

absorbers

were held in place by temporary nuts made from plastic wire isolation.

It was time to manufacture real nuts. The material was a 0.6 mm thick,

perforated aluminium sheet. This was once the grille of a cassette tape

recorder. One of the holes were enlarged to 1 mm and then threaded with

M 1.2 mm threading tool. Then the nut was freed from the sheet with the

aid of X-acto #11 blade.

Here you see the union of the nut with the shock absorber.

For the front headlamps, the rear cap

of a ball-point pen seemed very suitable. Other contributors were a

wheel

retainer that was cut to fitting profile with the cap and a toothpick

piece,

to hold the assembly better. The toothpick was inserted in the

cap,

only about 1 mm protruding. The reason is, this headlamp will be placed

right over the shock absorber and its center hole will house the nut.

This

configuration will also help in partly disguising the upper resting

bracket

of the front suspension. At

the right is the headlamp body assembly.

The boomerang-shaped cutout of the

hood

blocked the first exhaust port, so its profile was changed. A big-block

Chevy engine is used to power this rod. The cylinder head and

carburettors

are from Corvette Grand Sport, by Accurate Miniatures.

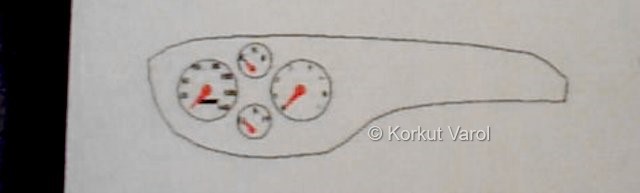

For the custom dashboard, a rosewood grained cardboard was used.

The base of the dashboard was carved from 4-mm thick balsa.

The gauges were computer-generated and printed on paper.

This is the three items' assembly.

Scotch

tape was applied over the gauges before the assembly, to imitate the

shine

of glass over the gauges.

Next, the shelf panel was made from

brass

sheet and stuck to the backside of the dashboard with CA glue. It was

painted

matt black after this pic was taken.

Holes 0.5 mm. dia. were drilled for

the

rocker switches and the ignition key. Silver dots were applied for

imitating

the bezels. Copper wire 0.2 mm dia. was painted silver and inserted

through

the holes till it protruded 2 mm from the dashboard. The excess lengths

were cut at the back, and the wires were secured by CA glue.

Dots of CA glue were applied at the

tips

of the switches and painted gloss black. Ignition key was from Detail

Master.

The glovebox handle is a pin inserted and excess part cut away.

The engine in temporary assembly with

the exhaust pipes. The exhaust pipes are made from 1.5 mm diameter

solder

wire, glued together with 5-minute epoxy. The tips are cut from

velocity

stacks of a 1/20 McLaren, and drilled for realistic looks.

The transition from the pipes to the tips are made by applying putty and sanding down to shape.

.......................

.......................