|

CONSTRUCTION

STORY OF

SCRATCHBUILT

STREET ROD

|

|

Building Period: 30 March 1999 - 30 June 1999

PART 8

THE BOOT LID AND HINGES

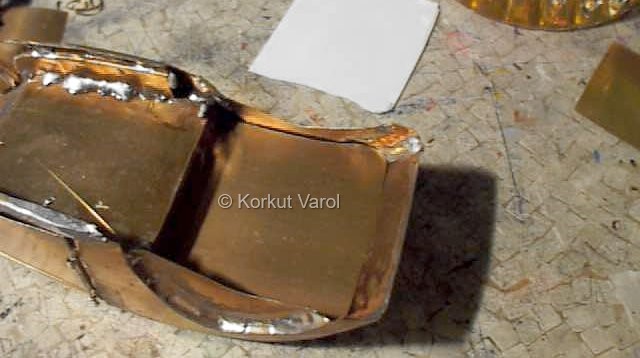

The boot lid was traced on the metal

and

cut away with Dremel. A new boot lid was made because the gap due to

cutting

tip was too large in scale.

The boot floor panel profile traced

on

to paper template (seen above the car body) and carried on to metal,

then

cut. The panel is shown while test fitting. It will be fixed into place

after the boot hinges are made and installed.

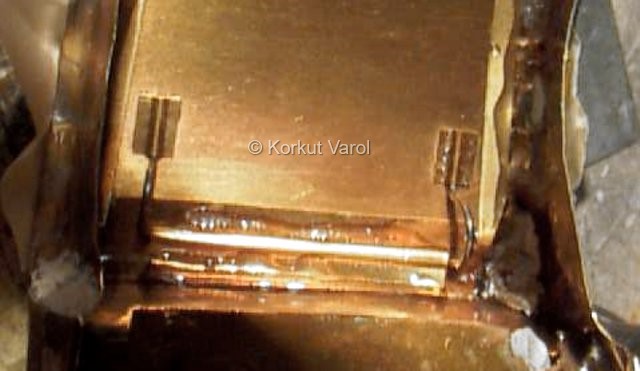

The boot hinge was made from a paper attach wire.

Thin strips

were cut from brass sheet and

glued to the body on the inside, at all edges, to serve as

the flanges

that the boot lid will rest on.

A strip was cut from brass sheet and wrapped around the wire with pliers to make a semi-assembly as shown.

The hinge assembly was glued into

place

with 5-minute epoxy. After it dried, the profiles of the hinge legs

were

checked that they fit the body contour. Some adjustments in bending

angles

were necessary to make it parallel with the body profile.

It was possible to put on the boot

lid

and then apply glue to fasten it to the boot hinge. But then, it would

be impossible to detach the boot lid if ever it became necessary during

construction. So, small housings for the legs were built from brass

sheet

as shown. A strip was put on a wire and pliers pressed upon. The final

pressing is shown aside. Two housings were prepared as shown at right.

The bootlid was put on the body, the

hinge

made to touch the boot lid and the housings stuck on the boot lid with

CA glue. After this, the housings were secured on the boot lid better

by

applying 5-minute epoxy. The boot lid was taken away from the body to

make

sure that the epoxy glue did not accidentally flow and stick to the

hinge

legs.

So, here is how it works.

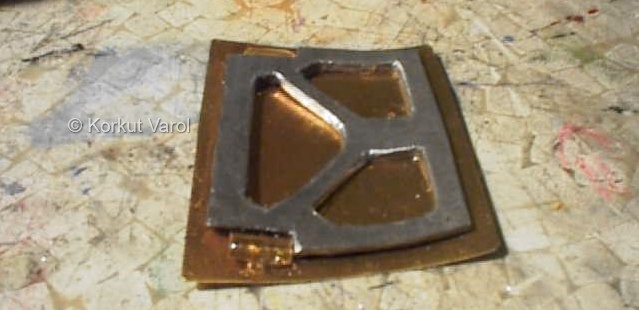

No lids are complete without

reinforcements.

A template was drawn on paper and carried on to a 1.5 mm thick lead

sheet

and the recesses were pre-cut by a paper punch.

The recesses were put to shape by hand-filing.

The edges were smoothened and part made ready for assembly with the boot lid.

Proper curvature was given by hand to fit the lid's curvature and the two were stuck together with 5-minute epoxy.

......................

......................