| The

cavities

between the doors and the floorpan skirts had to be filled with

polyester

putty, so that the floor would end where it met the door. To prevent

sticking

to the door, a piece of double-sided transparent sticking sheet was

applied

on the inside of the door without removing the protective slippery

sheet.

Then adequate putty was applied and the doors closed, defining the

final

shape of the putty. |

|

| Excess putty was trimmed with hand

filing.

Now the floorpan is complete from door to door. |

|

| The template for the hood was traced

on

a transparent paper, then transferred to a cardboard. Primary bending

of

the cardboard and making retouches to the contours were necessary till

the proper development profile was reached. |

|

| The hood is designed as a unitary

part

with the front grille and to be tilted forward. The sides of the hood

were

given a custom cutout profile and tested on the model. then the

development

was carried on to the brass sheet. |

|

|

| The center line embossing was given

to

the metal as was done with the doors. That is, three consequent

alternating

close bends. |

|

|

| The metal hood was put on the model

after

primary bending. Irregularities were overcome by re-bending and

blending

in by hand. Pliers or other tools may also be used for bending the hood

curves, but then there will be tool marks left on the metal which will

require further machining or putty treatment. |

|

| The mismatches in the levels of the

mating

edges of the doors and the body were done with the application of

polyester

putty and filing down to the same level. |

|

| The necessary places under the boot

lid

were also treated with polyester putty so that they would look unitary

when sanded. |

|

| The front grille was glued to the

hood

with 5-minute epoxy. |

|

| A general view showing that putty was

applied almost all over except for the surface of the hood. |

|

| The hood was put on the chassis, and

the

front end profile was cut in parallel with the front grille

inclination. |

|

| The bottom fronts of the chassis were

opened up with pliers so that the side plane of the chassis was

extended

to front lower part. Then one hole 1mm dia. were drilled on each side.

Next, this latter formed parts were bent back again, but with an angle

with the chassis at first, then given the next opposite bend to form a

drilled bracket hanging down the inner sides of the chassis. |

... ...

|

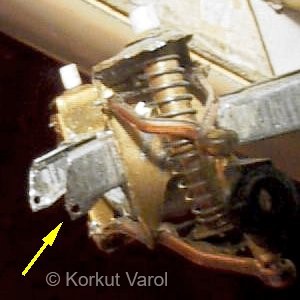

| Two L-shaped brackets were made from

brass

sheet and glued with 5-minute epoxy from the inside to the hood. Then

the

hood was placed on the chassis again, matching with the body, and

secured

with masking tape to preserve relative positions. Then the holes were

drilled

on the hood brackets using the holes on the chassis as drilling

jigs. |

|

| This is how it looked after the holes

were drilled. To smoothen the level difference of the hood and the

pivoting

bracket, putty was applied and sanded down to smooth transition. |

|

|

|