| 28

October 2001:

I constructed the rear outer

panel by a straight styrene sheet at the center and filled the corners

with polyester putty. The pic shows the cab before the putty

application.

|

|

| Putty mess

after the application. |

|

| View after

the first sanding. The rear overhang seemed too bulky and reduced the

ramp

angle, so I marked a cut-off line. |

|

| 21

November 2001:

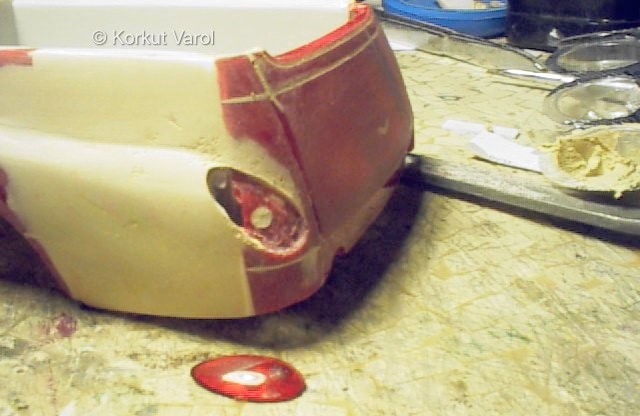

For the rear lamps, the

housings had to be carved in the plastic. I did the job with Dremel,

and

applied polyester putty around the lens to take the exact contours. To

prevent the putty from sticking to the lens, I applied Humbrol's Maskol

on the lens prior to putty application.

|

|

| Here, you see

the putty with the lens taken out and sanded. The fender bulge upper

contour

had a wobbly profile, and it would be corrected as shown next. |

|

| This is the

restoring putty application for the fender bulge. Also, note the

filling

styrene pieces at the remaining gap from the rear window and the rear

bumper

panel. |

|

| Now the floor

panel. Since the chassis members were protruding in the cabin, a

beveled

panel was tailored on the floor. Also, a recess in the firewall was

made

to make room for the rear part of the engine. |

|

| I tailor-cut

the side panels, and filled the rear parts with putty after shaving the

armrests and rear door pockets. |

|

| As for the

rear bumper, I found a chromed part from my parts box and gave the same

curvature with the body. I drilled two holes to house the bumper

supports. |

|

| The first primer

coat. I had to apply putty and sanding to the bed to get a smooth

finish. |

|

| For locating

the tent, I buried two pins into the plastic with heating by solder

gun.

I then applied super glue over them to finalize the fixing. The small

pin

you see at the very right is a broken one, with the embedded part being

impossible to remove. |

|

| On the mating

part of the cab, I drilled two holes to house the locating pins. |

|

| For the bed

floor, real wood was used. I applied a coloring protective to the wood

to give it a proper color. |

|

| Meanwhile,

I painted the car with metallic dark green. I fabricated the peripheral

bars from brass rod and applied bare metal on it for chromed look. I

also

applied bare metal to the lens housings for a brighter lens finish. I

was

too fast even for myself, I forgot to take pics during these steps! |

|

| Returning to

the wooden bed floor again; I cut strips from the painted and now dry

wood.

As in the following pics, I first laid them on a sticky paper, and

glued

the bed profile from a card on its back. (Old business cards are good

for

such jobs). Then I cut the whole thing out, accordingly. To make the

wood

grain stand out more in contrast, I sanded a little from the surface,

so

that the parts that absorbed paint seemed darker. Then I applied

another

coat, that resulted in lighter and darker shades of the same grain in

more

contrast. |

|

|

|

| I painted the

dashboard and side panels, and the seats. I applied carpeting on the

floor

with cutting from self-sticking black velvet. |

|

|

|

| Since the chassis

was interfering with the snap-tite kit's lens and reflector parts, I

cut

them all into individual parts. |

|

| I assembled

the lenses with Testors Clear Parts Cement as shown, and also the

reflectors

the same way. |

|

| Then I located

the engine in accordance with the internal tub, and glued it in place. |

|

|

|

|

|

| |

|

| |

|