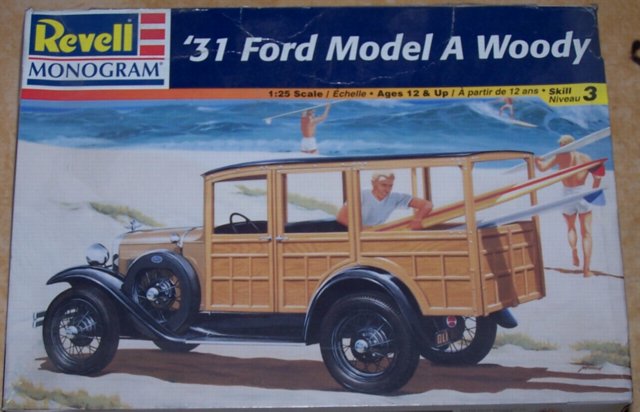

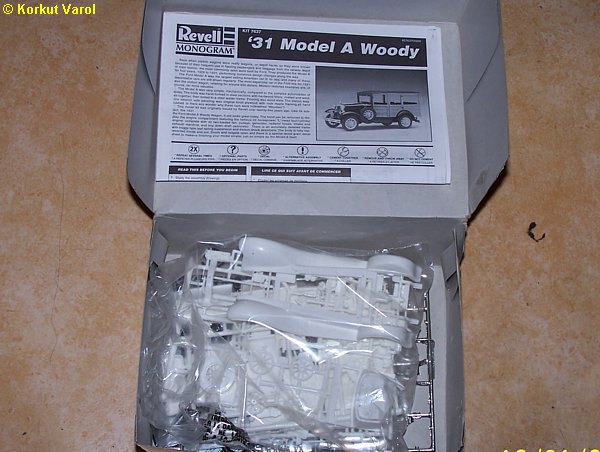

12 January

2009:

This is the

box and its contents.

.. ..

|

13 January

2009:

I started with

the front axle group. A

big negative for the kit was that, all the suspension, drivetrain,

steering

and axle elements were molded in chrome, so I had to make lots of

scrapings.

The tie and

push rods were very weak

and securing the joints as described in the manual was tricky and not

reliable.

So I built them from paper clip wire.

|

|

I

secured the rod ends with droplets

of CA glue.

|

14 January

2009:

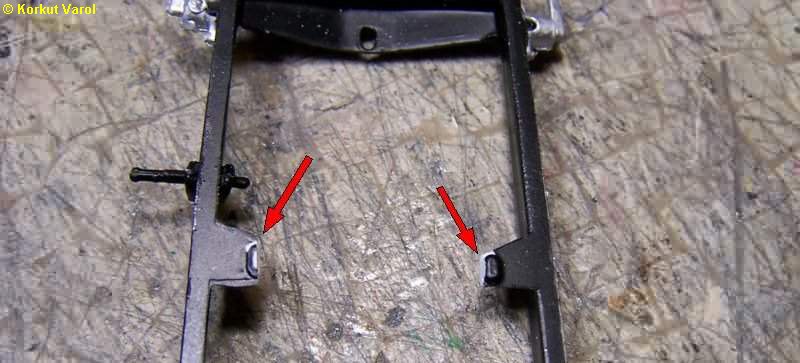

After

assembly, I painted the front

and rear groups with flat black.

|

16 January

2009:

I drilled the

holes for the circulation pump shaft that I intend to make from metal

wire

later.

|

17 January

2009:

Meanwhile, I

cut the hole in the left

fender and then glued the spare wheel housing in place.

|

|

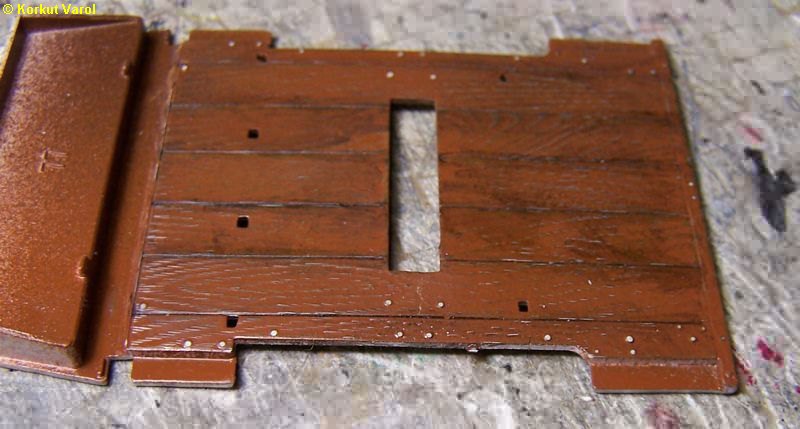

For

a trial, I painted the floor,

weathered it with #2000 and some blackwash. Not bad, maybe I can work

more

on it later..

|

|

18 January

2009:

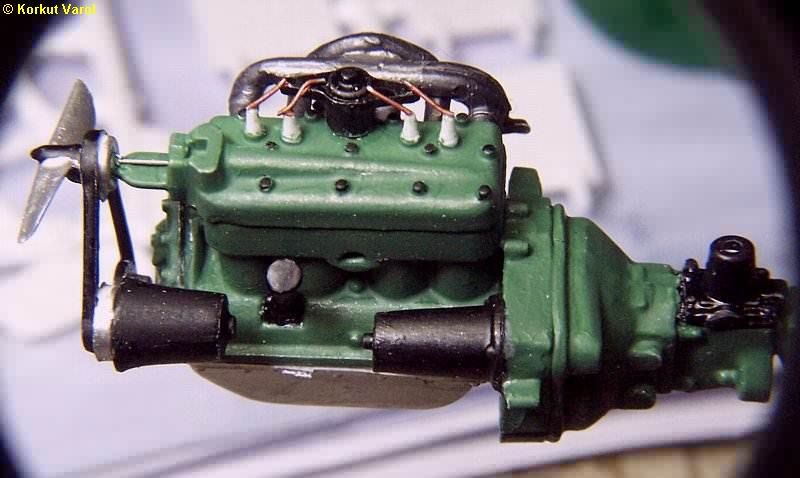

I assembled

the engine, but when it came

to installing the manifolds, I saw that the branches of the inlet and

exhaust

were different to fit on the block. So I cut the excess lengths from

the

exhaust manifold to make them even.

|

| And

this is the assembled engine so

far. Note the circulation pump shaft that I cut from an aluminum wire

for

better realistic looks; as well as the spark plug wires between the

distributor

and the plugs.

|

|

The

flywheel housing did not go

through the engine mounting brackets, so I had to trim them off.

|

21 January

2009:

Both of the

front door lower hinge

pins were either broken or not moulded well, so I had to manufacture

them.

I drilled 0.5 mm holes in the hinge bodies.

........ ........

|

|

I

inserted a copper wire in proper

length and fixed with CA glue at both lower sides.

|

|

24

January 2009:

Until now, the

worst part of manufacturing

are the wheels and tires. The tires had a central hump on the inside,

which

made an impossible-to-pass barrier for the wheel. It was also

impossible

to glue the two parts of the wheel from either side of the tires

because

applying pressure would break the tender wheels. So I had to trim off

the

central hump so that I could slide the wheel inside the tire after

glueing

the inner and outer parts. However, I still had a breaking disaster

with

both of the front wheels while pushing inside the tires.

.... ....

|

25 January

2009:

Repairing the

wheels, I managed to

assemble the rolling chassis.

|

|

I

glued the lower body which I

had painted before, on the rolling chassis.

|

31 January

2009:

The dashboard

had pushing pin marks

on the face, so I applied putty. Then I engraved some wood texture with

the back of #11 blade.

.... ....

|

03 February

2009:

I painted the

dashboard and applied some

dark brown wash on the wood grains. Instead of applying decals, I

painted

the gauges and applied water droplet gel for a convex finish.

|

|

|

| |

............ ............

|