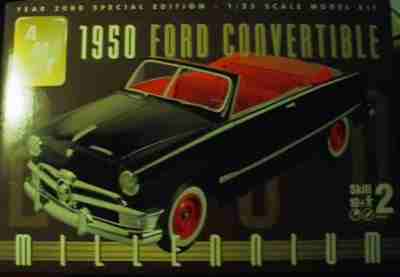

| This

is the donor kit. |

|

| These

two pictures are as the kit arrived to me. The right B-post and part of

the door was broken. |

|

| On

the left door, there were two breaks in the door panel too. |

|

| I

began cutting the openings with my Dremel, taking good precaution

against

dusting. While cutting, I held the piece close to the hose of a vacuum

cleaner, which I held between my thighs (tip of hose seen just behind

my

left hand). |

|

| OOOPPS!!!

Some part of the door broke apart while filing! I temporarily fixed it

back in place with CA glue. |

|

| Now

the remedy for the B-post. I made a foil mold, covering the gap made by

the missing part and fixed it on the body by tapes. |

|

| On

the left door, the breaks were minor so I put a masking tape on the

outside

and placed a piece of foil (folded a couple of times to build some

thickness)

at the upper level of the door panel. This foil edge will stop resin

from

flowing away. |

|

| I

poured resin in the foil mold |

|

| and

also to the left door. |

|

| After

curing, I ripped the foil away to display the roughly filled resin. |

|

| This

is the left door after cure. |

|

| l

scribed the door line and glued the quarter window bar made from

styrene. |

|

| March

11, 2004:

I cut

the front internal panels from the donor kit to transfer to the UTE.

|

|

| The

hood is serving as a fixing template for the assembly. To prevent

sticking

of the glue to the hood, I put masking tapes on the edges of the hood

and

then fixed the taped hood on the body with another masking tape on the

outside. |

|

| Then

I applied epoxy glue along the mating edges. |

|

| Taking

off the hood, the front part is fixed. |

|

| March

13, 2004:

I cut

the inner tub to suit the shorter cab of the UTE.

|

|

| I

tailored and built the bed from styrene sheet.. |

|

| ..and

fixed it to the body with epoxy glue. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|