| March

19, 2004:

I drilled

recesses to house the taillights. I will use bullet type taillamps and

not to protrude too far behind the body, there had to be blending

housings.

|

|

| I

filled the gaps with automotive putty (meanwhile other defective places

on the body too). But they had to be grinded to a sharp and flat base. |

|

| With

this home-made grinder tip (well, it was a screw) I machined the

taillight

putty region. |

|

| Here

is the sharp, machined base. |

|

| Since

the bullet lenses were wider than the place left beside the bed door,

it

seemed evident that I had to manufacture blending-with-the-body

housings.

So I machined the recesses a bit more to make space for the plastic

tubing

parts coming in. |

|

| These

are the adapter housings made from styrene tubing. I had to enlarge the

internal diameter with a drill. |

|

| I

fixed the housings with epoxy glue... |

|

| ....and

filed and sanded them to blend with the body. |

|

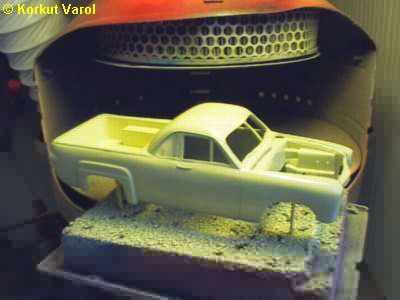

| Now

the UTE deserved the first primer coat for further corrections. |

|

| March

21, 2004:

I Cut

open the inner tub for easier painting of the door inners.

For

the seats, I chose to use the ones from a PT Cruiser kit.

|

|

| The

hood had some gaps with the fenders, so I decided to fill them with

putty.

To prevent sticking to unwanted places, I covered them with Humbrol

Maskol. |

|

| I

applied automotive putty to the gaps and closed the hood, forming the

putty

in between to shape. |

|

| Here

is after curing and sanding smooth. |

|

| I

put styrene sheets over what was the back seat before, now serving as a

closed luggage or tool cupboard. |

|

| I

covered the top with self-sticking felt sheet and the front with wood

imitation

glossy paper. |

|

| I

prepared the door inners by painting. I put green felt on the lower

part

and BMF for the kicker plates. |

|

| Here

is the inner tub assembled less the dashboard. |

|

| I

prepared the engine and painted it the same color with the body. |

|

| I

painted the dashboard with a different shade of green. The bezels and

finials

are chrome-painted. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|