20 December 2010:

I filled the space between outer

and inner door panels with polyester putty and made a pre-sanding.

|

12

January 2011:

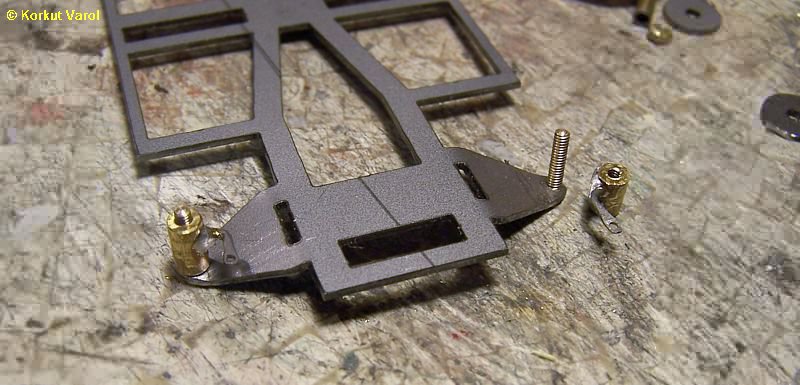

I

had the chassis cut in 3 pieces with a laser cutter, from steel sheet.

I wanted to make a poseable front end. To achieve this, I drilled and

tapped the ends of the wishbones with M2 thread. I cut the heads of two

M2 screws and installed in place, gluing with superglue to prevent

rotation. I prepared the "kingpins" from a 4 mm dia. brass rod, by

drilling and tapping with M2 thread. I also tapped M2 threads to hold

the axle pin. I prepared the steering arms from 1.2 mm steel wire,

flattening and drilling 1 mm hole at one end. Then I bent the wire and

inserted one end to the kingpin, then fixed by soldering.

|

|

I

inserted M2 nuts inside 5/32" washers and glued them with superglue

(brake discs). Then I screwed the brake discs on the M2 axles and made

ready for wheel mounting. Later, a tie rod will be manufactured.

|

15

January 2011:

The

steering arms did not prove to have proper steering geometry, so I

dismantled them and made a new set. I also made the tie rod from 1.2 mm

steel wire and made a brass tube housing. I fixed this housing to the

chassis with epoxy glue.

|

21

January 2011:

I

made and assembled the rear axle group. I cast the differential over a

4 mm styrene tube, then inserted the axle through the eyes of laser-cut

rear springs and fixed with superglue. Then I made a brass bar with M2

threads at both ends. I prepared the "rear drum surfaces" by inserting

M2 nuts inside M4 washers and screwed them on the threaded axle. I

fixed the assembly to the chassis with epoxy glue.

|

23

January 2011:

Using

the wheel from a Ford Escort kit, and a suitable tyre, I

made a smaller offset wheel and tyre to manufacture a silicone mold.

Then I cast wheel and tyre assemblies from black resin, and painted.

|

24

January 2011:

I

cut a universal joint from my parts box, made a mold to make the joint

before the differential. Then I cast a part from marble adhesive at the

end of a styrene rod, then glued the part in place.

|

|

I

began detailing the engine. I made the fan from brass sheet. I made the

distributor from styrene rod and made the cable holes with a heated

needle. For the air filter, I used a metal washer and glued pieces of

styrene below.

|

31

January 2011:

After installing the spark plugs

and cables, I glued the other components to form the rolling chassis.

|

I filled the gaps at the door

opening rear with automotive polyester putty.

|

06

February 2011:

I bent a roll-bar from 2 mm

solder wire and checked the fitting.

|

Since the doors were opening,

the seats had to be realistic. So I cut the bottom of two seats to

proper thickness. I

prepared the seat legs from steel wire, inserted them in the holes I

drilled at the seat bottoms, then glued them in place.

|

13

February 2011:

I

shaved the cast window crank arm from the door insides. I drilled the

center and made a crank arm from a headed pin to be placed in place

later.

|

I fixed the boot floor inside

the body and applied a test primer.

|

14

February 2011:

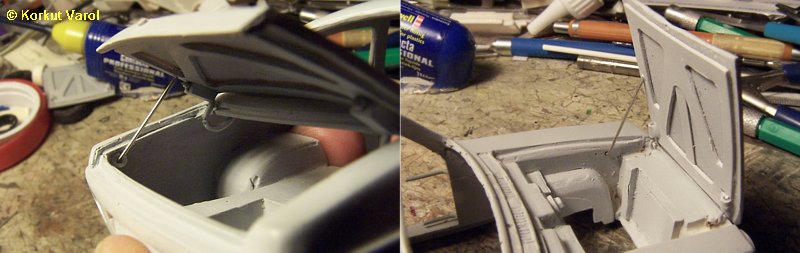

I made support rods for the boot

and hood from 0.8 mm wire.

|

16

February 2011:

I made a template for the roof

lining, cut from masking tape and applied it under the roof.

|

|

17

February 2011:

I

made U-bolts from 0.8 mm wire to hold the seats in place, plus act as

hinges. I drilled the floor panel at suitable places, installed the

seats by glueing the U-bolts with CA glue from below. The seats can be

folded just as in the original car. I also painted the roll-bar and

fixed it into place with CA glue.

|

|

After some painstaking masking,

I painted the body. Some minor overflows will be retouched later.

|

..... .....

|