20 February 2011:

I

made the brake and clutch master cylinders by installing pieces of

plastic rods at the ends of steel wire pieces, then inserted and glued

them in place. I made the battery from a piece of rubber eraser, the

cell caps and the battery poles from pieces of steel pins. I tied two

cables at the poles and let them hang down.

I printed the decals I

prepared on the computer on white decal sheet and applied them on the

body parts. Then I applied a protective clear coat.

|

21

February 2011:

I

made the boot floor cover by painting a patterned business card. I also

made the spare wheel but had to cut at its underside since it was a bit

larger than the housing. Anyhow, it is beyond sight :-)

|

Disaster!

While painting the inside of the doors, I had masked the

outside.

Though I had weakened the sticky side, when removing the masking tapes,

the decals came off too... The clear coat was not firm enough then...

So I had to make and apply the door decals again.

The moral from the

story: If a decaled surface has to be masked, a piece of paper is

better be put between the tape and the decal.

|

23

February 2011:

For

the spotlights, I used some suitable ornament parts that I saw at a

store. I drilled at the bottom, inserted a pin and cut to suitable

length. I opened the channels to put the pins in, then fixed with

superglue.

|

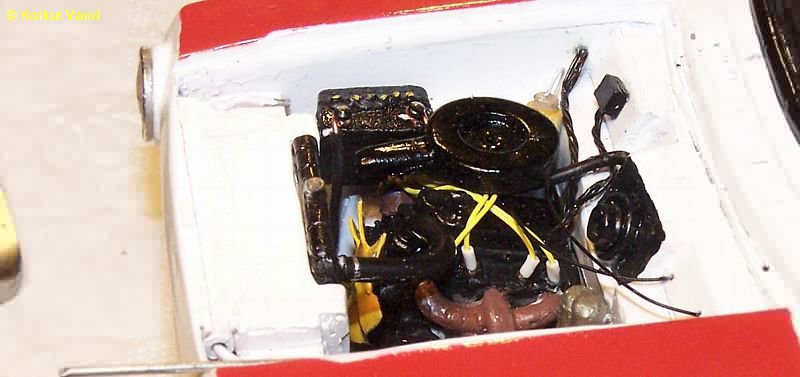

I

went on detailing the engine bay. For the heater and radiator hoses, I

used solder wires of different thicknesses. I made the clamp look by

scratching the black paint. I used 0.35 mm wires for the speedometer

and throttle linkages. I also used the same 0.35 mm wire for winding

the groups of cable harnesses and fuse box. For the screen

washer

bottle that I made from plastic rod, I mixed clear green and flat white

for the liquid part. After drying, I made a white mist over and got a

realistic look.

|

|

Manufacturing the rubber security

locks for the hood and boot lid:

1- I engraved a female mold within a resin part.

2- I applied hot melt black plastic with a glue-gun tothe mold.

3- I cut off the excess from the surface with a knife.

4- The part is ready to be taken from the mold.

5- Parts taken off the mold.

|

And the happy end...

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

..... .....

|