01 April 2006:

I started with

the front of the cab. The shape of the draft beer can was suitable for

the job. |

|

| Next, I cut and

bent the main frame bars. |

|

02 April 2006:

I manufactured

the traverses and the rear bumper, then fixed them together with epoxy

glue. Since the material is aluminum, either CA or epoxy glues were

used

throughout the model manufacturing. |

|

| I cut the side

panels, positioning the template such that the side paint themes are

symmetrical

and matching with the front panel too. |

|

| I punched 4 holes

for the headlamps in the front panel. |

|

| Then

I glued the front and side panels

of the cab. |

|

| I manufactured

the roof and the rear panel of the cab and glued them too. |

|

| Then

I added the front bumper. |

|

04 April 2006:

For the front

mudguards, I made use of the can bottoms. I hammered the

circumferential

extensions for smoothing the surface and then cut into two halves. |

|

| I

cut out the wheelarches and glued

them under the cab. Meanwhile, I placed acetate sheets, painted black

on

the insides for the glasses, to look like dark solar film was applied. |

|

05 April 2006:

I completed the

front mudguards by cutting filler strips and glueing. |

|

06 April 2006:

I went on to

manufacturing the leaf springs. I did not use the aluminum beer cans

here,

because they broke easily when forming the spring eyes. Instead, I used

the tin from a thinner can. |

|

07 April 2006:

The same was

the case for the spring mounting brackets. I manufactured them from tin

sheet. |

|

| I

finished the spring assemblies, by

installing with pins on the fixed and shackle ends. |

|

08April 2006:

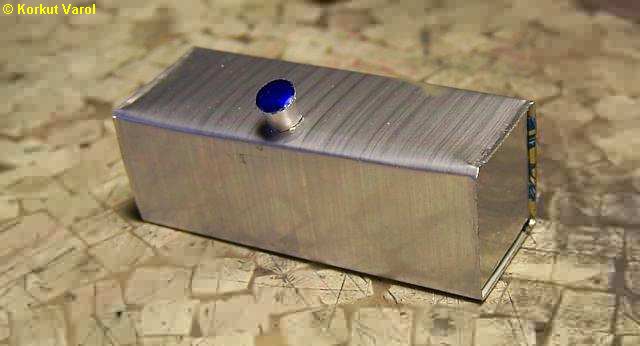

I cut the development

of the fuel tank... |

|

| ...and manufactured

as in the photo. I imitated the seam welds by a slight bend at the

edges.

I used the punched part from the headlamp recesses for the cap. |

|

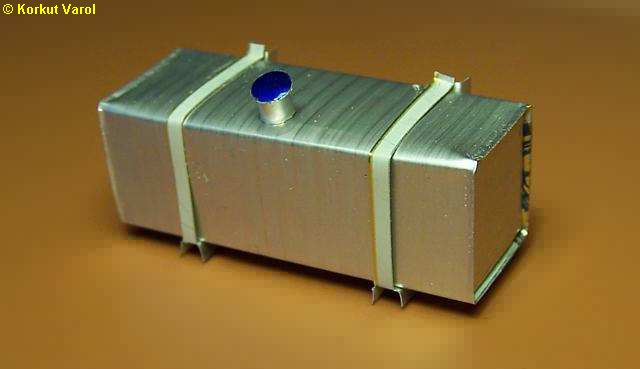

| I

manufactured the tank brackets and

steel fixing belts from a single aluminum piece. |

|

| The

tank assembly is finished and now

ready to be fixed on the chassis. |

|

|

|

|

|

|

|