25 April 2009:

I covered the

roof inside with florists' wrapping paper. |

|

| I made the pedals

from wire and styrene pieces, and glued in place. I carved the steering

column from balsa, and made the signal and wiper arms from 0.35 mm wire

with CA glue droplets at the ends. |

|

27 April 2009:

I manufactured

the armrests of the door insides from styrene pieces. I shaped the

pull-arms

of the front doors from soldering wire and fixed to styrene parts with

CA glue. Then I sanded the tops smooth. |

|

| A last look at

the inside before closure. I made the "sponge wraps" on the roll cage

from

masking tape, and the belts from computer printout. |

|

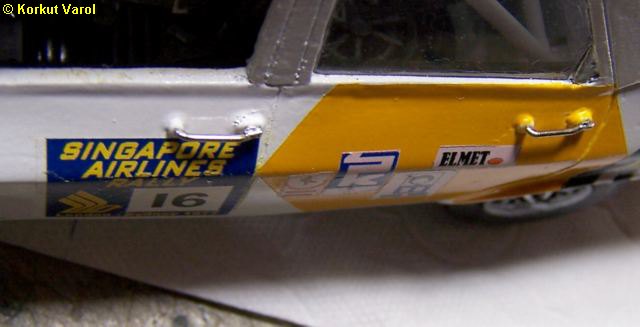

| I had previously

made the patterns and decals on the computer. I printed them and began

applying on the body. Since the inside was finished, I assembled it

with

the body. |

|

29 April 2009:

I glued the engine

block and the radiator in place with epoxy glue. |

|

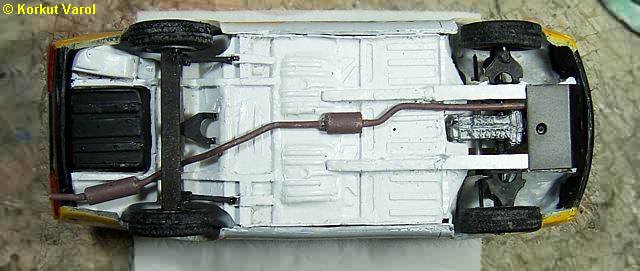

| I

painted the exhaust pipe and fixed

it in place with epoxy glue. I built the oil sump guard from brass

sheet,

painted and fixed in place. Then I glued in the rear axle and

suspension

assembly, the front wheels and the axles. |

|

01 May 2009:

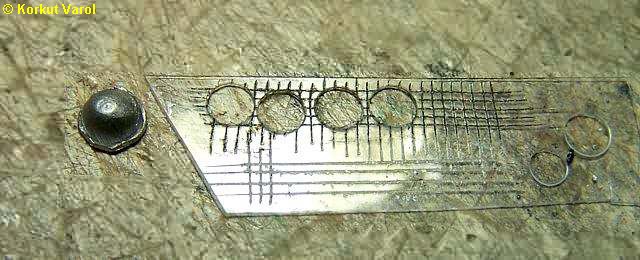

I made the frontal

spotlights by press-forming lead sheet to a reflector and the lenses by

scribing stone guards on a piece of acetate sheet. I filled the

reflector

cones with Humbrol ClearFix and put the lenses in front. |

|

| I

formed the door handles from steel

pins and glued them in place with CA glue. |

|

| For

the grille, I used a piece of Detail

Master screen painted black. I glued the spotlights on the guard bars,

then the whole assembly on the front of the car with CA glue. |

|

| For

the solar film, I used automotive

mirror solar film and taped the film on a paper sheet, then put in a

laser

printer to print "TURKEY". I fixed the film with water, just like in

real

cars. For the hood pins, I used Detail Master PE sets and did the

safety

switch from styrene sheet. |

|

| I

manufactured other important items

in the engine bay and fixed them in place. |

|

03 May 2009:

I made the rear

spotlight by press-forming lead sheet to a reflector and the lens from

my parts box. I filled the reflector cone with Humbrol ClearFix and put

the lens in front. |

|

| For

the antennas, I used 0.30 mm aluminum

wire and glued them in the holes I opened in the roof by CA glue. |

|

| I

used brass sheet for manufacturing

the mirror bodies. |

|

| I

formed the stems of the mirrors from

paper clip wire. I drilled holes on the back of the mirrors and put the

stems in, then filled the inside with CA glue; to fix the stems and to

form a surface for the mirror itself. Then I covered the whole with BMF. |

|

| I

fixed the mirrors on the body with

CA glue. I used Detail Master Photoetch set for the wipers. |

|

|

|

|

|

|

|