| The drag link between the drop arm

and

the bellcrank is made from 0.2 mm brass sheet, both ends drilled 1 mm

dia.

and bent as shown. Later it was painted gloss black. |

|

| The joint here is a pin , prevented

from

slipping by a drop of CA glue and excess part cut off. |

|

| The drag link now connects the

bellcrank

and the drop arm. The drop arm is also made from 0.2 mm brass sheet,

two

holes of 1 mm dia. drilled at both ends. The length of this part is

only

4 mm. |

|

| The left track rod is made just like

the

drag link, with the only difference being that the hole at one end is

C-shaped

by a cutout. This provides the fitting of the link on the steering arm

by a light push. The other end is jointed to the bellcrank by passing a

nylon guitar string 0.8 mm dia. through the holes and riveting by

squeezing

with a heated tweezers. |

|

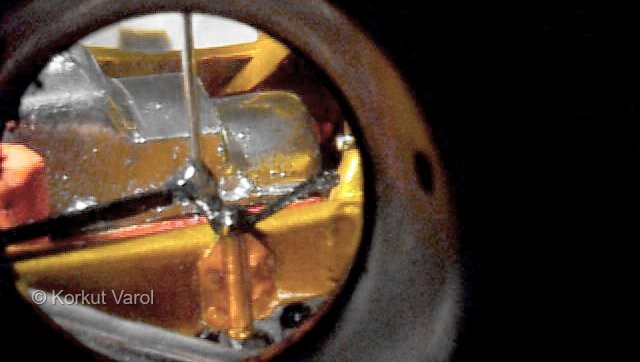

| A close-up of the push-fit joint of

the

left track rod. |

|

| The main track rod connecting the two

front wheels is constructed from 1 mm dia. paper clip wire. The two

ends

are thinned in section and bent as shown. A push-fit is aimed as well. |

|

| The steering mechanism is completed

and

the motions are tested to a full left and full right as shown. |

|

|

| The radiator, fan and radiator hoses

(made

from insulated copper wire) are glued in their places with 5-minute

epoxy. |

|

|

|