| The battery is from the parts box.

Its

fixing bracket is made from lead sheet and the tightening rods from

copper

wire. The assembly is held together with CA glue, and fixed into its

place

in the boot with CA glue as well. |

... ...

|

| The fuel tank is carved from balsa

and

painted gloss black, then fixed under the chassis with CA glue. |

|

| Now the chassis is complete, waiting

for

the body parts to be assembled on. |

|

Unfortunately, there were no headlamp

lenses in my parts box, so a pair was made from scratch. Acetate sheet

was forced with the thumb into a convenient concave recess, and given a

slight spherical surface. Then, with the backside of the tip of the

famous

#11 blade, scratches were made on the inside of the lenses, to resemble

the prismatic profiles.

The lenses

were cut from the acetate sheet

at a suitable diameter to fit in the reflector/bezel units and glued

with

white wood glue. This glue is very convenient to use with clear parts,

or other places where no risk of damaging the surrounding is

tolerated. |

.... ....

|

| The hood was the first part to be put

on the chassis. A pin went through the holes in the chassis and the

hood.

The pin was cut to suitable length and secured with CA glue. |

|

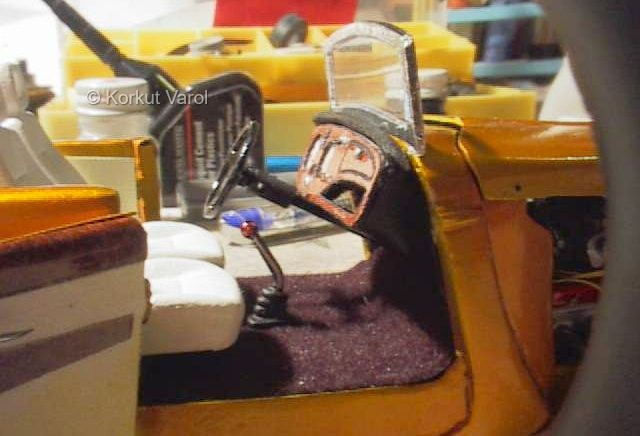

The dashboard is fixed on the body

with

CA glue.

The steering wheel is

from my parts box.

The steering column is 1.5 mm brass wire, its housing is cut from cable

isolation, and the switch stalks are made from pins. All are held

together

and glued to the body by CA glue. |

|

| The trunk should have a handle, and I

chose to make a working one. A hole 0.8 mm dia. was drilled on the

boot.

For better guiding, the drill was made at a point that had the

reinforcement

below; so that the pin (handle) would have a longer bearing part. |

|

| First, the handle was given a shape

and

the pin inserted through the hole. Then it was bent as shown and cut to

proper length that it would catch the body when closed. It was also

bent

to a suitable profile that would eliminate any gaps. |

... ...

|

| Now you see the boot closed, and the

rear

lamps fixed on the body with CA glue. |

|

| The windshield frame was cut out from

1 mm lead sheet. |

|

|

| The windshield frame was covered with

Bare Metal Foil, and its glass was cut from acetate sheet, fixed with

white

wood glue. The frame assembly was also secured on the body with white

wood

glue.

The seats

taken from the Tamiya New Beetle

were raised from the floor by scratchbuilt plastic brackets. The

shifting

lever is from my parts box. The seats and the shift lever are fixed to

the floor with CA glue.

|

|

| The headlamps are assembled and put

on

their places, hiding away the shock absorber nuts. They are fixed on

the

body with 5-minute epoxy. |

|

| The front signals were from the parts

box. But they were rear view mirrors once. A clear lens painted orange

with clear glass paint was fixed in front of the body with white wood

glue.

They are fixed to the front of the frame with CA glue.

Rear view

mirrors are from the New Beetle

as well. They are painted in body color and fixed to the body with CA

glue,

a bit tilted upwards to let the door open freely.

|

... ...

|

|

|