|

|

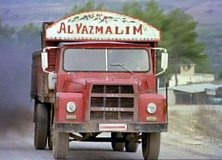

(Selvi Boylum Al Yazmalim) |

|

|

|

|

(Selvi Boylum Al Yazmalim) |

|

|

Scale : 1/24

Started:

12 December 2007

Finished: 04

May 2016

Page 1 / 9

|

|

|

|

| BMC

TM-140 is one of the milestones

of Turkish truck manufacturing industry. The BMC factory in Turkey was

founded under licence of BMC (U.K.) and manufacturing started in 1966.

The first trucks were cab-derivatives of WF series, with bend-formed

sheet metal cabs instead of die-formed body panels. The initial production was named as TM-135, which was produced in small numbers, then TM-140 was produced in 3 series during the production years. The TM-140 was a robust but a comfortless truck, with a mechanical and hard-to-turn steering wheel. These trucks have performed very tough jobs throughout the years, and many are still in operation. The model I chose to make is the truck used in the famous Turkish film "Selvi Boylum Al Yazmalim" (1978). Since no kit of this truck exists, it had to be built fully from scratch. I developed the parts from the blueprints. |