| The Lynx

ProjectLincoln-Mercury’s Lost Dream Car |

|

|

|

BUILDING THE DC-8 PLANE

Page: 4 of 11

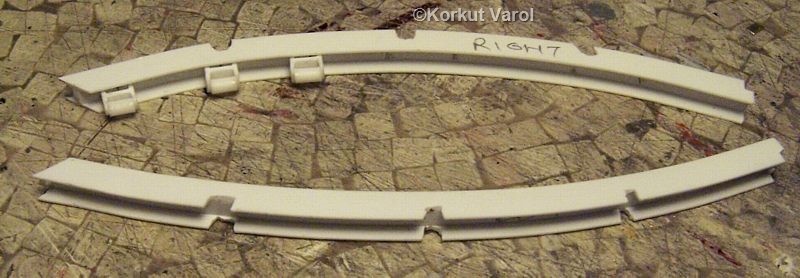

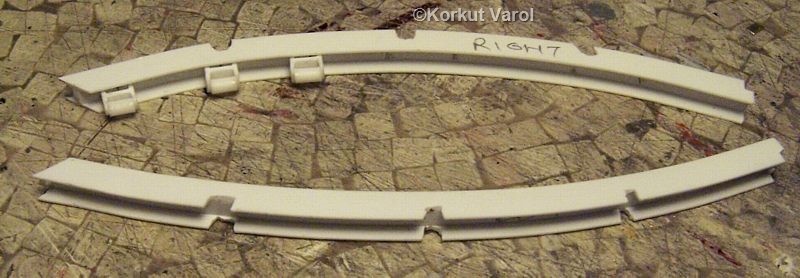

05 January 2014:I finished installing the cargo and passenger door peripheral profiles.

10 January 2014:

I

made a bending male+female die set for the H-profile, squeezed the

profile in between and set the shape by heating the squeezed profile

with a heat gun. Then I cut the necessary notches to fit the fuselage.

I began manufacturing the cylindrical rollers that the cargo net will

be installed on.

I glued the rollers inside the profile.

The photo below shows finished rollers inside right and left profiles.

I cut and shaped the passenger door outer panel from brass sheet.

11 January 2014:

I painted the rollers chrome silver and the roller brackets dark iron.

12 January 2014:

I glued the left and right parts in the fuselage with epoxy glue.

| Now to manufacture a deck net, something like this: |  |

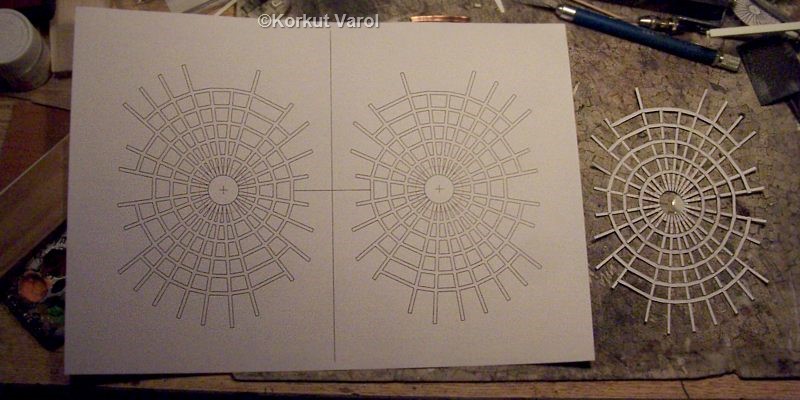

I

drew a net layout on the computer, taking into consideration, the

sagging lengths. My first attempt was to cut from paper and try to give

a shape. I cut the radial and peripheral lines separately, and glued

the peripherals over the radials.

I tried a demo on a piece of plywood, but I did not like the paper contours, despite that I had softened the paper with steam.

14 January 2014:

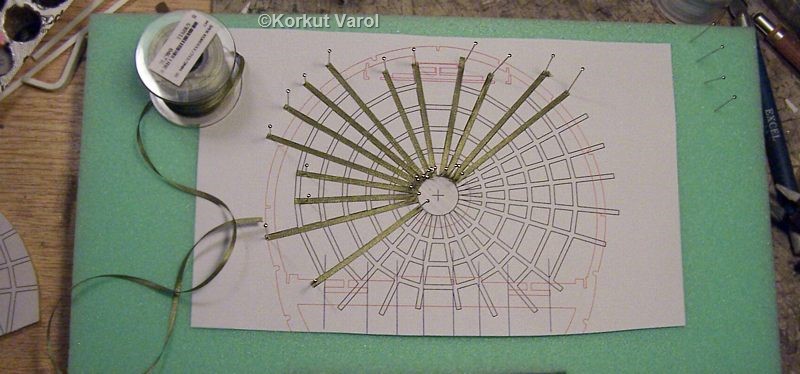

I

changed the work material to ribbon. I began by cutting and laying the

strips, but noticed that the ribbon was also too inert to be shaped to

crimpled looks, so I stopped and started again.

15 January 2014:

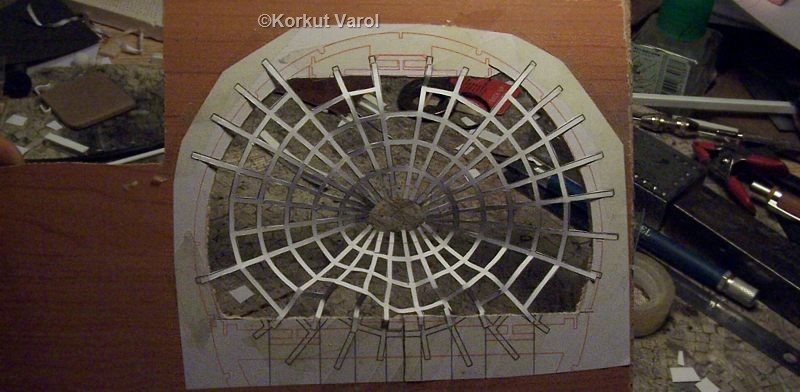

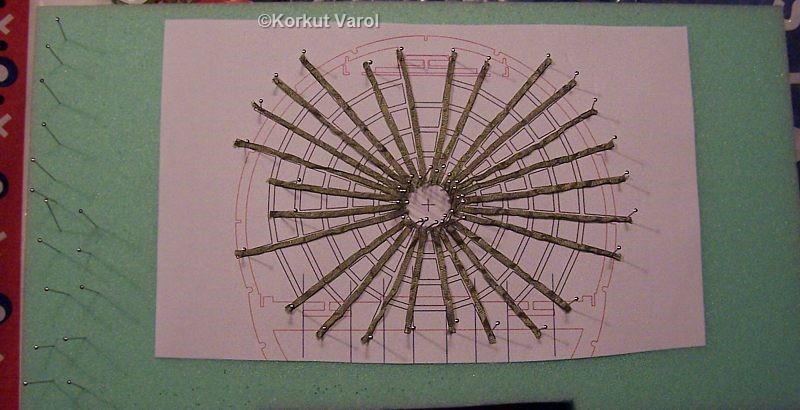

I pre-crimpled the stripes before laying on the template. I did the radials first.

16 January 2014:

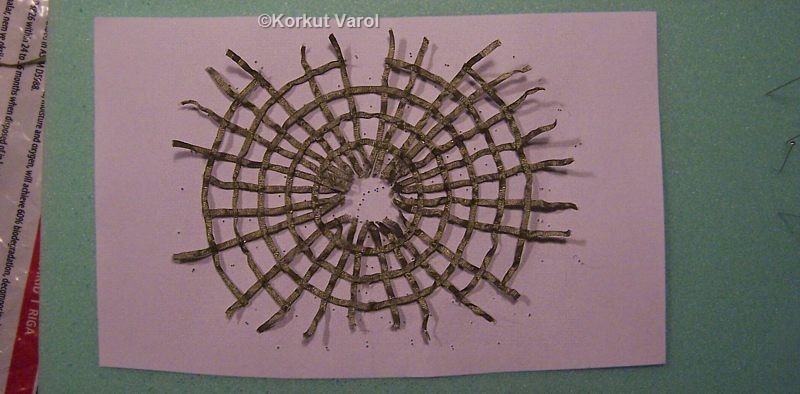

I glued the peripheral stripes over the radials and unpinned the net after drying.

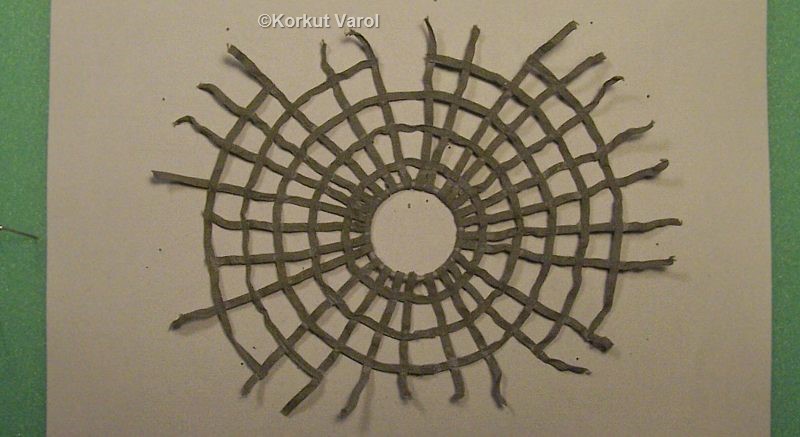

I made the central circle from copper wire,

then I installed the circle in the net. I airbrushed the net with flat grey to suppress the brightness of the ribbon.

24 January 2014:

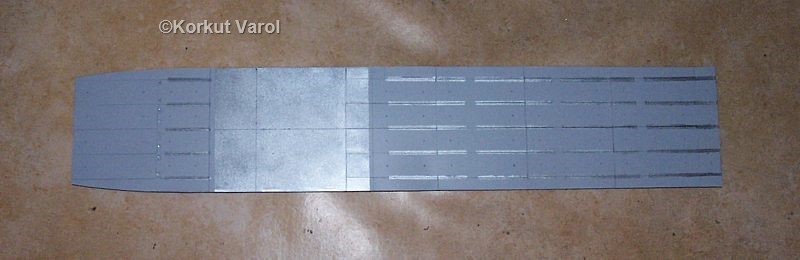

I painted the deck floor flat grey, masking the places that the rollers will be; for better adhesion.

02 February 2014:

A

new task: To hold the cargo door in open position. Although the

door will incorporate the hydraulic cylinder mechanism, this is just a

dummy for appearance and will not hold the door firmly in air. So I

thought of some other means that will be invisible when completed. I

cut strips of brass sheet and soldered them on the door skeleton.

I scratched channels in the plastic door frame to house the brass strips.

I

bent the brass strips so that the door will be held in proper angle.

This is a removeble fixture and will provide ease while working. This

will be fixed just before the outer skin is covered over the fuselage.