| The Lynx ProjectLincoln-Mercury’s Lost Dream Car |  |

|

BUILDING THE DC-8 PLANE

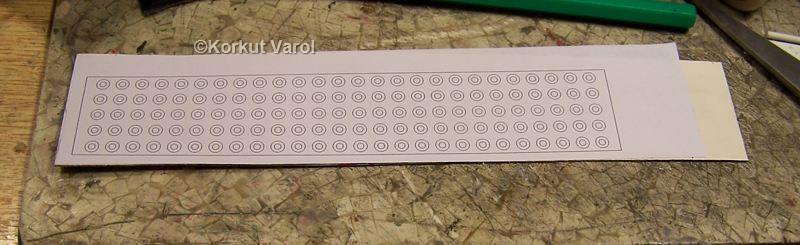

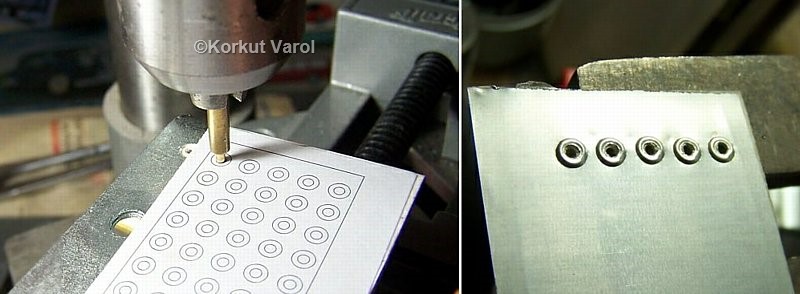

Manufacturing of floor spherical roller plates

Thinking of the subject for a couple of days, and making trials with various materials, I set on to work.

First, I made a simple punch and die utilising my drill press. No rotation, just up and down press motion. This is to imitate the flange part of the roller.

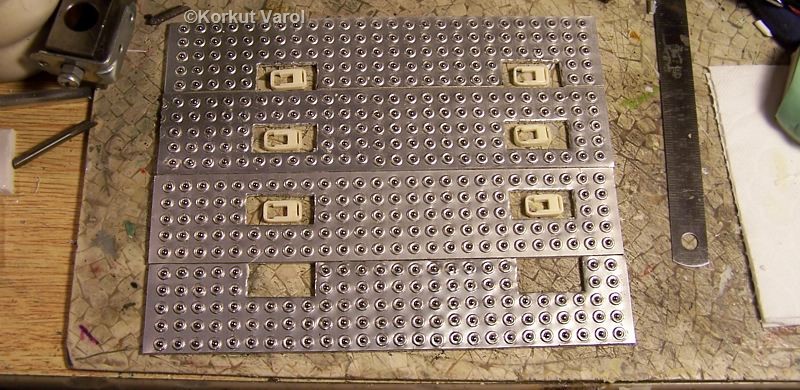

After punching and pressing the whole plate, I cut a base from 1 mm thick plastic sheet, applied double-sided sticky tape and stuck the roller plate on the base.

I temporarily installed the roller plates on the deck floor to see the matching.

20 March 2013:

Manufacturing of floor roller rails

I made the container stop lock from copper wire and plastic, and made a temporary mold and cast a sample to see how it would look like.

23 March 2013:

I formed a piece of rail from two 2.5 mm styrene L-sections, made some apparatus to cut the cylindrical rollers at the same length, and cut some number of them.

Then I prepared the master for a module of roller and stop. The length of the module is such that, when installed one after another, the pitch is 90 mm; which is compatible with 88 inch container lengths in 1/25 scale. Then I made a silicone mold and cast a resin part.

I painted the rail with aluminum, then made two covering trials for the rollers. The rollers on the left are covered with aluminum duct tape and the the ones on the right are covered with Bare Metal Foil. I liked the Bare Metal Foil appearance more.

25 April 2013:

I punched the places in the roller plates, where the container stop locks would go.

28 April 2013:

Thinking over, I did not like the brightness of the cylindrical rollers, looking somewhat artificial; so I changed the foil application to stainless steel buffing metalizer paint. I painted the exteriors of the housing rails with aluminum.

30 April 2013:

I began covering the floor with clear PVC sheets, imitating the separate panels. Why clear PVC? Simply because it was handy and cheaper than styrene sheets. I fixed the plates on the steel floor with spray adhesive.

| GO TO: | |||

| Lynx - index |  |  | |