| The Lynx

ProjectLincoln-Mercury’s Lost Dream Car |

|

|

|

BUILDING THE DC-8 PLANE

Page: 2 of 11

26 July 2012:I applied automotive polyester putty on the pylon stepwise-profile and made a rough sanding.

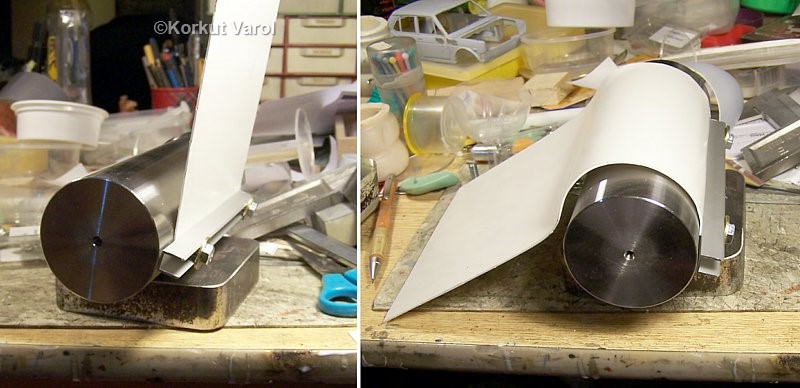

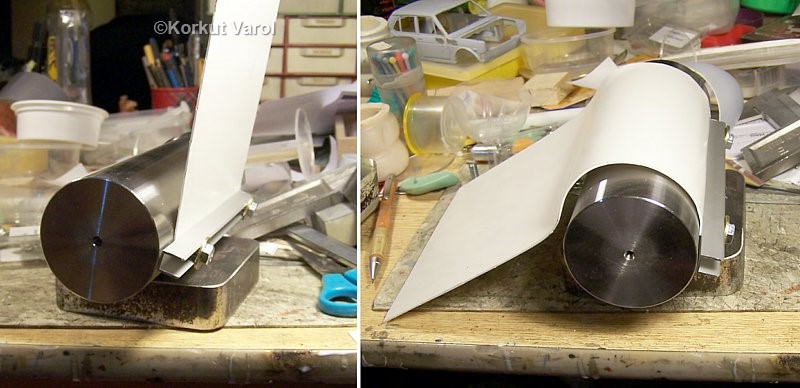

Now,

time to manufacture the two side halves of the engine cover. I made a

rounding master from iron and bent plastic sheets by heating with a

heat gun. Then I took the part off and cut along to fit on the engine

housing frame.

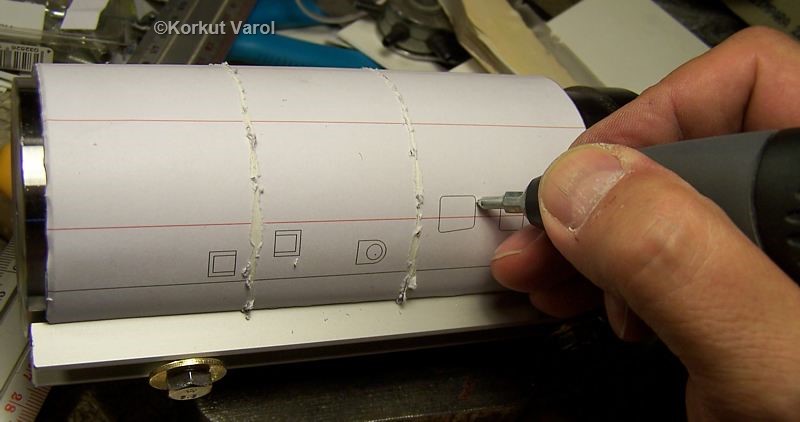

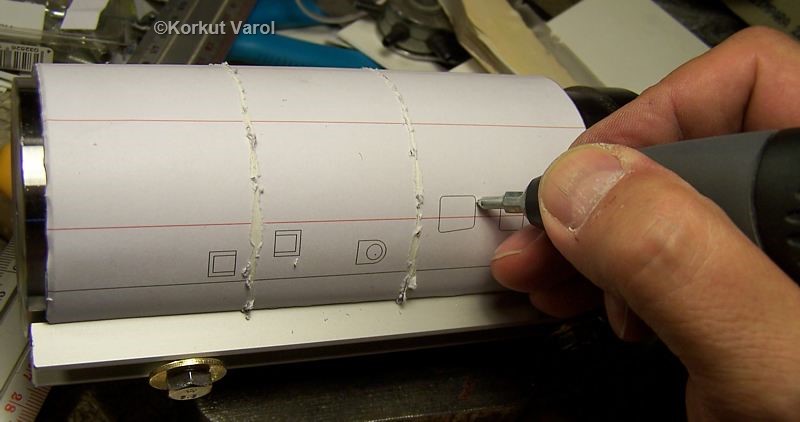

27 July 2012:I

printed on a sheet of sticky label paper, the various openings and

cover plates. I stuck the paper on one half-cover and tried to etch the

parting lines with a Dremel engraver.

28 July 2012:However, I did not like the result with the engraver, so I cut the parts and manufactured separate covers for each.

29 July 2012:

Meanwhile, I manufactured the exhaust nozzle cone parts.

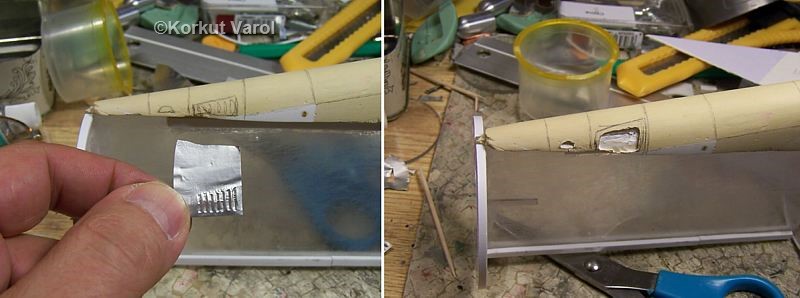

I

sketched the grille on the pylon and manufactured a sample from

aluminum foil, strengthened at the back side with CA glue+activator. I

carved out the region on the pylon to receive the back-side thickness.

I began fixing the side covers on the frame.

After fixing, I filled the gap between the pylon and the cover with automotive polyester putty.

01 August 2012:

I glued the exhaust part on the engine and fixed the engine to the wing with screws.

04 August 2012:

I cut plastic strips and glued them on the sides of the wing bulkheads to form a surface on which the wing panels would rest.

05 August 2012:

I

made an attempt to manufacture the roller frames along the cargo deck.

I took two 2.5 mm styrene L-sections, and fixed them with aluminum duct

tape to form a U-channel. I left the joining edges along the channel to

be visible, since in reality the channels are formed by installing one

module after another.

.

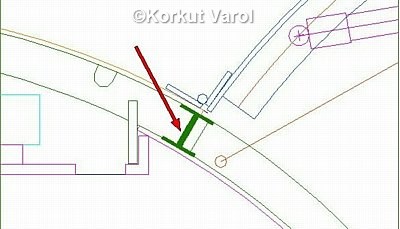

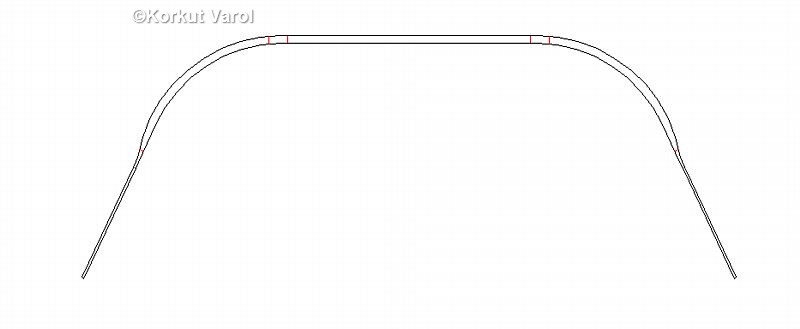

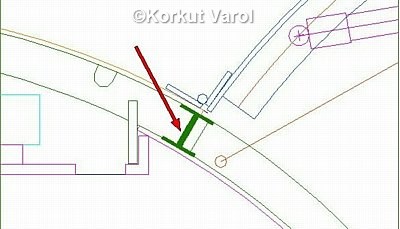

I

began getting concentrated on the cargo door area. An H-profile is to

be prepared for the periphery of the main cargo door opening. (Figure

below)

I

began with bending the corners. To bend a styrene Evergreen H-profile, I made a

bending jig from balsa and brass sheets. With the aid of a heat gun, I

bent the first corner. Then I made 3 more corners.

Then using the laser-cut development below,

I bent the corners of the cargo door frame and began epoxy-glueing the door ribs.

18 August 2012:

Epoxy-glueing

did not work fine, I accidentally dropped the frame and the ribs set

loose. So I cleaned all edges and fixed them with soldering.

I

made a pair of bending jigs to form the sides of the door gap in the

fuselage. I used an Evergreen H-beam, put it between the jigs and

heated with a heat gun to fix the bending permanently.

I

cut a straight part from the H-beam to form the upper edge of the door

gap, and glued two pre-formed corners. I glued reinforcing styrene

strips at the back side.

19 August 2012:

Manufacturing

of the lifting hydraulic cylinder. I used brass rods and tube. For the

short rods, I made an attempt with pieces of wire clips, but I deleted

them.

20 August 2012:

I

manufactured short and long rods more sophisticated, with rod eyes

closed by soldering. I also made the bracket for long rods inside the

upper door frame.

21 August 2012:

I made a temporary assembly to see the fitting.