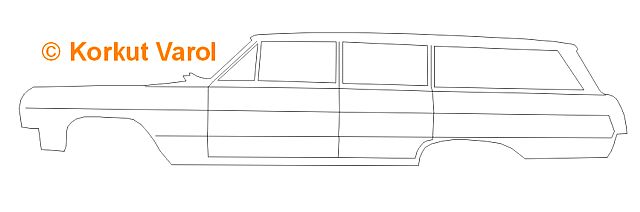

| The

first thing done was to draw a side view of the wagon. I drew this from

the collection of images I downloaded. |

|

| The

parting line of the roof was drawn.. |

|

| ...and

cut off as well as the boot. |

|

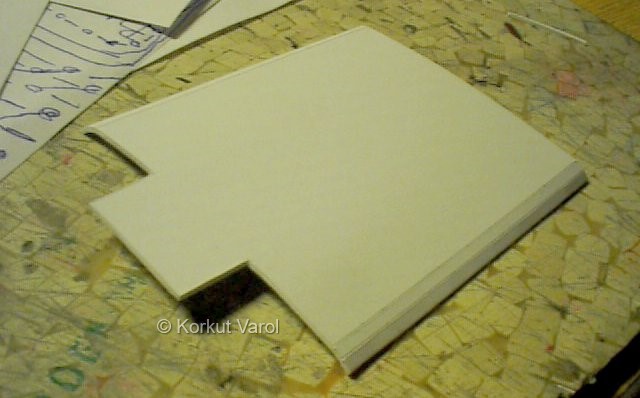

| The

roof extension was traced on a styrene sheet and cut off, then given

the

first approximate shape. |

|

| The

extension was glued to the front part. |

|

| I

filled 4 of the rear lamp holes with styrene, then opened the outermost

one with a file to accept the rectangular taillight. |

|

| I

then re-scribed the door parting lines as per 4-door body, |

|

| ...and

glued the roof extension with the D-posts. The roof will be aligned

with

the insertion of the B and C-posts.

The project

was given a break for almost 3 years, till I could start it again in

December

2003...

|

|

| Restart

on Dec.1st,2003:

I cut

away three doors, leaving the rear left in place. The reason was that

the

Dolmus cars always had them closed too, for uncontrolled operation that

might lead to danger for the oncoming traffic. The inner handles and

window

cranks were also removed at the rear left door.

I

thinned the generously molded plastic at all the opening edges.

|

|

| I

scribed in the tank cap lid for the wagon. |

|

| Dec.

9th, 2003:

I cut

styrene strips for the upper sides of the rocker panels and glued them

as two layers. The lower layer is for the fixing to the inside of the

rocker

panel, and the upper one standing for the small step that the door

bottom

will rest against.

|

|

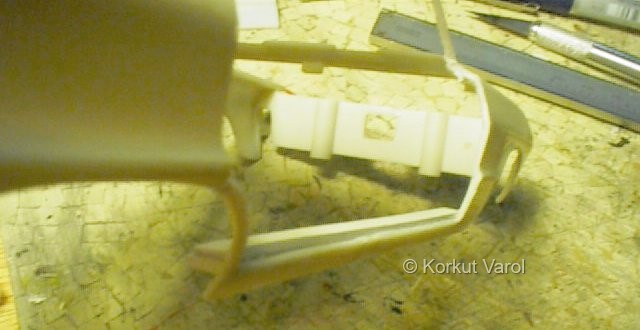

| Now

for the B-posts. After hunting on the net for several days, I could get

enough details to manufacture the real-looking inner parts. This is

also

my first attempt to open a rear door, hinged at the B-post, with the

opening

axis like the original; so that when open, it will not prevent the

front

door from opening. I first cut the backing sheets. |

|

| Dec.

14th, 2003:

The

C-post backing sheet was also cut and glued in place. Some layers of

styrene

will follow to fill the gap to the fender.

|

|

| This

is the slanted part starting below the door lock and going down to the

top of the rocker panels. Note how the edges are sanded for smooth

transition. |

|

| This

is the side covering panel for the part described above. The spacers

glued

will serve for proper positioning and fixing on the backing plate of

the

C-post. |

|

| Now

you see all the above parts glued in place. |

|

| ...then

sanded smooth. Later, putty will take care of the details. |

|

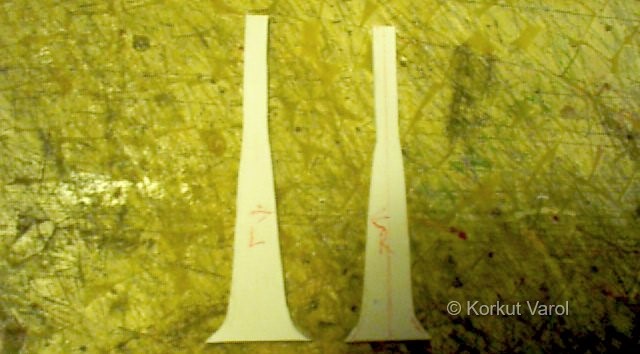

| Dec.

16th, 2003:

Coming

back to B-posts, I cut out more sheets...

|

|

| ...and

assembled them. But I did not glue them in at this stage, because the

rear

door hinging had to be manufactured and tested before glueing the

B-post

in. |

|

| A

brass pipe was cut and fixed in place with "steel putty". This is the

integral

cast two-part putty that you knead to uniform color and sets quickly.

Very

handy for adjusting the final position. I adjusted the turning axis so

that it passes right close to the lower front corner of the door panel. |

|

I

bent a steel wire from paper clip in such a manner that, of the open

ends,

the upper one is a bit longer than the lower one. This helps in

mounting

and dismounting the hinge. To mount, the pipe is first fed over the

upper

end of the wire, which clears the lower end. Then the door is left

freely

down on the lower end of the wire and it stays on, because the longer

upper

end is still within the pipe and holding it.

Now,

this wire will be tested against the B-post, and on the body. |

|

| It

took 4 wire manufacturings to get to the correct shape.while holding

everything

in place temporarily, I applied CA glue on the wire and kept still

until

it cured. |

|

| The

first opening attempt showed that there was some limitation for opening

enough. The Clashing part on the B-post was sanded down until a

satisfactory

opening angle was reached. |

|

| VOILA!!!

Now the front door can be opened after the rear door! |

|

| This

is the looks after the door is removed. |

|

|

|