| Dec.

30, 2003:

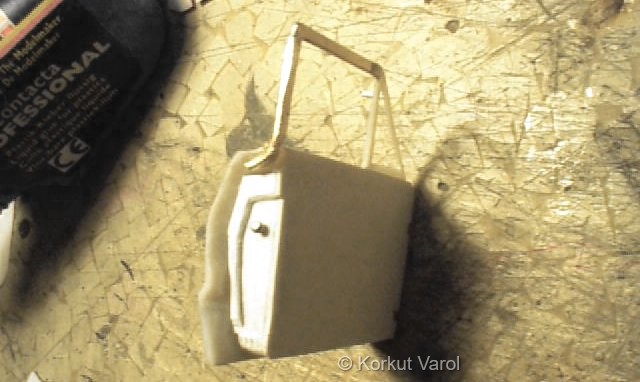

I manufactured

the back panel. What I will do is manufacture a striker plate from

styrene

and glue it on the B-post. The striker plate will hold the pin head on

the door back panel.

|

|

| I

glued the back panel to the door as shown. Now I will manufacture the

striker

plate. |

|

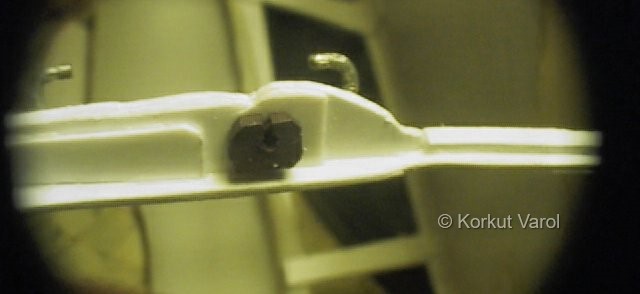

| I

cut the middle and outer layers first, and glued them. The outer layer

is now big enough to be held by hand. |

|

| Cutting

off the excess plastic and glueing in the backing plate ends the

striker

plate construction. |

|

| The

striker plate is placed on the lock pin. I will glue the striker

plate's

back, and close the door as installed. |

|

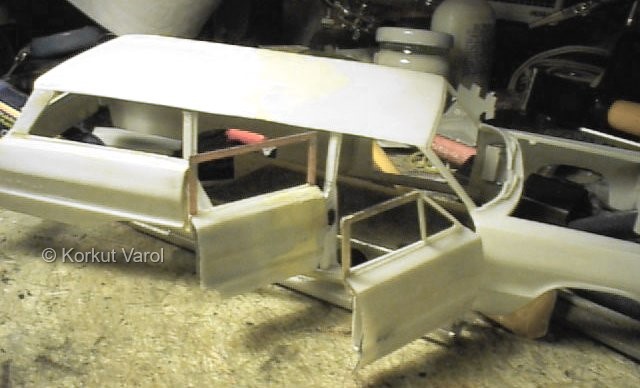

| This

is the settling stage of the glued striker plate. The plastic strip in

the front door parting line is to force the assembly, thus the striker

plate, on the B-post. The spring clamp holds the door in line with the

body. |

|

| Here

is the opened view of the striker plate after the door is opened. I did

this for overcoming a challenge, and below you will find an easier but

-I think- a better way to make a door lock. |

|

| Dec.

31, 2003:

I thought

of installing a magnet for the striker plate. I thought of opening up

an

old DC motor and utilize its magnet. I was thinking if I could machine

a magnet like a striker plate. I opened a motor and what I saw----- The

magnet was a rubber magnet! I could simply cut it with a #11 blade! A

good

New Year Gift!

|

|

I

cut the striker plate and fixed it on the B-post of the right side with

CA glue. Looks OK, eh?

The

slot is just for looks, it will not have a function of physically

housing

the lock pin. |

|

The

functional counterpart of the door lock is actually another magnet,

salvaged

from an old CD-ROM drive. These magnets are really strong.

But

since the rubber magnet was cut to so small size, its magnetic capacity

was also reduced and the attraction force was not as good as I

expected. |

|

| So

I glued a piece of galvanized steel sheet at the bottom of the B-post.

Now the pulling force was satisfactory. |

|

| Although

not being effective as a magnet, I still manufactured the rear door

striker

plate from rubber magnet too. |

|

| ..but

I put a big one right at its back! |

|

| Jan

03, 2004:

Just

an interruption to the door related topics; the rear wheel wells were

too

wide for the rear seat to fit in. So I cut out the marked portions...

|

|

| ...and

widened the space between the wheel wells. |

|

| Back

to door business, I manufactured the rear door window frame from

hammered

and filed copper wire, joining the corners with solder. |

|

| I

shaped the ends of the frame to go within the door and not to clash

with

the hinge and lock details. I had to separate the inner door panel that

I had fitted in before, to make measurements and adjustments. In the

photo

below, you see the frame being held in place and pre-fixed with two

epoxy

glue droplets on the door panel. After this cured, I assembled the door

inner panel again, and applied more epoxy glue so that the frame would

be firm in its place. |

|

|

|

| So

now the right side doors are finished too. |

|

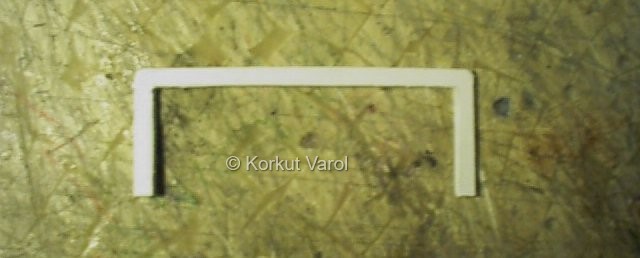

| Jan

04, 2004:

I cut

strips for all door openings, to serve as the upper flanges that the

door

frames would rest on.

|

|

| I

cut the rear left door frame from styrene sheet |

|

| and

glued it in place, also formed the rearmost side window frames for both

sides. |

|

| I

then manufactured the rear window frames from styrene sheets. Also, I

had

to correct the previously wide opened rear light holes by adding

styrene

parts and re-scribe the back door parting lines. |

|

|

|

|

|

|

.. ..

|