| August 01,

2004:

For

the battery, I needed a 3V supply

to drive the LEDs. I found a flat watch battery that went into the

spare

wheel area. What a nice fit!

|

|

| I

prepared the housing (+) for the

battery from 0.5 mm thick galvanized steel sheet and to maintain good

contact,

I applied a layer of solder on the inside. Then I soldered the main (+)

wire to the bottom and fixed the housing with epoxy glue. |

|

| To

continue with the rest of the boot

inside, I had to fix the rear "axle". I adjusted the ride height with

styrene

blocks and fixed the axle with epoxy glue. |

|

| I

prepared the boot bottom panel and

battery access lid from styrene sheet. |

|

| I

bent a copper wire and fixed it as

shown on the underside of the lid. |

|

| I

covered the whole with Duck tape

to serve as a hinge as well. A tiny screw holds the lid pressed on the

battery. |

|

| Now

to the boot hinges. I glued the

hinge and the styrene tubings to their places. The boot lid can be

taken

off anytime. |

|

| To

adjust the front axle ride

height, I hand-machined M3 screw threading to the "kingpins". After

adjusting

with nuts, I fixed the nuts with CA glue. |

|

| I

made a general assembly to check

if everything was going alright. Well, I was pleased to see it so! |

|

|

|

| For

the front grille, I cut an aluminium

piece and bent to suit the curvature. This aluminium piece comes from a

tape recorder that I had, dating from 1974! I haven't thrown this metal

part away, and after 30 years, I am making use of it... And still I

have

some more material left for the future! |

|

| I

carved out the front licence plate

space in the front bumper and also the space for the front grille. I

glued

a piece of styrene in the bumper. |

|

| I

cut out a styrene part to define

the lower edge of the front grille and glued it in place. |

|

| August 05,

2004:

I

drilled two openings for installing

two microswitches for the head/rear lamps and hazard lamps circuits. I

did not want to complicate the system with an extra division for

right/left

turn signals.

|

|

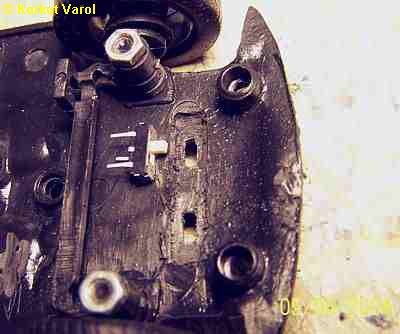

| Here

the holes are seen from the bottom.

They are hidden behind and between pulley/belt imitations. |

|

| I

fixed the microswitches with hot

melt glue gun. |

|

| August 06,

2004:

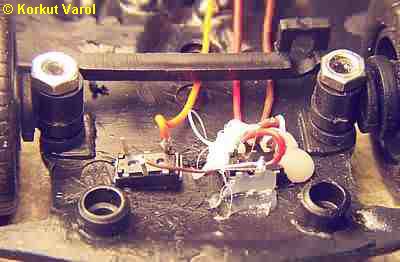

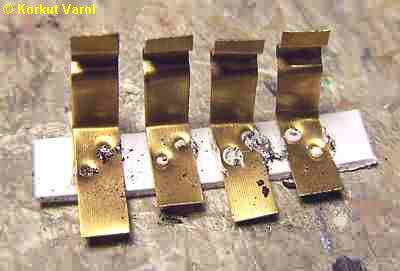

I

prepared brass contacts of the chassis,

for separation of body and chassis wiring easily. I pressed them into a

styrene slab by heating with a soldering gun.

|

|

| I

fixed the contacts better with glueing

another piece of styrene on top ofthe former assembly. |

|

|

|

|

|

|

|