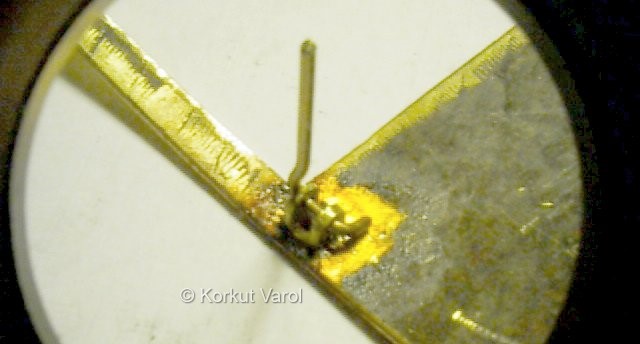

| A rod from 1

mm brass was bent and mounted

on the U-bracket. This is the trailing member of the guides. |

|

| A close-up of

the rod. Note the specially

bent profile. This prevents the link from rotating more than 90 degrees

and keeps the door at a safe distance from the body while the door is

being

drawn back. |

|

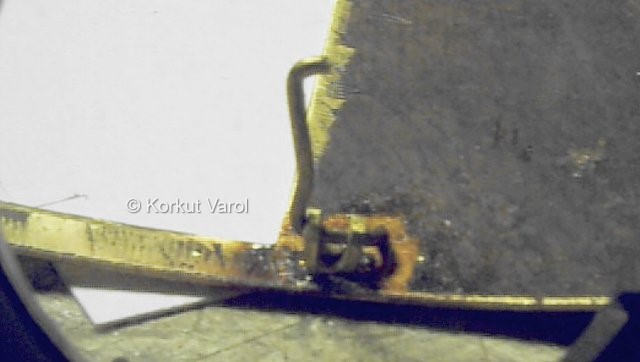

| The tip is

bent to go in the side slot

on the body and retain the link there. |

|

| The 1mm wide

side slot was cut at the

side of the body. It had to be U-shaped at the inner side to keep the

bent

tip of the link. I used steel putty to make the channel. I put a

styrene

strip at the back of the slot, covered it with wax paper so that the

putty

would not stick to it. then I applied the putty as shown, taking care

that

it does not rise above the upper level of the body slot. I let it cure. |

|

| After the

styrene strip was removed, this

was the channel. |

|

| And now, the

operation pictures of the

door. At the right, it is closed. Bottom, it is starting to open. Note

that first the rear part of the door has risen a safe distance from the

body so that it will clear the fender while travelling. At the bottom

right,

the door is now fully open. WOW !

I had started

this project as a concept,

where only the body would be enough to make. But I challenged myself to

a 1/24 scale mechanics.

If it were not

for the doors, the model

would be about to be finished by now. Anyhow, I'm happy..

|

|

|

|

| And this is

the side view with the door

open. I still have to manufacture the right side!!! |

|

|

02 July 2000:

Three

layers of styrene strips were glued

on the rear edges of both sides. These will supply "the required meat"

while sanding the rear edge radius.

|

|

| The back door

was cut out from 1 mm thick

brass sheet. Since it had a spherical profile, it was easier to shape

it

out of metal. Metal also has its internal rigidity and stays stable in

the given shape. I transferred the contour of the VW rear lamps on the

brass sheet and made the recesses with a round file as shown. |

|

| Next step was

to give the shape to the

rear door. This was done by hand and by hammering. |

|

| A test-fit

was the following step. Meanwhile,

note that the rear edges of the body were sanded to a smooth radius. |

|

03 July 2000:

The

mounting brackets of the rear door

were manufactured from 0.2 mm brass sheet and soldered on the rear door.

|

|

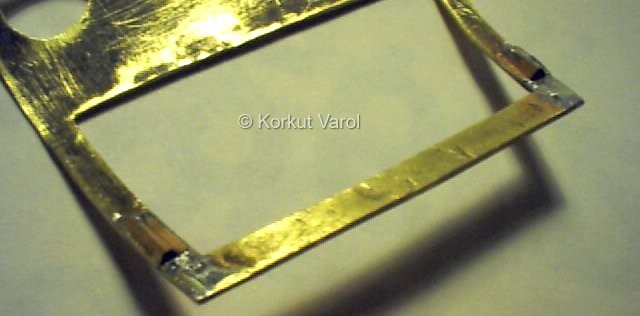

| The hinge was

made from 1 mm dia. brass

wire and the edges shown here inserted in the mounting brackets. |

|

| The hinge was

then fitted on the body,

together with the rear door for alignment guarantee. The hinge was

sandwiched

between styrene sheets. |

|

|

|