| The

rear fenders had to be widened by 7 mm on each side, so they had to be

separated from the body. I used a 0.5 mm drill to perforate the body

and

then separated it with the #11 blade. |

|

| A permanent

stress was given by hand to ease holding the parts apart when glueing

the

extensions. |

|

| The fender

was fixed apart with styrene spacers glued to the body with reinforced

superglue. This is the underneath view. |

|

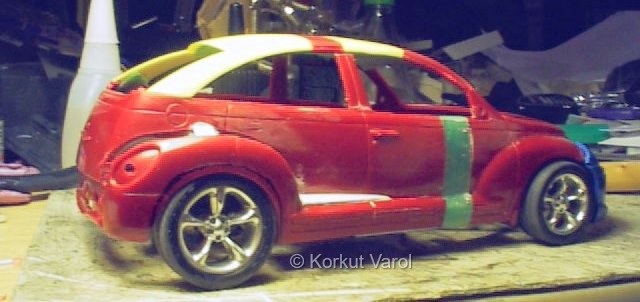

| And this is

the outside view to give an idea of how the rear fenders will look. The

gaps will be filled with styrene. |

|

| 31

May 2001:

Prowler's rear tires were

shaved inside to slip over Copperhead's wheels.

|

|

| Copperhead's

wheels also had to give their central rib away on a drill chuck as

shown,

to accept the tires. |

|

As for the

fronts, Viper tires were fitted on Copperhead's wheels, and both were

shaved

too, like the rear ones. Here you see the team of wheels ready. The

left column has Viper front tyres and the right column has Prowler rear

tyres.

The wheels'

bores were enlarged to house Prowler's axle pins, and the rolling

chassis

was put on wheels for the first time, followed by the body put over the

assembly to see the looks. The rear wheel hit the fender so the fender

will be cut from the line drawn on the fender.

|

|

|

|

|

03

June 2001:

The gap created

due to widening of the rear fenders was covered with styrene sheets. |

|

| The

width of Viper front end and Pt fenders is not acceptable as shown in

the

left pic. So I widened the Pt fenders by heating the plastic and

pushing

it outwards from the inside. The result is in the right pic. |

|

| The

gap in the chassis was also filled with scratchbuilt styrene parts. |

|

| I

modified the Prowler chassis with tubular sections ( upper picture )

and

then went on covering the rear wheels, also preparing the internal side

panels at the rear and the parting panel with the passenger

compartment.

( lower picture ) |

|

| |

|

|

....... .......

|