|

09 October

2009:

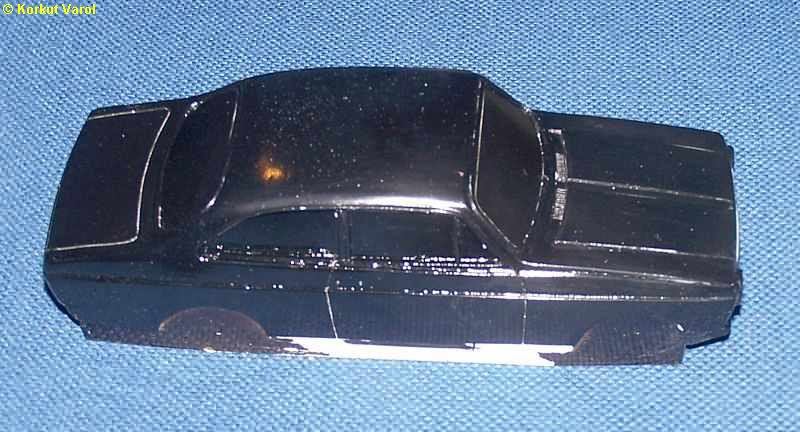

I covered all

the openings, added a molding

skirt, then sanded and painted the body gloss black to see if any

irregularities

are present. Then I went on preparing the mold.

|

|

10 October

2009:

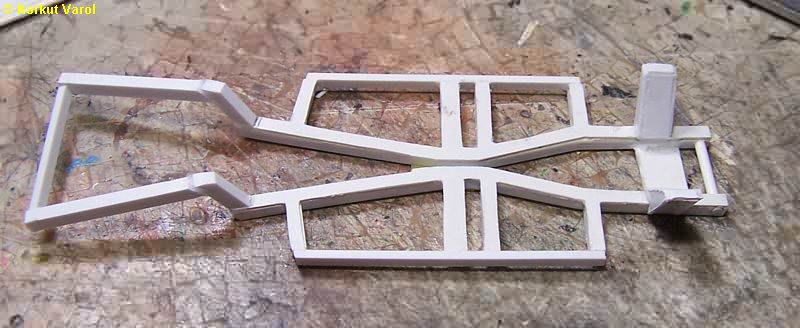

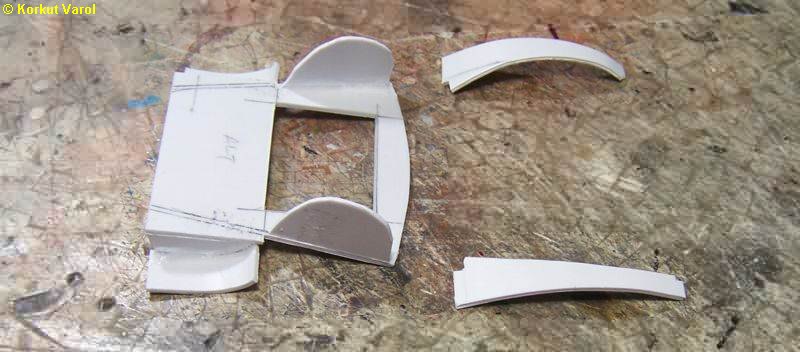

I made the

female silicone mold, then cast

a shell from resin to be the master for the male mold. I cut strips in

all axes and rejoined the parts, giving a clearance between the male

and

female parts. Then I cut the male master at an angle, to release the

part

from plaster which will be mold for the silicone male.

|

12

October 2009:

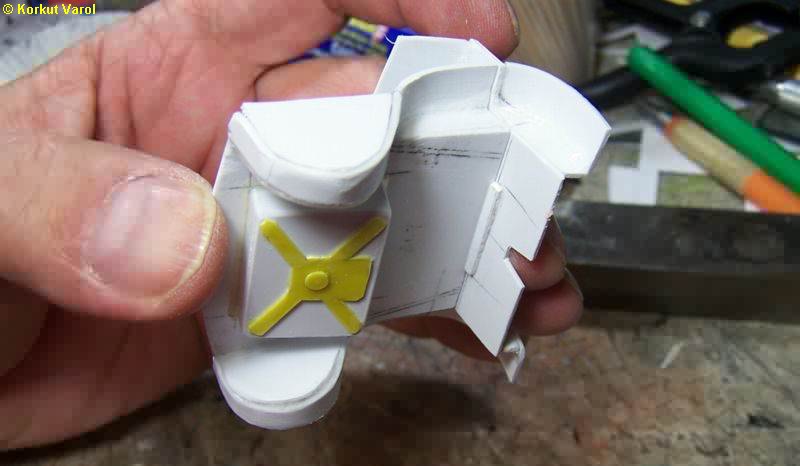

I made the

male silicone mold, then

cast two samples. The one at right is as from the mold, at the left is

machined and primed.

|

|

16

October 2009:

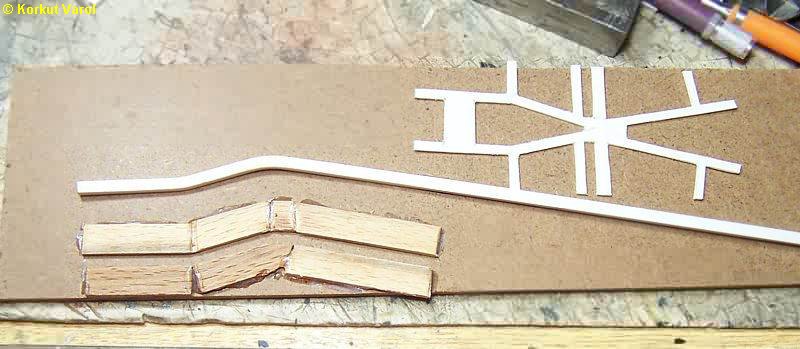

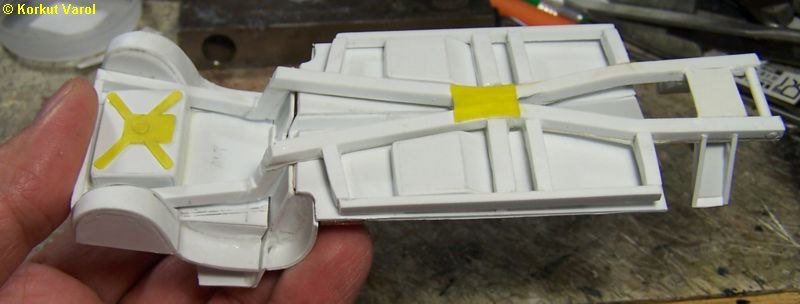

I began

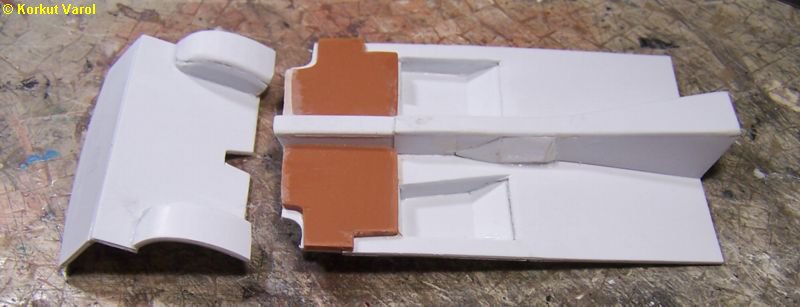

chassis manufacturing. I cut the

template with the traverses, made a bending jig for the frame members

and

bent a 4x3.2 mm styrene profile to shape by heat gun.

|

17

October 2009:

I continued

manufacturing.

|

23 October

2009:

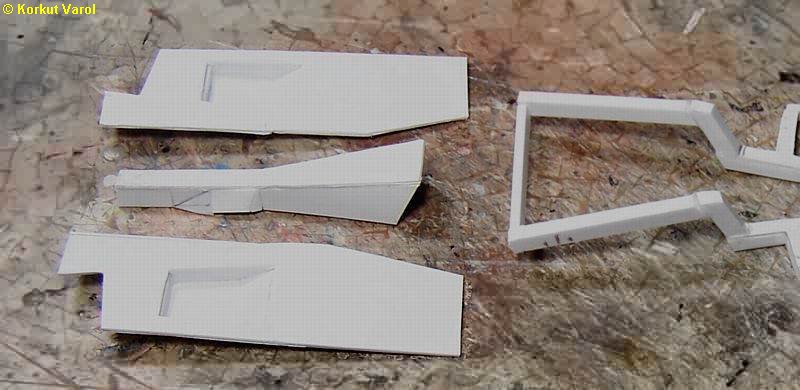

I began

manufacturing the floor panels.

|

30

October 2009:

I finished

most of the front panel

and rear seat panel.

|

|

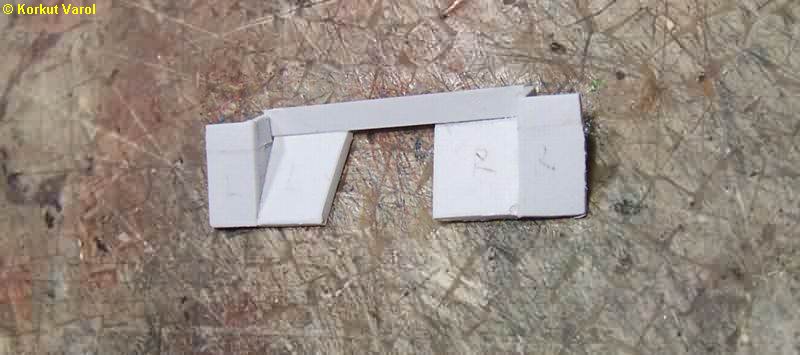

I

cut the panel parts for

the luggage floor. This view is about halfway in construction.

|

|

I

finished the luggage floor

and checked the mating with rear seat panel.

|

|

Fitting

test of the floor

panels with the chassis.

|

31

October 2009:

I started

constructing the firewall

panel.

|

06 November

2009:

I constructed

the dashboard. It took

2 full days.

|

11 November

2009:

I constructed

the dashboard mold and

cast a sample, then painted to see how it looked like.

|

|

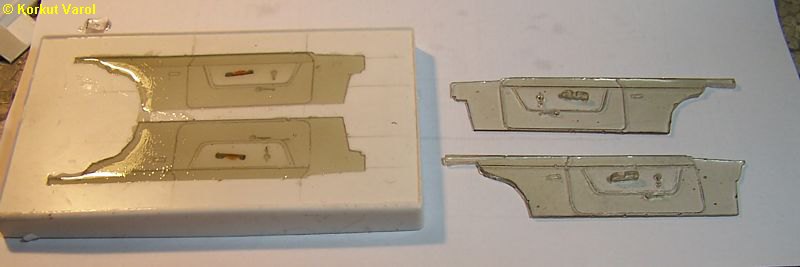

30 November

2009:

I made the

mold masters for the inner side

panels and the floor panel, and prepared the silicone molds. Here is

the

mold with poured resin (left) and a pair of cured panels

(right).

|

|

I

made a trial casting for the

floor panel. The one on the left is as it comes out from the mold and

the

right one is a trimmed part.

|

|

I

finished the mold for the boot

floor and made a sample casting. The one beside the mold is as raw and

the one on the right is as trimmed.

|

10 December

2009:

It was almost

impossible to find a scale

tyre to suit this model, so I had to manufacture them. I found an AMT

kit

tyre from my parts box, removed the necessary section to make the

required

perimeter, then joined the ends with CA glue using a circle stencil as

a jig. Then I filled the inside of the tyre with automotive polyester

putty

and sanded.

|

|

11 December

2009:

At the

leftmost is the master tyre that

I made. I wanted to manufacture from RTV silicone, so I had to make a

rigid

mold. After 3 trials, I made one from resin and cast a sample from RTV

silicone (white one). Being successful with the sample, I added black

powder

paint to the silicone and cast a black tyre (rightmost). The result was

very successful!

|

| |

...... ...... ... ...

|