13 December

2009:

I made the

front suspension assembly

master (right, brown), then prepared a 3-piece mold for casting. I cast

the first sample (left, gray).

|

14 December

2009:

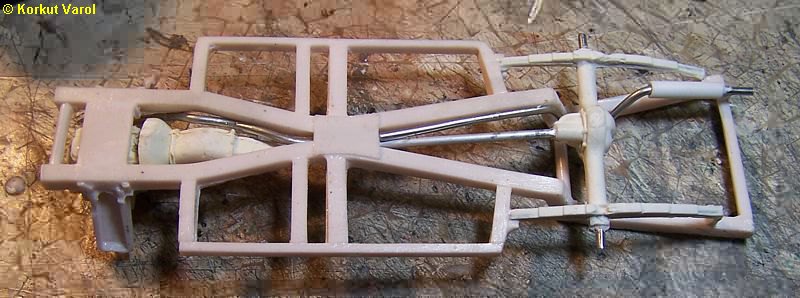

I constructed

the rear axle and suspension.

I used an axle from an AMT kit and built the springs from styrene

strips.

I will make a silicone mold from this master.

|

|

16

December 2009:

I made the

lower part of the silicone mold

for the chassis and applied liquid grease before pouring the upper part

to prevent sticking. The upright sticks are the runners for venting

during

resin pouring.

|

17 December

2009:

I cast a

sample. The one very near

the mold is the raw casting. At the rightmost, after trimming. There

are

some gaps due to trapped air but that is not important because they

will

be unseen when the floor panel is glued on top.

|

|

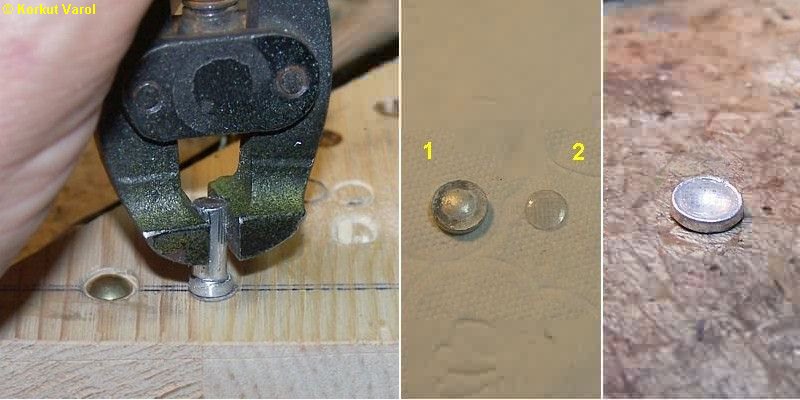

21

December 2009:

I did not like

the way that the front wishbone

assembly turned out. The casting had problems and the disc came out

oval.

I changed the design and made another, then cast a resin sample;

however,

I did not like this resin too, because it was too weak. So I thought of

casting in metal and made a casting from solder. Now this was

satisfactory.

In order to cast in one piece, the space between the kingpin and the

coil

had to be filled.

|

|

04 January

2010:

I made the

silicone molds for the rear

axle assembly. Since the cast part would be too brittle, I inserted

wire

reinforcements inside the springs and the axle. My resin casting

attempts

were a catastrophy, the upper part of the differential housing never

filled

up (left). So I cast the part using marble adhesive (right).

|

17 January

2010:

After several

attempts for headlight reflector

and bezel production, I made the production as below:

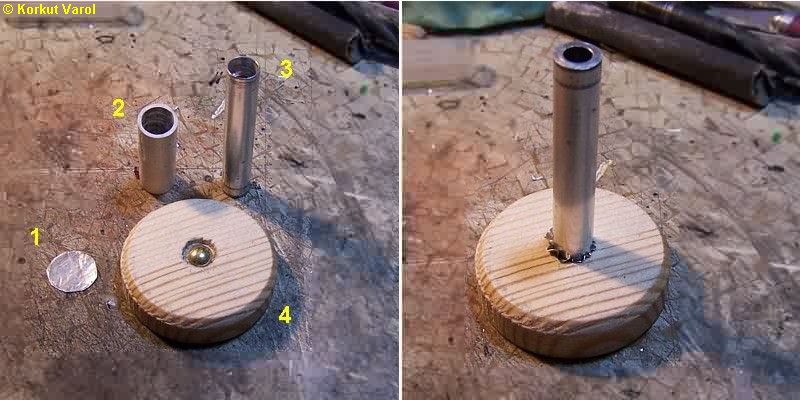

1- 0.1 mm

aluminum sheet for the part

2- Plastic

pipe piece with internal

dia. 8.5 mm

3- Male die

from 8 mm aluminum tubing

that I made by turning the inside to 7 mm dia. at the front end

4- Female die

from wood. I inserted

a metal thumbtack to form the reflector.

As in

the right photo, I pressed the

workpiece between the dies.

|

|

In

the left photo, the workpiece

is on the male die with corrugated skirt. In the right photo, I passed

the plastic pipe over the workpiece to iron the corrugations.

|

|

I

positioned the plastic pipe close

to the end and trimmed the bezel. In the right photo is the finished

part.

|

|

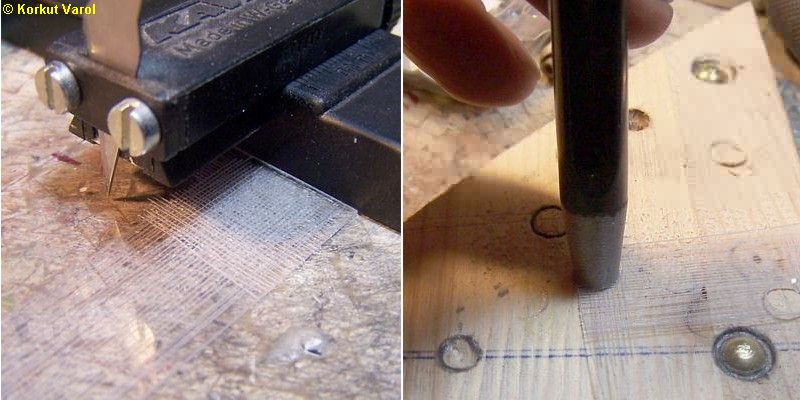

For

the lens, I made cross scratches

on a piece of acetate sheet. Then I punched out a part.

|

|

I

shaped the lens between a heated

aluminum male and the female in a piece of wood. In the central photo,

(1) I filled the back of the reflector with superglue to prevent

deformations.

(2) is the finished lens. The rightmost photo is the glued

lens+reflector.

|

|

To

make a check, I put the headlamp

on the body. The bezel height should be reduced a bit.

|

|

19 January

2010:

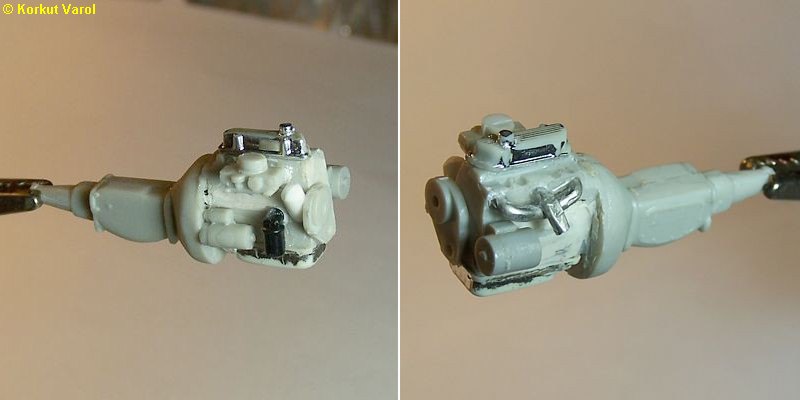

For the engine

and gearbox, I made use

of Opel GT V6 engine. I shaved the V-heads, filled the gaps with putty

and shaped the block and cylinder head. I shaped the valve cover from

Opel

GT's. I used suitable parts from my parts box for the oil filter,

starter

and intake manifold. I made the exhaust manifold from 2 mm solder wire.

I shaped the oil sump from a bigger one. I will take a silicon mold

from

this master now. Since the hood will be closed, this much detail is

enough

for the engine. The gearbox and its tail, though not exactly, are

tolerably

close to scale so I did not attempt for any modifications.

|

20 January

2010:

I made the

mold for the engine and

gearbox, and made a sample casting.

|

| I

glued the engine and rear axle assembly

on the chassis and shaped the exhaust pipe from 2 mm solder wire. Since

inserting the pipe was too tough, I made it two pieces, front and rear.

|

|

20 January

2010:

Since the

shape of the frontal exhaust

pipe was somewhat complicated, I decided to make a bending jig to

manufacture

the pipe from 2 mm dia. solder wire. I made use of FIMO polymer clay. I

embedded the original pipe half way inside, then baked in the oven to

get

it hard. The photo below shows the original pipe (above) and the

bending

jig and a formed part (below).

|

| I

manufactured the signal and stop

lamps as below. First I shaped the backside of a drill bit to the part

and drilled a female in a metal block. I heated the drill bit and

formed

0.2 mm thick acetate sheet between the male and female parts (left).

Then

I trimmed the lamp cover by a cutting knife (center), to end up with

the

part itself (right). I tried pre-painting the acetate with glass paint

and then forming, it works fine too.

|

| Due

to the space of freedom between

the parts, mounting the front wishbone assembly brought along a high

risk

of erroneous glueing. So I made a jig for glueing the front and

rear

wheels orthogonally and at at correct places to the chassis. Then, with

the wheels in place (for correct positioning) I glued the front and

rear

axles to the chassis. The wheels can be taken off.

|

| |

...... ...... ... ...

|