08 August

2008:

After a looong

hiatus, I continued working with manufacturing the bosses for door

handles. |

|

10 August

2008:

I manufactured

and glued the chrome trim frames at the rear. |

|

| I

manufactured and glued the rear vent

grilles. |

|

12 August

2008:

I applied a primer

coat. Needs some more putty+sanding.. |

|

16 August

2008:

I prepared the

RTV silicon mold setup. I glued a peripheral skirt under the body so

that

all the body would be submerged in the silicon but the silicon would

not

enter the inside. |

|

| Then

I poured the silicon in the mold.

The body floated (well, naturally..) and so I put some iron weights to

keep it submerged. |

|

17 August

2008:

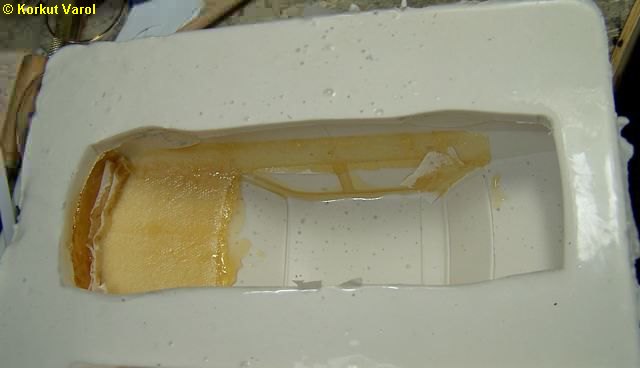

After the silicon

cured, I took off the master model and laid resin, reinforced with

tissue

paper at all sides. |

|

| Ta-daaa!!

I took off the first resin

sample from the mold. I will shave off the flashes, apply a primer and

see if there is anything wrong. |

|

31 August

2008:

The first sample

was full of cavities, so during the past couple of days I prepared a

new

female mold, taking more care this time. I laid resin surface by

surface

again, this time got a model with good surface. I will use this model

as

the gap setter between the female and male molds.

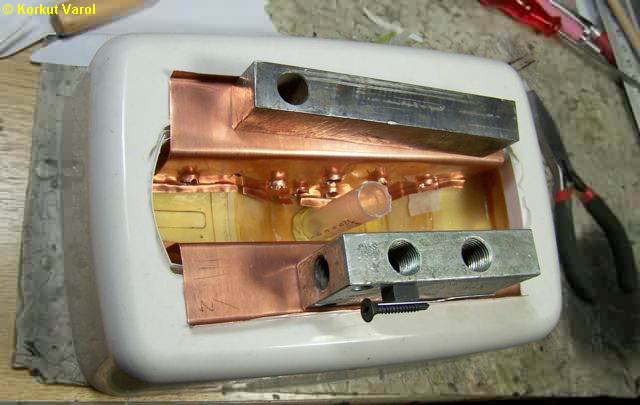

To prevent closing

of the gap due to sagging of the male mold while casting, I prepared 2

copper inserts for the male mols to act as a skeleton. I drilled holes

here and there, to facilitate the spreading of silicone while pouring,

and to act as gripping elements between the silicone and the metal when

cured. |

|

| To

provide some means for exact positioning

of the male mold, I bent the edges of the copper sheets to form a

resting

surface on the female mold.To prevent distortion while pouring

silicone,

I put some iron weights on the copper surfaces. I made a filling runner

from the body of a plastic injector and fixed it inside the roof. Now

the

setup is ready for silicon pouring. |

|

| I

poured silicone to form the male

mold. I hope all end up alright... |

|

01 September

2008:

Unfortunately

the male mold did not easily come out of the body and the body was

broken

while stretching. I will try a multi-piece male mold. |

|

05 September

2008:

To produce a

flexible body, I applied a shell of plastic with a glue gun. |

|

| And

I got a flexible body shell to

make the 2-piece male mold. |

|

06 September

2008:

To smoothen the

traces of the glue gun on the inside, I covered all the inside with

masking

tape. I poured the slicone for the first part. I put a non-drying

molding

paste inside, with a slant so that the two pieces could be taken apart

easily. After it cured, I covered the whole surface with Humbrol Maskol

so that the second poured silicone would not stick to the first one.

Then

I poured the silicone in the second part. |

|

08 September

2008:

I used acrylic

polyester resin and BINGO! The part was very acceptable.. The black

rectangles

embedded in the body are styrene spacers that I put between the male

and

female molds to prevent touching. |

|

29 March 2009:

The top contours

of the windshield was incorrect, so I corrected the master model and

made

a new female silicone mold. I made a new body and cut out the windows,

wheelarches etc. I also prepared a mold for the floor and got a sample

casting, but I have to work on it more. |

|

03 April 2009:

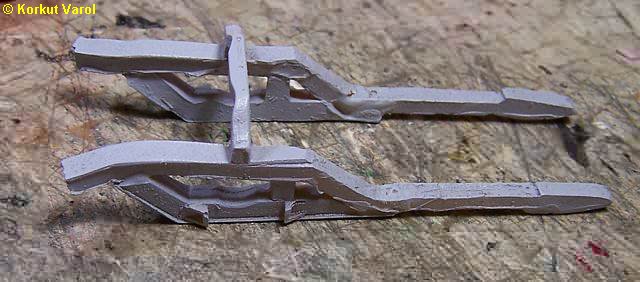

I made silicone

molds for the front chassis arms and cast resin parts. |

|

| I

joined the parts with CA glue and

applied primer paint. |

|

|

|