03 April 2009:

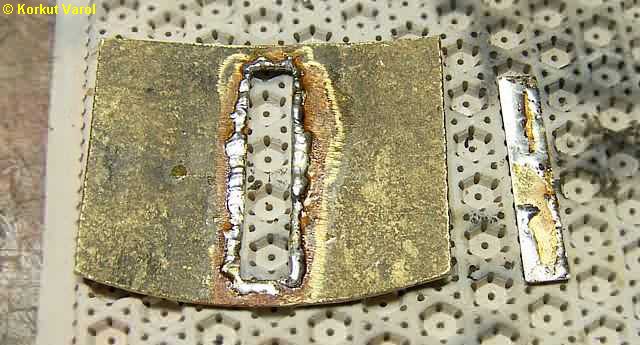

I cut out the

hood and the whole area in front of the radiator (as in the real car). |

|

| I did not want

to deal with resin for the hood, so I decided to manufacture it from

0.70

mm brass sheet. I tailored the part and formed it to the curvatures of

the body. To depict the formed part at the center, I cut it off. |

|

I

cut a strip from 0.3 mm brass sheet

to fit in the recess of the hood.

I pre-soldered

both parts all around

to prepare for the joining. |

|

| I soldered the

central part flush with the inside of the hood, so that the pressed

form

rectangle was depicted outside. |

|

| This is the raw

hood... |

|

05 April 2009:

I began to cut

out the hole that serves for under-hood heat rejection. Also, I drew

the

underhood reinforcement on the computer, printed, then stuck it on 0.7

mm brass sheet with double-side adhesive. I drilled the pilot holes for

the cutouts. |

|

| I

completed the discharge hole, and

prepared a master for its cover from balsa wood. |

|

| I

finished the reinforcement and glued

the two parts with CA glue. |

|

| To

manufacture the cover, I had to

make

a male and a female die. First, I made a mold of silicone, from the

balsa

master; and made the resin male die (left). Then, using a mold

seperator

fluid, I applied automotive polyester putty on this male and formed the

female die. I put 0.1 mm thick aluminum foil in between and made a

"pressing".

To add strength, I applied CA glue on the inside with activator. I cut

off the rear surface and trimmed the peripherals. Now the cover is

ready

to be glued on the hood. |

|

06 April 2009:

To make the hood

open, I manufactured the front central panel/frame from 0.3 mm brass

sheet

and soldered housings for the hood hinges. |

|

| After

a whole day's trial and error

attempts, I managed to manufacture a pair of properly working hinges. I

made a pair of housings for the hinge wire under the hood, and fixed

them

with CA glue. Not 100% realistic, but still better than a non-opening

hood... |

|

07 April 2009:

I installed the

inner wheelarch panels with CA glue. |

|

09 April 2009:

The tire that

I had cast previously was a little small in scale with the car. So I

began

searching for a new suitable tire. I found a diecast Citroen C3 model,

the tires being good in outer diameter but wider than required. Also

the

aspect ratio was lower than the needed. However, the tread pattern had

large teeth, suitable for a rally car. So I went on making a new tire,

using the rubber one. First I inserted a suitable part inside, then

made

a silicone mold from this and cast a half tire from resin. I had the

part

turned to 15 mm diameter at the inside and cut at half the tire width.

Now this will be the master for the new half-tire mold. |

|

10 April 2009:

I made the luggage

compartment seperator panels from resin and plastic. I also glued the

front

chassis arms to the floor and firewall. |

|

11 April 2009:

I made the master

for the dashboard (left) from balsa and styrene sheets. Then I made a

silicon

mold and got a resin copy (right). |

|

| For

the rear axle, it was impossible

to bend a wide profile section. So I thought of forming the whole by

layers.

I used 3 rectangular strips to make for the width of the beam. I drew

the

rear axle profile on a piece of wood and cut a shaping master channel

with

my Dremel. I used a heat gun to form the strips in the channel. The

formed

strips were glued to make the raw beam. |

|

12 April 2009:

I manufactured

other items on the rear axle from styrene sheets and completed the item. |

|

14 April 2009:

For the glasses,

I copied one male and one female sections from both the front and rear

windows, of automotive polyester putty. I used the pairs as dies for

acetate,

After pressing with a clamp, I applied heat from a heat gun to form the

windows. |

|

One

of the toughest deals was to manufacture

the wheels.

(1)

I founda a suitable

diameter wheel from my parts box.

(2)

It took me two days

to make the central parts from styrene sheet as the master. Then I made

a silicon mold.

(3)

The cast resin raw wheel

(4)

The complete wheel

and tyre as painted. |

|

|

|