| Now the central cross-members

have to be constructed. The original chassis seemed to be weak in

construction

to take up the stresses of a powerful machine, so the cross-members

were

built without being faithful to the original. The material used is 0.2

mm thick brass sheet. The developments are traced and cut out.

Lightening

holes were drilled before bending. Pliers were used for

bending. |

. .

|

The two sides

of the central cross-member

are now united with a central section. This central section seen was

later

cancelled because the transmission had to be there, or else the engine

would be too much in the front. |

|

| The side frame and central

cross-member are joined with solder. To do this, first the mating

locations

on the surfaces of the members are covered with solder, then brought

together

and heat applied with the combined pressure of soldering iron from

above.

The soldering iron has to be at least 100 Watts to give in heat faster

than it dissipates through the metal. The pre-solders between the items

melt and firmly hold the pieces together. Be sure to have a

low-conductive

material (wood is OK) below the workpiece, to keep the heat within the

workpiece. |

|

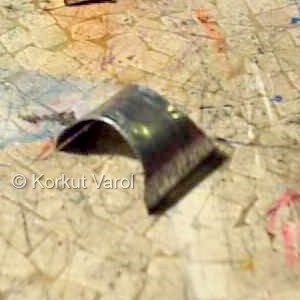

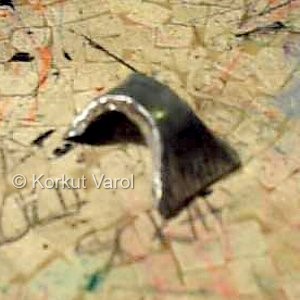

| The front transverse

member is still from 0.3 mm galvanized steel to be strong. The first

pic

is primary bending after development cutout. The second one is the

final

shape given with round pliers. |

.. ..

|

| Now the chassis is semi-complete

with the addition of the rear transverse member, having lightening

holes

on it. The front member was soldered with fill-in technique because the

items did not have flat mating surfaces. Note the center part is

removed

by now. |

|

| This is the last transverse

member to be located at the very back of the central cross-member, also

where the front brackets of the leaf springs be located. The bottom

part

is curved to provide space for the driveshaft motion. |

|

| The chassis is shown

with the above mentioned member put in place. Also, two engine mounting

brackets are soldered in place. The center element is replaced by a

tubular

member. |

|

| On the left is the upper

bracket that will carry the helical spring and the tip of the shock

absorber.For

the circular pressed part, a wooden male and female die parts were made

and the pressing was obtained by light hammering on the male. The rest

was bending with appropriate tools. The inside of the bend was

strengthened

with filling solder. On the right, you see them mounted on the chassis.

Below these units are the parts to hold the wishbones but I was so

concentrated

on the work that I forgot to take their pics. |

.. ..

|

| This is the bottom view

of the front end. Two brass rods were soldered between the lower

wishbone

bracket edges, also taking strength from the center of the front

transverse

member. |

|

| This is the front ass'y

without the springs and shocks. The wishbones were bent to a special

profile

to make room for the spring. Pins were soldered at the ends of the

wishbones,

the brackets on the chassis were opened a bit wide to fit the wishbones

in their holes, then closed to original position to hold the ass'y

without

letting it loose. |

|

| Testing the linkage

motion before spring and shock absorber assembly. |

|

| The front shock absorbers

are made from brass rod machined at the end to form the lower eye, and

the upper part from brass tubing. On the top, the head part of a nail

is

cut to 2mm. length and soldered to the tubing to form the upper

connection. |

|

| On the right is the

assembled view of the front suspension. The white PVC on top of the

shock

absorber is a temporary "nut" to keep the upper part of the absorber in

place. |

|

| The testing

of the assembled front suspension. |

|

|

|