Now, some start for the body

construction.

Following are the steps

in forming the

door skin. First, the blanks are cut from 0.2 mm brass sheet. |

|

| For long straight bends, I use a

hand-made

tool as shown. The first bend was made as shown. |

|

| Follows the second and third bends in

the same manner. |

|

| And, finally, the curvature of the

top

section was given by smooth bending with pliers. |

|

| The floorpan was cut and bent as

shown... |

|

| ...and soldered temporarily on the

frame. |

|

| The boot skin was cut and bent to

profile

by hand. |

|

| The cockpit back was also cut and

bent

(shown halfway during bending) |

|

| The edges that will be joined are

pre-soldered

at their meeting ends. |

|

| The metal was too big and heat

absorbent,

so soldering iron did not work here. I used a small torch to join the

parts

together. |

|

| The boot and the cockpit rear are

joined

first, then they are soldered to the floorpan as shown. |

... ...

|

| The sides of the boot were cut from

sheet

brass. |

|

| The 'B-post' region was formed by

bending.

To bend it smoothly, the to-be-bent section was cut and then the body

profile

given. To smoothen the surface, both the inside and outside of the bent

part was covered with solder and then ground smooth with Dremel

moto-tool. |

. .

|

|

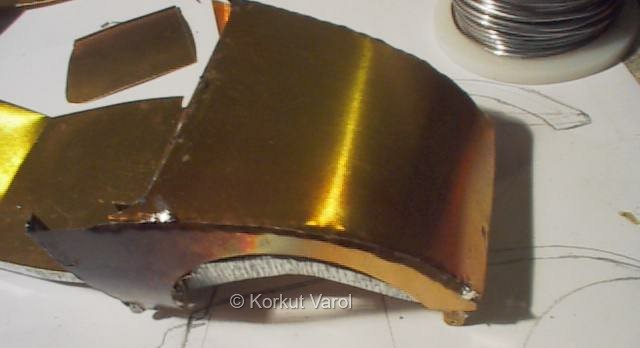

| The boot top and side panels were

point-soldered

to hold the parts together while soldering. Note that the matching

edges

were slightly bent to form a pre-curvature. |

|

| The parts were joined by a fillet

solder

from the inside. Generous solder was applied so that there would be

enough

metal while grinding to shape. |

|

| Here you see the Dremel in action of

giving

the proper radius to the edge. |

|

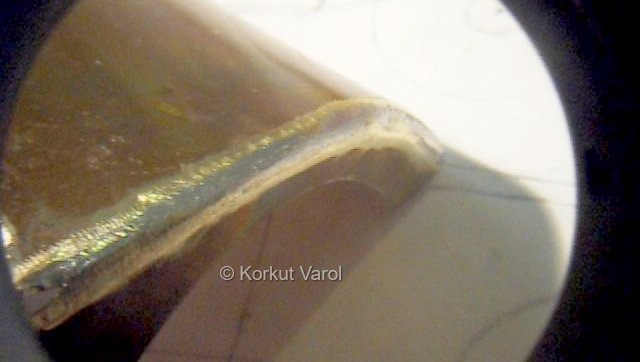

| A close-up shows how the solder is

exposed

after grinding. |

|

|

|