| The rear wheel wells were prepared by

cutting to smoothen the bend and fillet soldering. |

... ...

|

| The wells were soldered to the body

at

the inside and their bottom parts trimmed to mach the chassis contour.

The fillet solder was then ground with Dremel. |

... ...

|

| This is how it looks after

grinding. |

|

|

The areas

where the doors would be

were marked to be cut. They were cut off by Dremel.

|

|

|

| Now back to the doors. The internal

panels

were cut as a development, and bent to shape with pliers. A

test-fitting

to see how they fit. Note the gap left for the glass. |

... ...

|

| The door panels were joined with

solder.

Pre-soldering was made on the mating edges with soldering iron. The

parts

were joined by applying the heat of a torch. |

|

|

| A test-fit with the doors to see if

everything

is OK. |

|

| The rocker panels are prepared by

cutting

out a development and bending with pliers. This is a critical part

because

it has curvatures in all 3 axes. Note point solders inside. These were

put at the places of irregular protrutions after bending, as filling

material.

They were ground smooth afterwards. |

|

|

| The rocker panels were soldered to

the

body with the doors in place. |

|

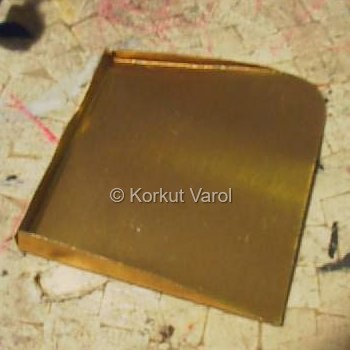

| The windshield panel in raw formed

shape.

The bendings were made with round pliers. |

|

| The windshield panel is soldered into

place . |

|

| Imperfections in the bends ground by

Dremel. |

|

| The recess panels between the

floorpan

and the rocker panels are formed and soldered into place. |

|

|

|

|